Dongfeng tests solid-state batteries in extreme cold conditions

These prototypes, which appear to be based on the Dongfeng 007, are reportedly equipped with solid-state batteries boasting an energy density of 350 Wh/kg, according to Chinese reports. This battery variant is said to be very close to series production: Dongfeng aims to begin mass-producing solid-state batteries with this energy density by September 2026. However, the first series application is as reported, not planned for the Dongfeng brand but for Voyah. Nevertheless, in February 2025, the figure mentioned was still 300 Wh/kg.

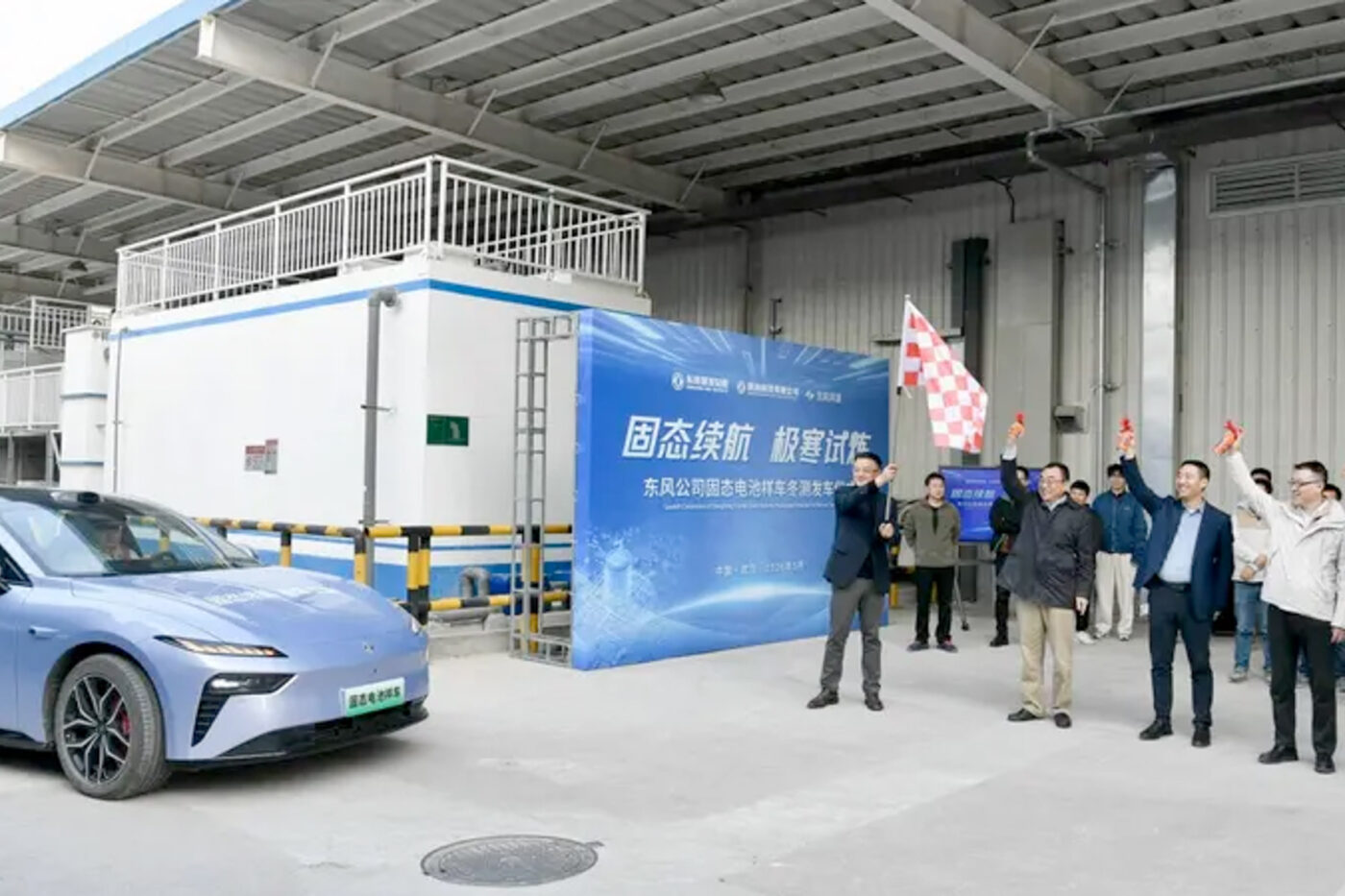

The new prototypes left Dongfeng’s headquarters in Wuhan, in the central Chinese province of Hubei, earlier this week and have since been travelling north. The tests are set to take place in Mohe, Heilongjiang Province, in north-eastern China. According to Dongfeng, these cold-weather tests represent a “decisive step towards the industrial application of the company’s solid-state battery technology.”

The new cells, with an energy density of 350 Wh/kg, were manufactured on Dongfeng’s pilot production line. Cells at this technological stage have already passed several validation steps relating to materials and the overall electrochemical system. The winter test now serves as a further, critical validation phase ahead of production. The cells must demonstrate their expected performance not only in the laboratory but also in vehicles under real-world conditions, such as snow and ice on the roads, as well as fluctuating temperatures. The tests are intended to provide insights into battery performance.

Winter tests to validate laboratory results

Reports indicate that over 70 tests under extreme cold conditions, ranging from -40 to -30 degrees Celsius, are planned to systematically evaluate the battery’s performance metrics. These will assess aspects such as range stability in winter, charge/discharge efficiency, structural safety, and integration capability within the vehicle. The tests are also expected to validate the laboratory results in a real-world setting: according to Dongfeng, the battery retained up to 72% of its energy at -30 degrees Celsius. Additionally, it passed safety tests in a thermal chamber at 170 degrees Celsius.

