BMW prepares Regensburg plant for making the iX2 EV

BMW will produce a second electric model at its factory in Regensburg this year. The fully electric iX2 will follow the iX1 that has been coming off the lines in Regensburg since autumn 2022.

By late 2023, BMW plans to hire around 500 new employees at the site and invest more than 350 million euros in vehicle production. The statement does not precisely summarise the production areas in which the investments will flow. What is clear, however, is that BMW will prepare the plant for an increasing number of battery-electric cars.

After all, in Q1 2023, every fifth car produced in Regensburg was a BEV, i.e. an iX1. And that’s just a few weeks after series production started in mid-November. BMW reportedly targets that by 2024 at least every third BMW from one of the plants in Bavaria should be electric. With today’s 20 per cent share of electric vehicles, Regensburg could manage the increase to 33 per cent even with the rising demand for the iX1 alone – with the iX2 as the second BEV model; the probability increases even further.

Technical data on the iX2 remain unknown. The powertrain will probably not differ significantly from the iX1. The latter uses a 64.7 kWh battery and an electric all-wheel drive with 200 kW system power (230 kW in boost). The range of the compact SUV is between 413 and 438 kilometres, depending on the trim. The somewhat more streamlined SUV coupé should have a slightly higher range, but WLTP values for this model are not yet available.

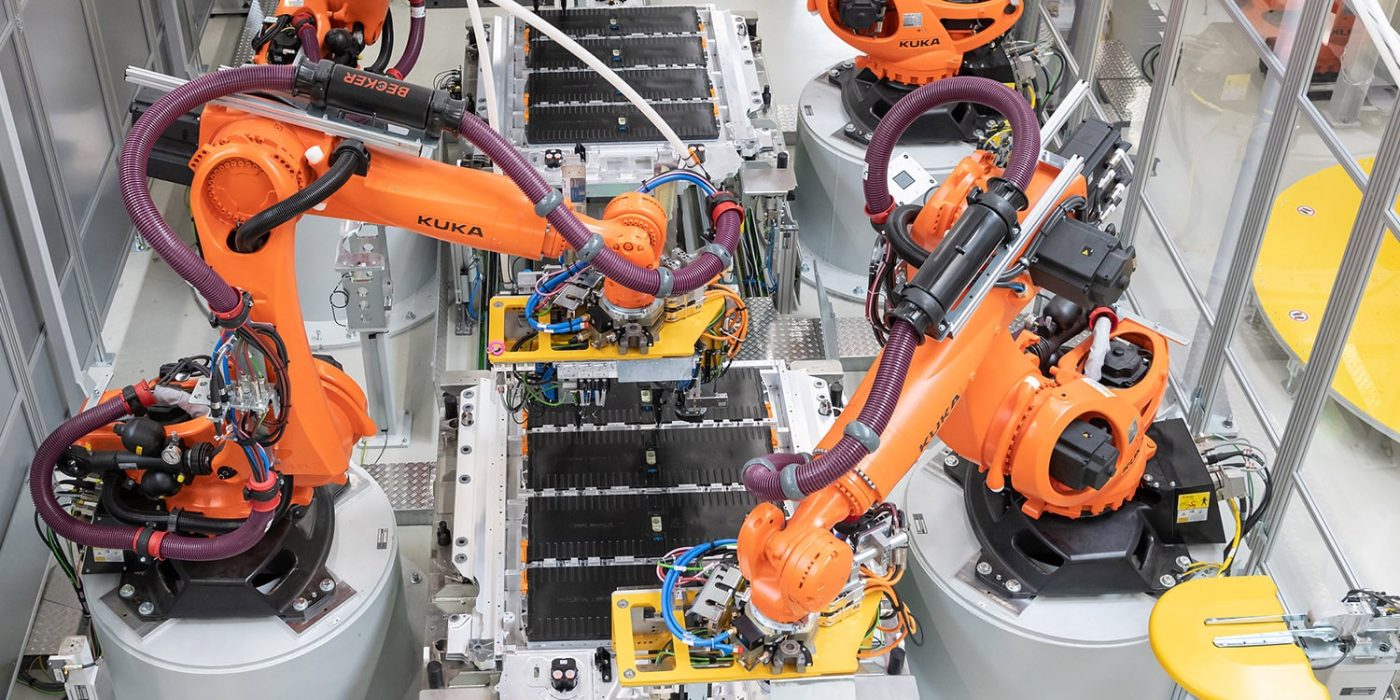

Back to Regensburg: the high-voltage batteries for the electric cars are also assembled near the plant. The EV component factory (plant 6.11) in Leibnizstraße covers a production area of around 45,000 square metres. Since commissioning in the autumn of 2022, around 30,000 high-voltage batteries for Regensburg’s vehicle production have been assembled there.

The plant had already started painting battery cells in April 2021. In the process, the aluminium housings of the prismatic cells are coated with a thick varnish, which, according to BMW, increases the mechanical robustness and thermal conductivity of the battery cell. By the end of 2021, painting was expanded from one to four lines, and in October 2022, assembly of the high-voltage batteries also began.

“The close connection of component production to vehicle production is part of our strategy. Within less than two years, we have completely converted our component plant in Leibnizstrasse for electromobility,” says Markus Fallböhmer, Head of Battery Production at the BMW Group.

With reporting by Sebastian Schaal, Germany.

bmwgroup.com (in German)

0 Comments