Lightweight and flame-resistant thermoplastics for fire safety in electric cars

Until now, the use of plastic components to prevent or delay thermal runaway in batteries has been taboo. These components have generally failed to meet the automotive industry’s testing standards for electric drives. Now there is Quantix ULTRA: The new material class from Freudenberg Sealing Technologies. It meets all requirements with flying colors. And it is already in series production: A major car manufacturer is installing flame protection barriers made from this material for cooling system parts in the lithium-ion battery of an electric car.

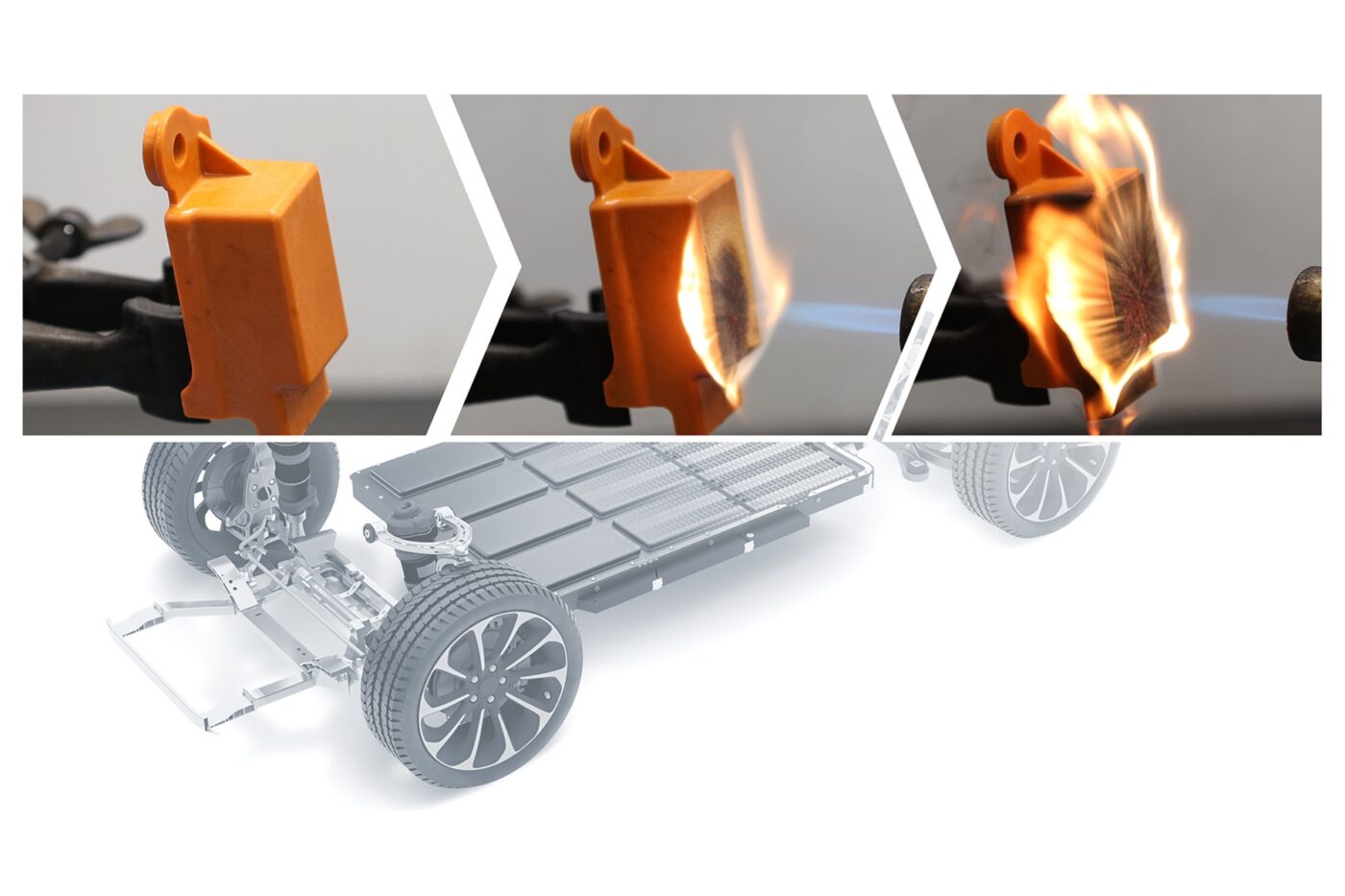

Quantix ULTRA has impressive features. This material class can withstand very high temperatures without melting or igniting. In laboratory tests, a two-millimeter thick material sample can even resist an applied flame with a temperature of 1,200 degrees Celsius for over 25 minutes. This flame resistance puts Quantix ULTRA at the top of all currently known technical plastics.

Additional tests have simulated the emission of hot particles under high pressure, a possible scenario if the gases in battery cells are abruptly discharged. Quantix ULTRA withstands the stress test for 20 seconds. A two-millimeter thick aluminum sample only takes two or three seconds to be destroyed.

Quantix ULTRA is ideal for any application demanding superior fire protection and lightweight design. Its compatibility with injection molding removes design constraints, enabling the fulfillment of virtually any customer requirement. This includes, for example, the convenient integration of mounting clips into the desired component during manufacturing. High unit numbers are just as possible as the production of large components in short cycle times.

The material can also be processed into films, for example, to be implemented in battery-electric drives. Other areas of use include enclosures for power supply units, media-carrying lines, cable insulation, battery housing covers and components for electric motors.

All these properties make Quantix ULTRA a highly desirable material for electric vehicle applications. Freudenberg Sealing Technologies is once again demonstrating its innovative strength in the field of electromobility.

This is a sponsored article and the client is responsible for the content. If you’d like to inquire about similar opportunities, please get in touch via advertise@electrive.com.