DAF begins series production of XD and XF Electric trucks

The two electric models are based on the new generation of the XF and XD. These are two DAF series that have to date been purely combustion-engine models and are now joined by electric-powered offshoots. According to the Dutch manufacturer, the electric versions were considered from the outset during the development of the new generation of the DAF XD and XF. They are intended to take fully electric transport at DAF to a new level. The XD Electric and XF Electric are essentially the second and third electric models in the current portfolio – alongside the smaller XB Electric (available as 12-, 16- and 19-tonne models). The company’s debut electric vehicles, the three-axle CF Electric with up to 28 tonnes, built from 2018, and the two-axle LF Electric with up to 19 tonnes, are no longer available.

The manufacturer unveiled the two new XXL electric vehicles in 2022 at the IAA Transportation trade fair in Hanover. They have been available to order since then. At the opening of its own assembly plant for the XXL electric vehicles in Eindhoven in January 2023, DAF announced that series production would start in spring 2023. However, the start of production was delayed since then. The reason for the delay of almost two-and-a-half years is unknown. DAF does not address the delay in its press release on the start of series production. In 2024, the manufacturer only reported successful customer deployments of pre-series vehicles.

Drives from US parent company Paccar

But back to the present: DAF’s XD series is designed for the distribution segment, with larger windscreen and side windows for improved all-round visibility. The XF series is primarily a vehicle for distribution transport, but with maximum battery configuration, it can reach a long-distance transport level with a range of 500 kilometres. Both models feature modular powertrains with Paccar electric motors delivering between 170 and 350 kW, and a range of LFP battery packs offering ranges from 200 to over 500 kilometres, with charging of up to 325 kW.

As a Paccar subsidiary, DAF wants to leverage its strength in engine expertise above all else: depending on customer requirements, different electric drives from Paccar’s EX engine family are used in the vehicles. The Paccar EX-D1 drive is available with 170, 220 or 270 kW. The Paccar EX-D2 is available with 270, 310 or 350 kW. Both engines are combined with a three-speed gearbox from ZF. DAF increased the torque once again in the final development phase: whereas the D1 and D2 were originally designed for a maximum torque of 1,200 and 1,975 Nm, respectively, the data sheet now lists 1,500 and 2,400 Nm. The maximum regenerative braking power is 270 kW (D1) and 350 kW (D2).

In terms of technical design, according to DAF, the drive units are extremely compact and consist of two separate electric motors and the aforementioned centrally integrated three-speed gearbox. “Planetary gear sets ensure that the correct gear ratio is selected at all times and that when used under partial load, if possible, only one of the two electric motors is activated for maximum efficiency,” explained the Dutch manufacturer. As soon as more power and/or torque is required (“for example during acceleration, driving in hilly terrain, or during regenerative braking”), the second part of the drive unit kicks in. DAF describes the solution with two planetary gear sets as “significantly lighter than a conventional transmission,” which in turn benefits the truck’s payload. However, DAF does not specify the payload.

Two options: up to 29 or up to 50 tonnes

The Paccar EX-D1 drive unit is used in the XD Electric specifically for solo operation with a gross vehicle weight of up to 29 tonnes. The D2 is designed for more demanding applications and is suitable for gross combination weights of up to 50 tonnes, according to the company. It is the standard drive in the XF Electric.

