MAN begins mass production of electric trucks

Calling it a ‘historic moment’ for MAN Truck & Bus, MAN CEO Alexander Vlaskamp said the shift marks a ‘turning point’ in the company’s history: “We have invested almost €400 million euros in research and development to be able to offer our conventional truck product portfolio with battery-electric drive as well… We aim to deliver the first 1000 electric trucks by the end of the year.” At a ceremony in the Munich plant, it was Vlaskamp along with MAN Production Director Michael Kobriger and EPP Chairman Manfred Weber MEP who hit the start button on production. This follows the first delivery of an eTGX to customers in October 2024.

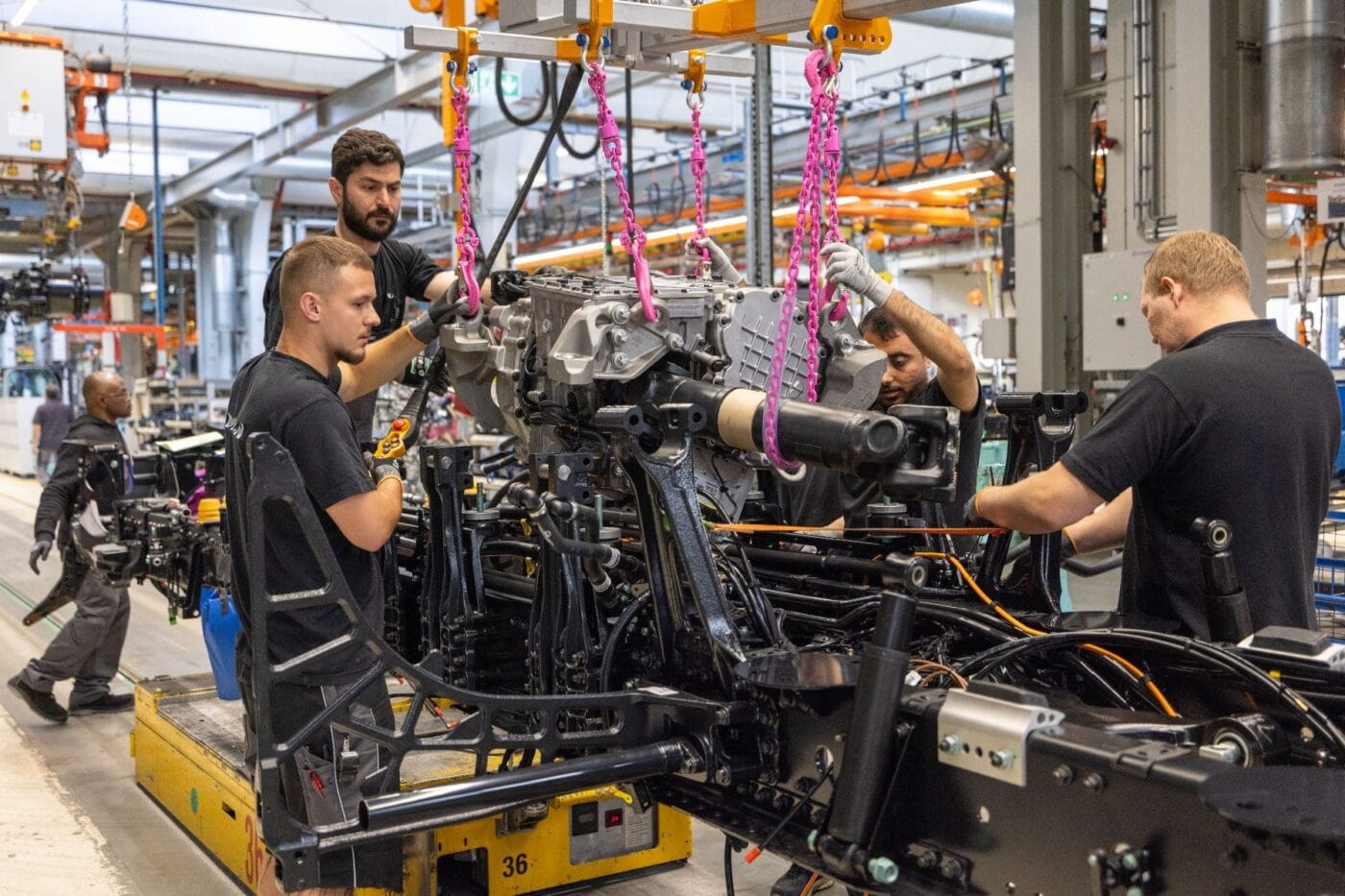

In order to kickstart series production of the eTruck, MAN has opted for a fully integrated mixed production of both electric and diesel trucks on the same assembly line – just like its competitors at Daimler Truck in Wörth. Michael Kobriger, board member for production and logistics has said this gives them a high degree of flexibility and responsiveness. “The production of electric or diesel trucks on a single line can be flexibly adapted to market developments, and the vehicles can be built exactly in the order in which they are ordered by customers. This innovative concept is accompanied by extensive changes along the assembly line as well as in the supply chain and logistics.”

For instance, while the diesel trucks initially receive axles, tanks and exhaust fixtures, the E-models instead receive two battery blocks under the cab together with the HV distributor, climate compressor and other electrical components – all installed compactly inside the E-Powerpack. This is prepared at a separate pre-assembly line.

MAN states that its maximum manufacturing capacity at the Munich plant is currently at approx. 100 trucks per day (diesel and electric), and that it takes around eight hours for each truck to be manufactured. The firm has said the major advantage of the eTruck is that all drive-relevant technology is arranged in the lower area of the frame: “The upper section thus remains completely free for the technical requirements of the body manufacturer and the customer has even more flexibility in the vehicle design.” Towards the end of the production line, all trucks undergo the ‘wedding’; an internal term used to describe the positioning of the cab on the fully assemble frame. Then, there’s the assembly of the tyres and the end-of-line ‘parameterisation’ and testing procedure.

