New battery test centre opened by TÜV in Germany

The German technical inspection agency TÜV Rheinland has opened its Battery Test Centre in Aachen. The facility is said to be the most modern independent test centre in Europe. Not only electrical tests and durability simulations can be carried out there, but also safety tests up to the destruction of the battery.

As reported when the project was announced in October 2020, the test centre has been built in the Dutch-German innovation park Avantis. TÜV Rheinland and its partners have invested 24 million euros in the approximately 2,200 square metre laboratory, according to the announcement. When fully operational, it will employ 25 people.

Traction batteries weighing up to 800 kilograms can be tested in the facility. The maximum dimensions are 2.30 metres long, 1.60 metres wide and 40 centimetres high. According to TÜV, the energy content of the batteries to be tested can be up to 150 kWh. With this, the testing organisation sees itself well positioned for the coming vehicle generations – in most vehicles, the batteries weigh between 300 and 600 kilograms.

This is not about independent testing of batteries in used electric cars, but about homologation – the type testing of new motor vehicles or, in this case, new motor vehicle components. The batteries installed in new vehicle models must meet different safety standards. This is precisely what TÜV Rheinland wants to be able to test in the facility. Specifically, this involves the international standards GTR 20, UN 38.3 and LV 124, the US-American standards SAE J 2224 and SAE J 2029, the ECE R100, which is essential for the EU and Japan, GB 38031 for China, KMVSS for South Korea and AIS-048 for India. The UN 38.3 mentioned above, for example, sets requirements for the transport of traction batteries.

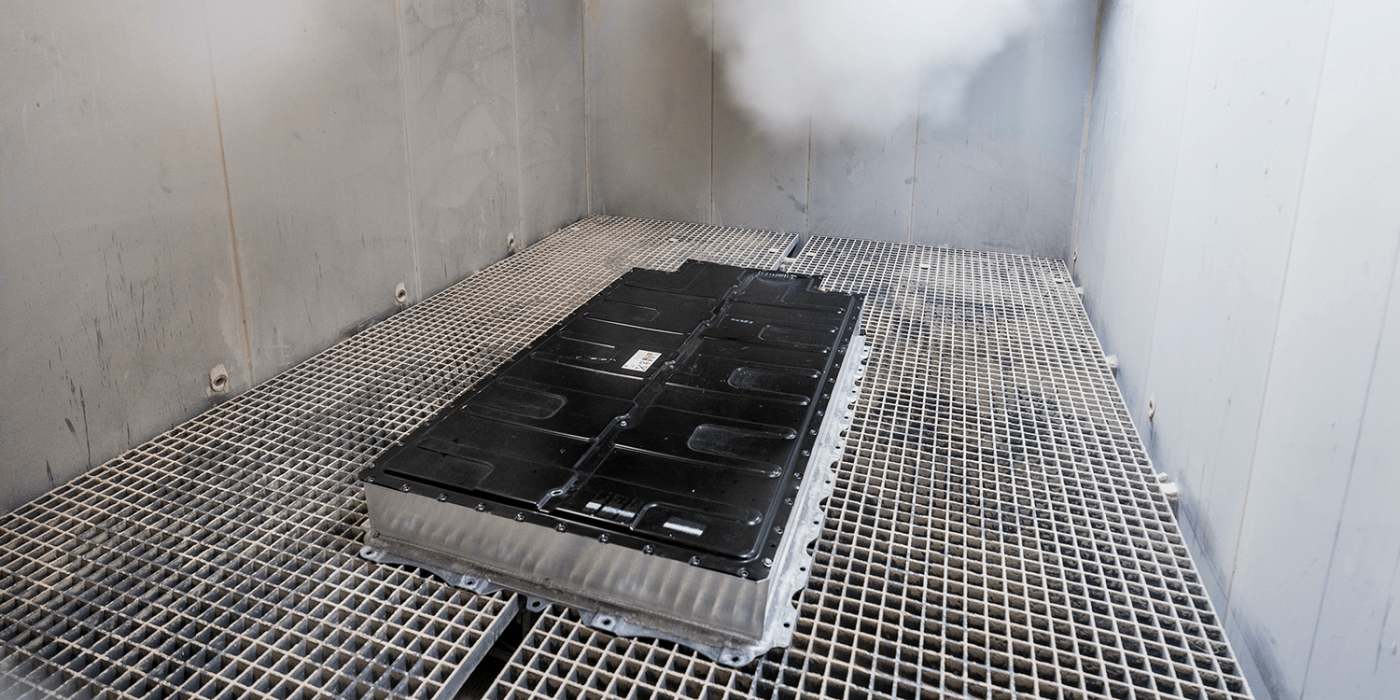

Own bunker for battery destruction tests

The tests cover electrical safety and reliability, performance and special climatic and environmental stresses. Mechanical and durability tests are then carried out before the destructive tests follow. These tests determine the electrical, thermal or mechanical load limits of the battery.

In order to be able to carry out these tests precisely, seven climatic chambers were built during the 18 months of construction, for example, which can simulate temperatures between -60 and +90 degrees Celsius and a humidity of ten to 95 per cent.- There is also a salt corrosion chamber, a chamber for dust testing, a shaker for simulating vibrations and shocks as well as a test stand for surge water (test chamber according to LV124). On one of the 16 battery test stands, the electrical tests as well as the simulation of the service life can be carried out. The destructive tests are then carried out in a special bunker facility. The facility, which measures 8x7x8 metres, is designed for drop tests, nail penetration, over- and deep discharge, pressure, crushing and fire simulation.

In addition to the type tests, tests of prototype batteries are also possible, which should support the development – so that the later series product complies exactly with those standards. This is exactly the kind of development that is going on at a rapid pace. “The dynamics in the field of electromobility are extremely high. Manufacturers are entering the booming market with more and more new models,” says Michael Fübi, CEO of TÜV Rheinland AG. “Our goal is to contribute to making electromobility safe and at the same time accompany innovations with the work at our new location in Heerlen-Aachen.”

“Innovation in the field of electric vehicle batteries is at an all-time high – accordingly, independent testing capacities are important,” says Achim Kampker, head of the Production Engineering of E-Mobility Components (PEM) chair at RWTH Aachen University at the commissioning of the laboratory. “Durability and costs, material use and performance, range and recyclability: these are central aspects of battery development. The testing services of the new test centre contribute to a higher reliability of the technologies, but also to marketable innovations.”

Reporting by Sebastian Schaal, Germany.

Source: Info via email

0 Comments