ZF orders semiconductors from STMicroelectronics

German supplier ZF says it has signed a long-term contract to supply silicon carbide semiconductors. ZF intends to use the semiconductors to serve customer orders in electromobility from 2025.

Specifically, ST’s silicon carbide modules will be integrated into ZF’s inverter platform, which the supplier says will go into series production in 2025. ZF emphasises that in ST it has found a supplier “who can produce silicon carbide modules of exceptionally high quality and in the required quantities”. This is because, according to the statement, the contract, which is set to run for several years, provides for ST to supply a double-digit million number of silicon carbide modules.

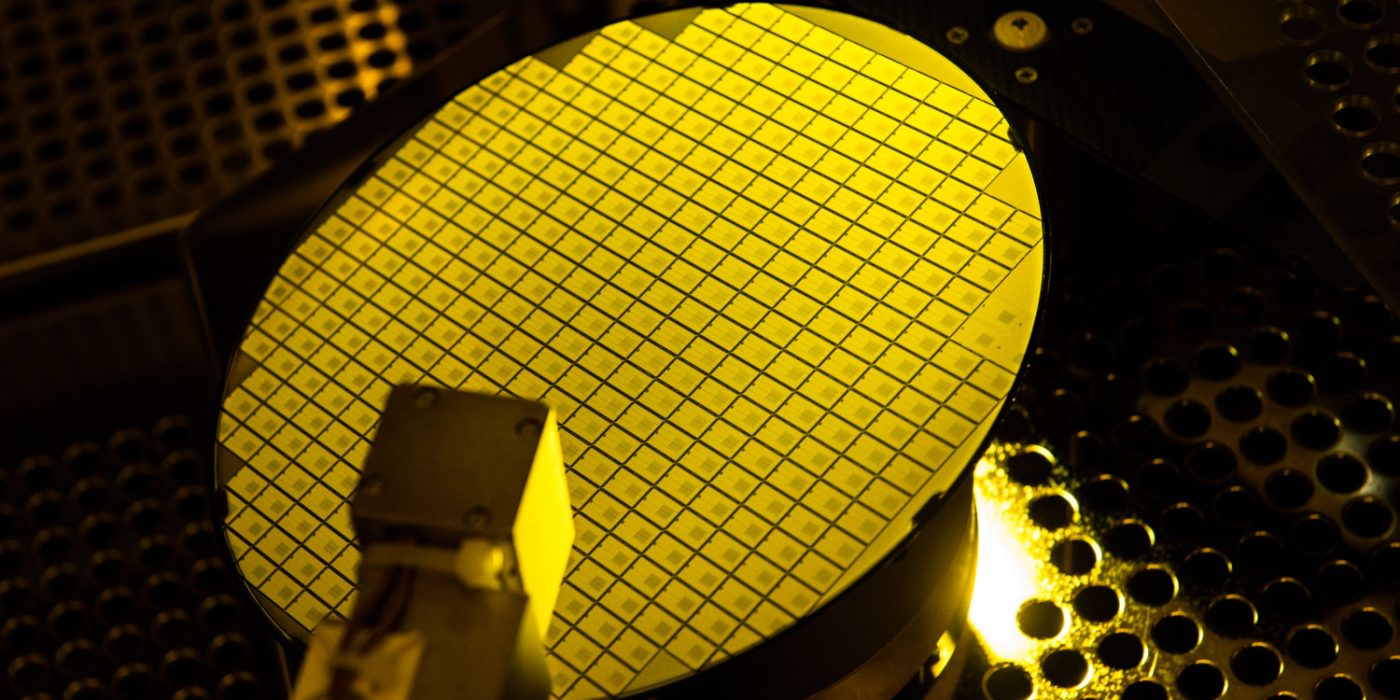

ST will manufacture the silicon carbide chips in production facilities in Italy and Singapore, and package the chips into modules called STPAK and test them in Morocco and China. Third-generation silicon carbide MOSFET modules will then be supplied to ZF from 2025 onwards. According to ZF, it will then be able to connect a variable number of these components together in order to adapt the inverters to customers’ performance requirements without changing the design of the inverter.

Among others, these inverters are installed in vehicles of an unspecified European car manufacturer. The model in question is also to be built in series from 2025. The advantages of SiC semiconductors in electric car inverters (or also inverters for wind turbines and PV systems) are well known: Silicon carbide devices reduce power losses, have higher efficiency, higher power density and higher reliability. At the same time, they enable smaller and more cost-effective system designs. An electric car can thus charge faster, drive further and offer more space. However, SiC semiconductors are significantly more expensive than those made of pure silicon, which is why they are more likely to be found in premium vehicles.

The supply agreement now concluded with STMicroelectronics is the second SiC deal for ZF within a short time. As is well known, ZF is building its own factory for SiC semiconductors in Saarland together with the American SiC specialist Wolfspeed.

“With this strategically important step, we are strengthening our supply chain to be able to securely supply our customers. Our order book in electromobility until 2030 now amounts to more than 30 billion euros. For this volume, we need several reliable suppliers for silicon carbide devices,” says Stephan von Schuckmann, member of the ZF Board of Management responsible for electromobility as well as materials management. “In STMicroelectronics, we now have a supplier whose experience with complex systems meets our requirements and who, above all, can produce the devices in exceptionally high quality and at the required quantities.”

Marco Monti, ST board member responsible for the automotive division, adds: “The key to success in electric vehicle technology is greater scalability and modularity with increased efficiency, peak power and affordability. Our silicon carbide technologies help deliver these benefits and we are proud to work with ZF, a leading automotive supplier for electrification, to help them differentiate and optimize the performance of their inverters.”

0 Comments