Renault launches final testing phase of the Renault 5

As part of an extensive development programme, nine prototypes of the electric Renault 5 are currently undergoing final endurance tests. The platform, powertrain and battery of the test vehicles are already up to series standard. Now Renault also published the first background information on the new CMF-BEV platform.

Visually, the prototypes, which are currently being tested on ice and snow in Arvidsjaur Sweden, and in the Renault technical centres of Lardy near Paris and Aubevoye in Normandy, still have little in common with the Renault 5, which has so far only been shown as a concept. In fact, they are bodies of the Renault Clio, which runs on a small combustion engine car based on the CMF-B platform.

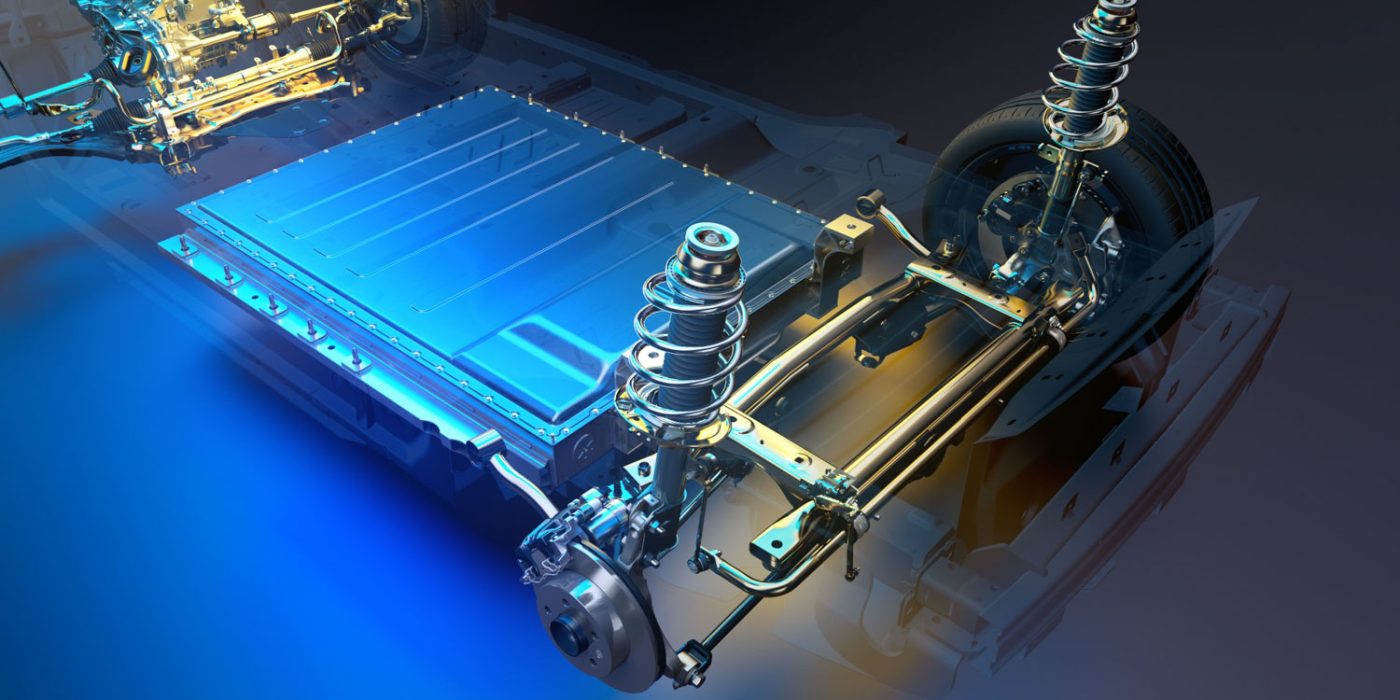

The fact that this is possible without major problems is also due to the relationship between the two platforms: Although Renault calls the CMF-BEV its own platform for small electric cars in the B segment, it is based on the combustion engine platform of the “Common Module Family” (CMF) for the B segment – the CMF-B, in other words. In concrete terms, 70 per cent of the components are to be identical, for example in the chassis or the assistance systems and infotainment. This is primarily intended to reduce costs.

Because that was precisely one of the main goals in the development: the production of the Renault 5 should be 30 per cent cheaper than that of a Zoe. Due to the close relationship between the two platforms, production on a common line is also possible, so the Renault 5 can come off the production line together with the Clio and Captur. This also reduces costs.

All advantages of an EV platform despite being based on a combustion vehicle?

Nevertheless, the CMF BEV should offer “all the advantages of an electric platform”, as Gilles Godinot, Chief Engineer for the new CMF BEV, explains. In other words, a long wheelbase and short overhangs not only increase the installation space for the battery, but also offer the occupants more room inside. And incidentally, this also corresponds to the proportions of the classic Renault 5. Since the platform allows for different wheelbases and track widths, further models with deviating dimensions can be developed relatively flexibly on the basis of the CMF-BEV. “The platform allows us to have good battery integration,” says Godinot. “When we connect the battery housing to the frame, it improves the structure and the NVH behaviour, so it reduces device development and vibrations. At the same time, the surrounding body protects the battery.”