Dongfeng has so far refrained from providing further technical details about the new solid-state cells. At present, it is only stated that the battery is designed to offer high safety, cold resistance, and a range of over 1,000 kilometres. This range, most likely determined under the Chinese CLTC test cycle, is primarily achieved through the aforementioned energy density of 350 Wh/kg at the cell level. For comparison, current LFP cells are listed by the portal CN EV Post as having 140–210 Wh/kg, while NMC cells range from 200–260 Wh/kg. CLTC ranges of 800 kilometres are no longer uncommon in current models. The higher energy density of the new solid-state cells could therefore enable a battery pack of identical dimensions to current NMC or LFP batteries to store sufficient energy for significantly exceeding 1,000 kilometres in the standard test. Depending on the extent of the cold resistance claimed by Dongfeng, the battery could even achieve this in winter conditions.

Although the 350 Wh/kg battery is set to debut in a Voyah production model, it is in fact just one variant of the modular system Dongfeng is developing. The company has stated to Chinese media that its portfolio will include “several products with energy densities ranging from 240 Wh/kg to 500 Wh/kg.”

The portal CarNewsChina references a report by the Chinese newspaper Hubei Daily, which states that Dongfeng’s solid-state batteries utilise “high-capacity ternary cathodes, silicon-carbon anodes, and oxide-polymer composite solid-electrolyte systems.” In China, the term “ternary cathodes” typically refers to NMC cathodes, which incorporate lithium, nickel, manganese, and cobalt. However, NCA cells (nickel-cobalt-aluminium oxide) also fall under this designation. This configuration of solid-state cells is intended to address “the safety and low-temperature weaknesses of conventional lithium batteries.”

At the CES in Las Vegas, the Finnish technology company Donut Lab recently drew attention with an allegedly production-ready solid-state battery boasting an energy density of 400 Wh/kg, which is set to be integrated into electric motorcycles by Verge Motorcycles, Donut’s parent company, later this year. However, the company itself has not provided further details about the technology or planned production. Investigations by several battery-focused YouTubers suggest that the core technology may not consist of conventional battery cells but rather capacitors.

0 Comments