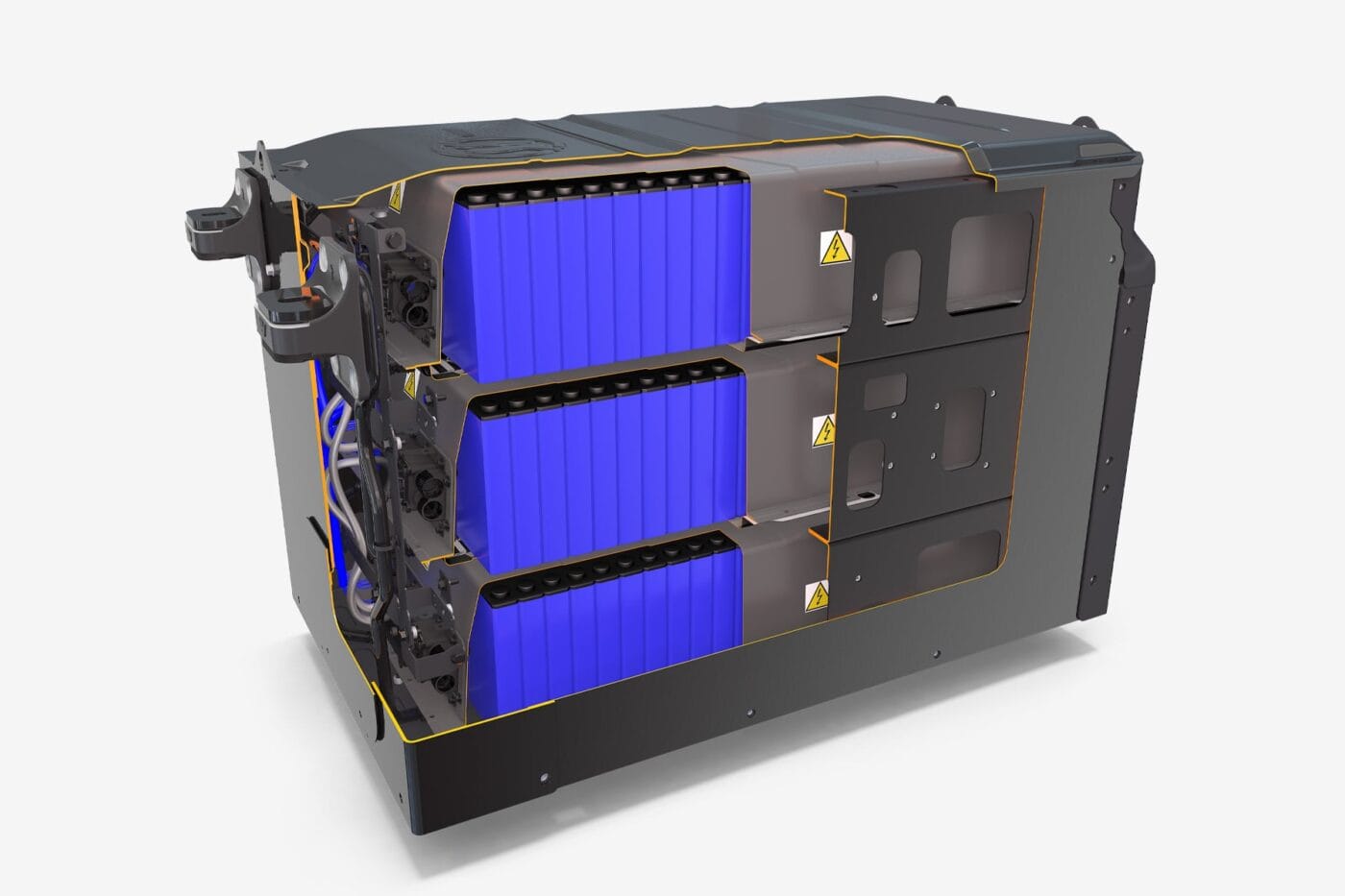

The battery with LFP chemistry can also be adjusted in stages. The smallest configuration consists of two battery packs with a total energy content of 210 kWh (for a range of approximately 200 kilometres). The largest option consists of five packs with a total of 525 kWh for a range of up to 500 kilometres.

The ordering options are as follows:

| Vehicle | Drive | Power | Torque | Number of battery packs | Gross battery pack capacity |

|---|---|---|---|---|---|

| XD Electric | PACCAR EX-D1 | 170 kW | 1,500 Nm | 2 to 5 | 210 to 525 kWh |

| XD Electric | PACCAR EX-D1 | 220 kW | 1,500 Nm | 3 to 5 | 315 to 525 kWh |

| XD Electric | PACCAR EX-D1 | 270 kW | 1,500 Nm | 3 to 5 | 315 to 525 kWh |

| XD Electric | PACCAR EX-D2 | 270 kW | 2,400 Nm | 3 to 5 | 315 to 525 kWh |

| XD Electric | PACCAR EX-D2 | 310 kW | 2,400 Nm | 4 to 5 | 420 or 525 kWh |

| XD Electric | PACCAR EX-D2 | 350 kW | 2,400 Nm | 4 to 5 | 420 or 525 kWh |

Source: DAF

DAF specifies a charging capacity of 325 kW for DC charging. An AC onboard charger is optional for both trucks and provides up to 22 kW of charging capacity with alternating current. DAF states that the charging window from 0 to 80 per cent battery charge takes around 45 minutes with three packs and around 2 hours with five packs when charging with 325 kW DC. The Dutch manufacturer has left open whether the electric trucks will also be equipped with an MCS charging port in the future. DAF also does not name the battery supplier in its announcement of series production. It merely refers to liquid-cooled LFP batteries, which are said to be very temperature-stable and come with an eight-year warranty from DAF.