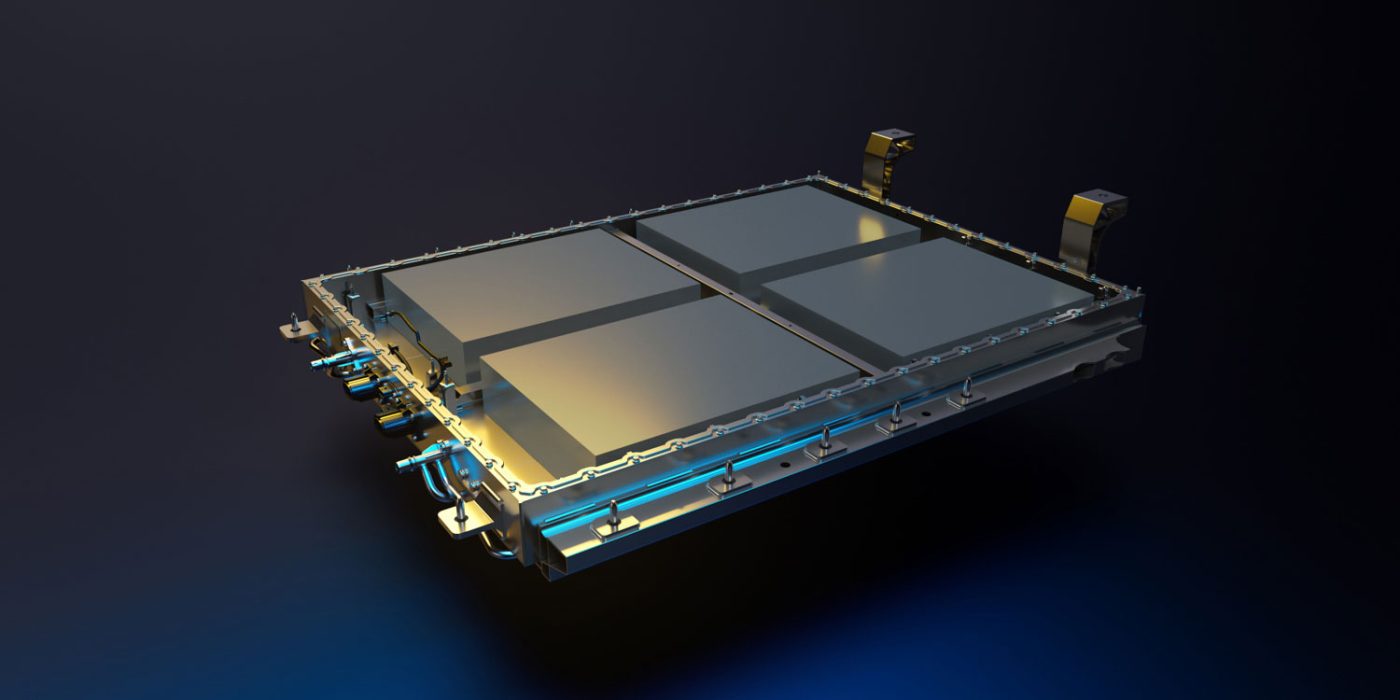

Nevertheless, since it is not just the CMF-B with a battery in the underbody instead of the exhaust system, Godinot’s team was able to make another important decision to reduce costs: instead of using every cubic centimetre of the available installation space with an angled battery housing, it was possible to develop a very simple, because simply cuboid-shaped battery housing. “With this form factor, we reduce complex shapes in the battery pack, which makes production simpler and reduces costs,” explains Eric Blanchard, Director of Zero Emission Projects at Renault. “At the same time, we have reduced the number of components.” This alone should save 15 kilograms compared to a Zoe battery.

Although Renault does not use cell-to-pack technology to increase the energy density in the small car battery, the Renault 5 will only have four large modules in the housing. Again, this reduces the number of components and pays for simpler production. At the moment, however, the French company is not giving any precise details about the modules and the cells that will be installed in them. This leaves open the question of how large the battery will be and what range it might be able to achieve. Even the question of whether the Renault 5 will be available with one or more battery options has not yet been answered by the development team. What is clear, however, is that the cells will come from Envision AESC, which is building its own cell factory in Renault’s eMobility cluster ElectriCity in Douai.

However, Delphine De Andria, head of product development in the B-EV segment, gave a target figure that is also likely to have an impact on the battery on offer. “It is far too early to give final prices. But it is our goal that the price will be below all main competitors, definitely below the Zoe,” she said. She left open which main competitors she was referring to.

Renault 5 unlikely to receive LFP battery

A likely candidate is the ID.2, which Volkswagen presented a few weeks ago as a near-production concept. The Wolfsburg-based company quoted an entry price of “less than 25,000 euros”, but remained silent on detailed questions about this basic model. However, the range of 450 kilometres also quoted for the ID.2 refers to a presumably 60 kWh NMC battery, while the base model should manage with a cheaper battery of around 40 kWh – presumably with an LFP cell chemistry.