To prepare for series production, MAN has trained over 5000 employees in the ‘high-voltage technology’ underpinning the power pack. Kobringer states that around €1bn euros will also be invested in the conversion of the company’s other European plants to electrification by 2030. With much of these plants being based in Germany, he argues it will boost the industrial economy of Bavaria – particularly Nuremburg and Munich. The battery packs for both MAN’s electric trucks and buses are currently installed in Nuremburg.

Regarding the eTruck, it will be launched in the models eTGX, eTGS and eTGL, all of which correspond to MAN’s existing diesel models. For example, the eTGX will share the wider cab of the diesel TGX. Each electric model, however, is based on the same modular platform. They each have a continuous output of 245 kW, 330 kW or 400 kW. Plus, with up to six NMC batteries, the trucks can provide a gross capacity of up to 534 kWh (480kWh usable). MAN states that this translates to up to 500 km of range without intermediate charging. Additionally, MAN has promised a seventh battery for even longer ranges of up to 740km – although the firm has not shared further details at this point.

At the opening ceremony, MAN claimed that day tours of up to 850km (with intermediate charging) and very low consumption of an average 97 kWh per 100km will be possible with the eTrucks. Incidentally, MAN considers its new electric truck to be particularly attractive for use in automotive logistics because it is already available as a so-called ultra-lowliner tractor unit.

What’s clear is that MAN is betting big on the eTruck, since electric trucks have so far played a minimal role at the company compared to electric buses. There is one exception to this, namely its first electric truck called the eTGM which entered production in 2018. With the company aiming to be carbon-neutral by 2050, as well as meet the current CO2 requirements of the EU, it plans to hand over more than 1000 eTrucks to customers this year alone.

Alexander Vlaskamp stated that it’s now up to politicians to help maintain momentum of electrified logistics in Europe. He said: “Politicians must now set the right course with regard to infrastructure expansion and CO2 pricing so that the ramp-up in e-mobility continues to gain momentum.”

0 Comments