| Vehicle | Drive | Power | Torque | Number of battery packs | Gross battery pack capacity |

|---|---|---|---|---|---|

| XF Electric | PACCAR EX-D2 | 270 kW | 2,400 Nm | 3 to 5 | 315 to 525 kWh |

| XF Electric | PACCAR EX-D2 | 310 kW | 2,400 Nm | 4 to 5 | 420 or 525 kWh |

| XF Electric | PACCAR EX-D2 | 350 kW | 2,400 Nm | 4 to 5 | 420 or 525 kWh |

Source: DAF

The company initially plans to launch the XD Electric and XF Electric as 4×2 tractor units and flatbed trucks. In addition, 6×2 trucks with steered front or rear axles (“for additional payload and improved manoeuvrability”) will be availablewith more configurations planned for 2026. DAF has not specified when the first deliveries are expected. However, it should not be long once series production begins.

Primarily designed for distribution transport

“Anyone who works with our new electric trucks will immediately recognise that these versions were an integral part of the development of the New Generation DAF XD and XF right from the beginning,” said Bart Bosmans, member of the board and responsible for marketing & sales. “The driveline and vehicle concept form a perfect combination, especially for the intensive distribution for which these new electric trucks are primarily designed.” In addition to the vehicles, DAF offers a service package that ranges from the provision of a charging ecosystem to driver training and route planning to the Paccar Connect fleet management platform.

In addition to the drive systems from parent company Paccar, DAF cites its battery management system and ‘extremely aerodynamic design’ as key strengths of its electric trucks. The cab features rounded corners and filled seams and gaps to ensure optimum airflow around the body. Side skirts, deflectors, collars, an aerodynamic floor panel and digital cameras instead of mirrors are also designed to reduce air resistance.

When it comes to superstructures, DAF promises the same options familiar from combustion engines. This is made possible by the flexible mounting of the battery packs on the chassis. “The placement of the packages can be perfectly tailored to the vehicle’s intended use, providing ample space for mounting of, for instance, a side loader body or crane legs,” the company writes. An ePTO (650 volts / 25 kW or 90 kW output) is also available as an option, for example, to drive an electric cooling system.

Recuperation adjustable up to one-pedal driving

The Dutch manufacturer cites an optional ‘curb view window’ and a folding passenger seat as further features of both electric trucks. This side-mounted window, in combination with the folded passenger seat, allows a direct view of pedestrians and cyclists to the right of the truck. Also new is the one-pedal driving function, which is adjusted on the steering column lever for recuperation. The desired braking power can be set in increments of 33, 66 or 100 per cent. Also on board: a range of driver assistance systems such as the DAF Digital Vision System, City Side & Turn Assist and Corner View. The cab is available as a Day Cab, Sleeper Cab and Sleeper High Cab. This is also the case for the XF, which was previously only available with a Sleeper High Cab.

A Bolt & Play package is also available for the DAF XD 6×2 with steered trailing axle, which is specially designed for mounting a side-loading refuse collection body. “In this case, the chassis is fitted ex-works with an e-PTO, specific mounting brackets for the structure and connectors that control the structure’s functions,” writes DAF.

Externally, the electric models differ from the combustion engines in a number of deliberate ways, most notably with blue highlights on the radiator grille and headlights. The cockpit also features a digital instrument panel “specifically developed to provide an at-a-glance overview of the electric driveline, including energy consumption, charging status, operating range, power output and regeneration,” according to DAF. The optionally available truck navigation system also displays charging locations.

Electric trucks made in Eindhoven

The two electric trucks will be built in Eindhoven. According to earlier statements by DAF, the construction of the corresponding hall and the installation of the machines was completed in 18 months. However, the assembly plant, which will open in early 2023, is not a completely new facility, but merely a special assembly line for electric models, which is located on the existing factory premises in Eindhoven in a different hall than the assembly line for combustion engine trucks.

The production of electric trucks in Eindhoven begins with a frame manufactured in another part of the plant without a powertrain, but with the cab already assembled. The 4×2 and 6×2 tractors and chassis are then completed in an eight-step process on the electric truck assembly line with all the necessary components to become the XD Electric or XF Electric. In addition to the vehicle assembly line, there is another assembly line in the new hall: the battery packs are assembled on the sub-assembly line, while all high-voltage components, including batteries and powertrain, are mounted on the chassis on the main assembly line.

This article was first published by Cora Werwitzke for electrive’s German edition.

0 Comments