However, the French company had already publicly ruled out an LFP battery for the Renault 5 in 2021. What exactly the NMC battery will look like remains to be seen. This also applies to the charging power that the developers are targeting for the Renault 5. When asked by electrive.net about the importance of fast charging in light of VW’s announcement of a 20-minute charge time from ten to 80 per cent, Blanchard replied: “Fast charging is very important for customers in the B-segment, so it is also a focus topic for us.” However, Jean-Sébastien Blazy, Vice President of Vehicle Performance, added: “We have a lot of Zoe on the road, so we know the needs of customers in the segment. Of course, you can say that faster is better. But if you don’t use it regularly, you have to ask yourself if you need to pay for that functionality.” In other words: the Renault 5 will probably not quite reach the (mathematically necessary) 120 kW charging power of the ID.2, at least not in the cost-optimised base model – but it will probably be more than the 37 kW peak power of the Renault Zoe.

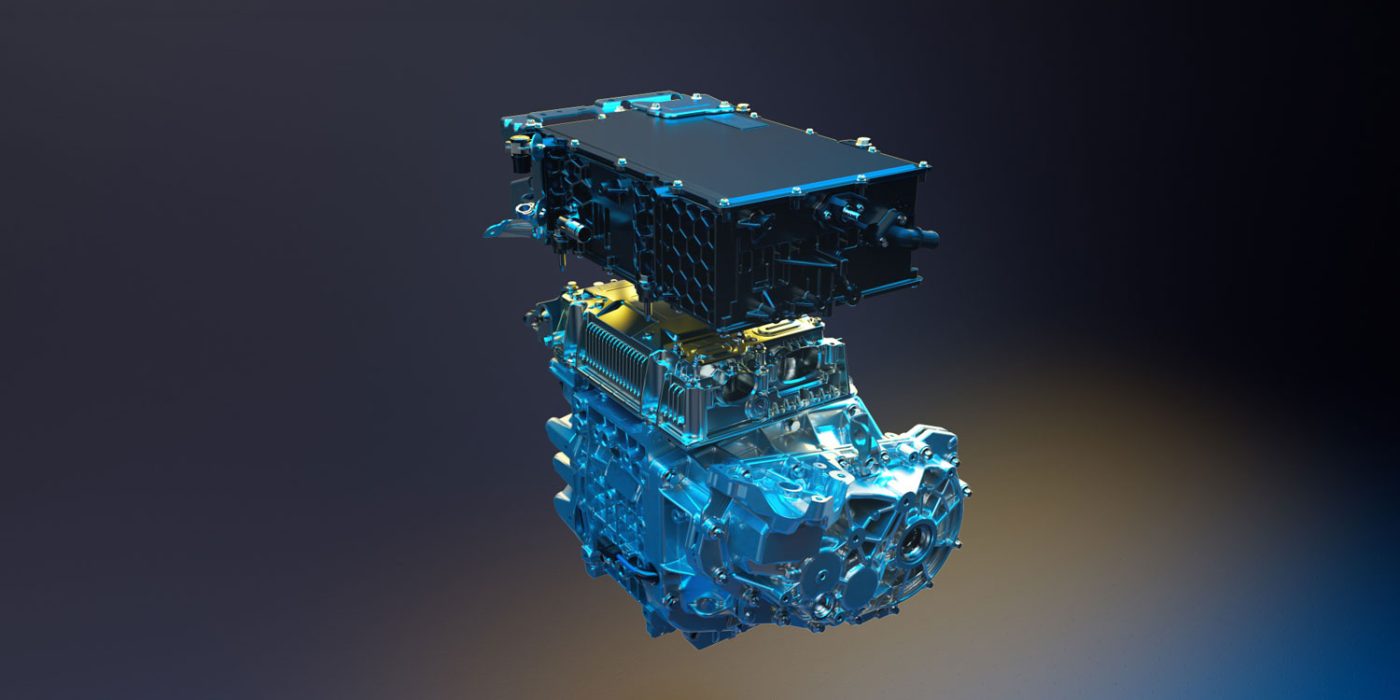

Renault also did not go into detail about the Renault 5’s powertrain in the media round, the exact figures will only be available at the presentation of the production version. According to Blanchard, the electric drive will be “rightsized”. The performance will probably be roughly on par with the Mégane E-Tech Electric, but the costs will be lowered for the B-segment drive. Whether the Renault 5 will have a peak output of up to 160 kW, as in the Mégane, will of course also depend on the battery. One thing is clear, however: Renault will do without permanent magnets and thus rare earth metals in the separately excited synchronous drive.

Incidentally, another component is placed above the drive system installed on the front axle, which should further contribute to space and cost savings: The power electronics, the battery management, the onboard charger and the DC/DC converter for the 12-volt system are integrated into one housing.

Despite all the cost optimisations, the French company left out one potential saving: the chassis. Since driving pleasure was also an important point in the developers’ specifications, the Renault 5 will be one of the first models in this segment to have an elaborate multi-link rear suspension. In combination with the low centre of gravity thanks to the battery, the Renault 5 should “set standards for dynamics and driving pleasure in its segment”.

With reporting by Sebastian Schaal, Germany.

0 Comments