Project E|MPOWER launches test phase for highway charging in Germany

The test track along the A6 motorway in the Upper Palatinate was inaugurated in the summer. The section between Amberg-West and Sulzbach-Rosenberg is just under one kilometre long. With the official completion of the construction phase, the project, led by Friedrich-Alexander University Erlangen-Nuremberg (FAU), is taking “a decisive step towards electrified mobility,” according to the FAU.

However, it is not only the test phase that is now beginning that is expected to yield important insights into inductive charging while driving: the consortium consisting of FAU, Electreon, VIA IMC, Risomat and the Georg Simon Ohm University of Applied Sciences in Nuremberg (Ohm), as well as the partners Seamless and Eurovia involved in the project, intend to use the results of the construction phase to develop construction and installation processes suitable for series production. The efficient production of induction coils is also part of E|MPOWER.

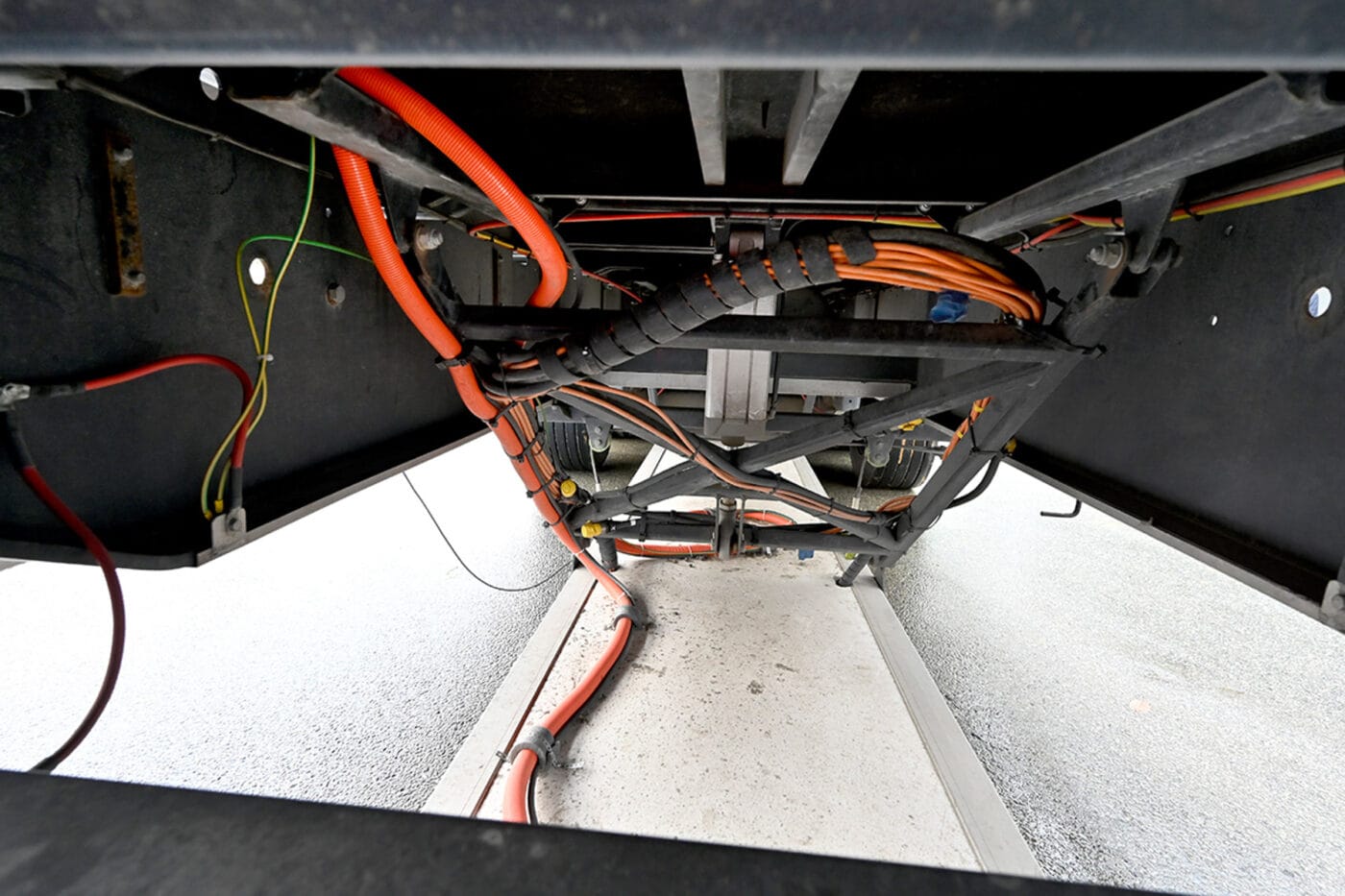

The system embedded in the A6 is based on a solution from Electreon, one of the market leaders in inductive charging and, above all, dynamic inductive charging. The principle sounds simple: coils embedded in the road surface generate a magnetic field as soon as a suitably equipped vehicle drives over them. A counter coil in the vehicle absorbs the energy and feeds it directly into the battery. Unlike overhead line solutions, for example, the technology is invisible and vandal-proof, integrated into the road surface, so that the section remains a normal stretch of motorway for all other road users.

The technology for the integration and scalable production of the coils comes from Seamless Energy Technologies in Nuremberg. “The company supplies the electronic unit, which is integrated beneath the road surface and enables precise energy transfer between the road and the vehicle,” as FAU writes. “The system works dynamically while driving as well as statically when parked.” The press release does not specify the charging capacities to be transmitted. The press photos from the event do not provide any information on this: the display always shows ‘- – kW’. A recently installed Electreon system near Paris is said to be capable of transmitting up to 200 kW of continuous power and 300 kW of peak power.

