General Motors & VAC to build magnet plant in the USA

General Motors is cooperating with the German company Vacuumschmelze (VAC), which specialises in magnetic materials, to build a factory in the USA. Permanent magnets for the electric motors of the Ultium platform are to be built there. GM has entered into a second partnership in this field with the US company MP Materials.

++ This article has been updated. Kindly continue reading below. ++

First of all, the deal with Vacuumschmelze: So far, both sides have agreed on the cooperation in a non-binding letter of intent. However, VAC and GM expect the negotiations to lead to a final agreement in early 2022. The main focus of the German-American duo is the construction of a VAC production plant, which is to start production in 2024 and create hundreds of jobs. The exact location in the US is to be announced at a later date.

What is clear, however, is that magnets produced at the plant in the future will go to GM’s various electric motor production sites in the US. “As VAC’s Permanent Magnet Division is the only industrial scale producer of rare earth permanent magnets in the Western Hemisphere, VAC brings reliable scale and experience to GM’s supply chain,” said Erik Eschen, CEO of VAC. “We are thrilled to join forces with GM on this journey into an increasingly electrified world, leveraging sustainable clean energy solutions.” The German company claims to have mastered the entire process for manufacturing permanent magnets, from basic development to the production of end products.

In parallel, General Motors has entered into another cooperation in this context with MP Materials: The US company is to supply rare-earth materials, alloys and finished magnets procured and manufactured in the US for GM’s electric motors. In contrast to the cooperation with VAC, however, the focus is likely to be more on the primary products, because MP Materials owns and operates the Mountain Pass rare earth mine and processing plant in California – according to its own information, the only active and scaled production facility for rare earths in America.

Rare-earth metals sourced from Mountain Pass will be processed into metal, alloys and magnets at a new company production facility in Fort Worth, Texas. GM wants to purchase these products and has already signed a binding agreement with MP Materials to do so. A final supply agreement is to follow “shortly”. Production in Fort Worth is to be ramped up gradually from 2023.

GM and MP Materials do not intend to limit their strategic cooperation to supply agreements. They are working together to “accelerate the restoration of the US rare earth supply chain to commercial scale with high resilience and environmental sustainability”. In this respect, the cooperation also takes on a political dimension. The administration of US President Joe Biden is known to have initiated the stabilisation of certain key sectors of the US auto industry following a review of US supply chains.

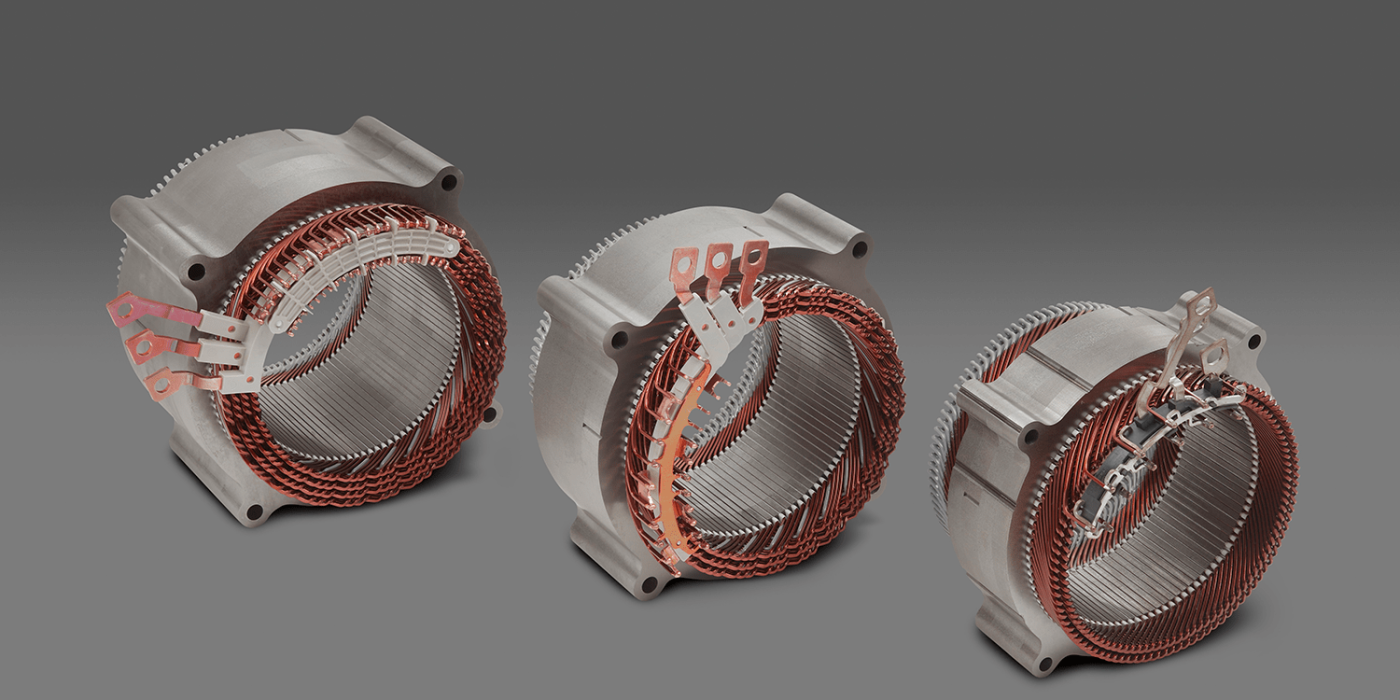

Rare earths are, among other things, essential for magnets, which in turn are at the heart of electric motors. In these, an electric coil creates a magnetic field that acts against strong magnets to generate the torque that drives the vehicle’s wheels.

“We are building a resilient and sustainable EV manufacturing value chain in North America, from raw materials to cell manufacturing to electric drive motors and beyond, further accelerating GM’s vision to support a mass market for EVs,” expressed Shilpan Amin, GM Vice President, Global Purchasing and Supply Chain. “Our work with MP Materials is another bold step forward that will help ensure that we meet our goal to lead the EV industry in North America in more than just sales.”

Update 22 April 2022

Following General Motors’ agreement with US company MP Materials in December 2021 to supply rare earth materials, alloys and finished magnets for its electric motors, things are now getting concrete: MP Materials is starting to build its first corresponding manufacturing facility in Fort Worth, Texas, and has signed a final supply agreement with GM. The MP Materials facility in Fort Worth will have the capacity to produce about 1,000 tonnes of neodymium-iron-boron magnets per year from the end of 2023, enabling the production of about 500,000 electric car traction motors.

gm.com, vacuumschmelze.com (GM/VAC), gm.com, mpmaterials.com (GM/MP), mpmaterials.com (update)

0 Comments