The use of Electreon technology on the A6 is the longest test track of its kind in Germany to date – and, as mentioned, the first test on/in a motorway. However, it is not the first use in Germany: Electreon already implemented its first projects in Karlsruhe and Balingen in 2020 and 2023, although the latter involved a slow-moving shuttle bus for a garden show. The motorway section near Amberg is longer and the vehicles are travelling at significantly higher speeds. E|MPOWER also focuses on production and construction techniques in order to reduce the construction costs and duration for such systems.

‘With E|MPOWER, we are literally bringing research to the road,’ says Florian Risch, Professor of Assembly Technologies for Electrical Energy Storage at the Chair of Manufacturing Automation and Production Systems (FAPS) at FAU. ‘The technology has the potential to overcome range anxiety, reduce the need for battery imports and strengthen regional value creation in electromobility.’

Andreas Wendt, Managing Director of Electreon in Germany, adds: ‘The test track on the A6 is an important step in validating our technology under real-world conditions and demonstrating its advantages for everyday use. We are convinced that inductive charging will make a decisive contribution to making electric mobility more efficient and suitable for mass use.’

One potential advantage of inductive charging is that the system with the counter coil on the underbody of the vehicle can be used on different types of vehicles – cars, lorries or buses. Overhead lines, on the other hand, have to be mounted high enough on the motorway so that lorries and coaches can pass underneath them, which means that the overhead line is very high for cars. An electric truck, an electric van and an electric car – a Toyota bZ4X – will be on the road during the test.

Electreon states that energy flow can be intelligently controlled via a digital platform. ‘Charging times and quantities are adjusted according to demand in order to avoid peak loads and use the available energy efficiently. In this way, the system supports optimised fleet management and contributes to the stability of the power grid,’ the announcement states.

The E|MPOWER project is funded by the German Federal Ministry for Economic Affairs and Climate Protection (BMWK) as part of the Elektro-Mobil programme and supported by the federal motorway company Autobahn GmbH. The project consortium used the resurfacing of the Nuremberg-bound carriageway of the A6 motorway between the Sulzbach-Rosenberg and Amberg-West junctions to implement the test track on a section of the motorway. In the long term, the technology is to be extended to longer sections of motorway and urban areas.

fau.de (in German)

This article was first published by Sebastian Schaal for electrive’s German edition.

0 Comments