Magna starts eDecoupler production for German OEM

Automotive supplier Magna has started production of a first-to-market modular eDecoupling unit for several battery-electric vehicles from a German premium OEM – likely to be Mercedes.

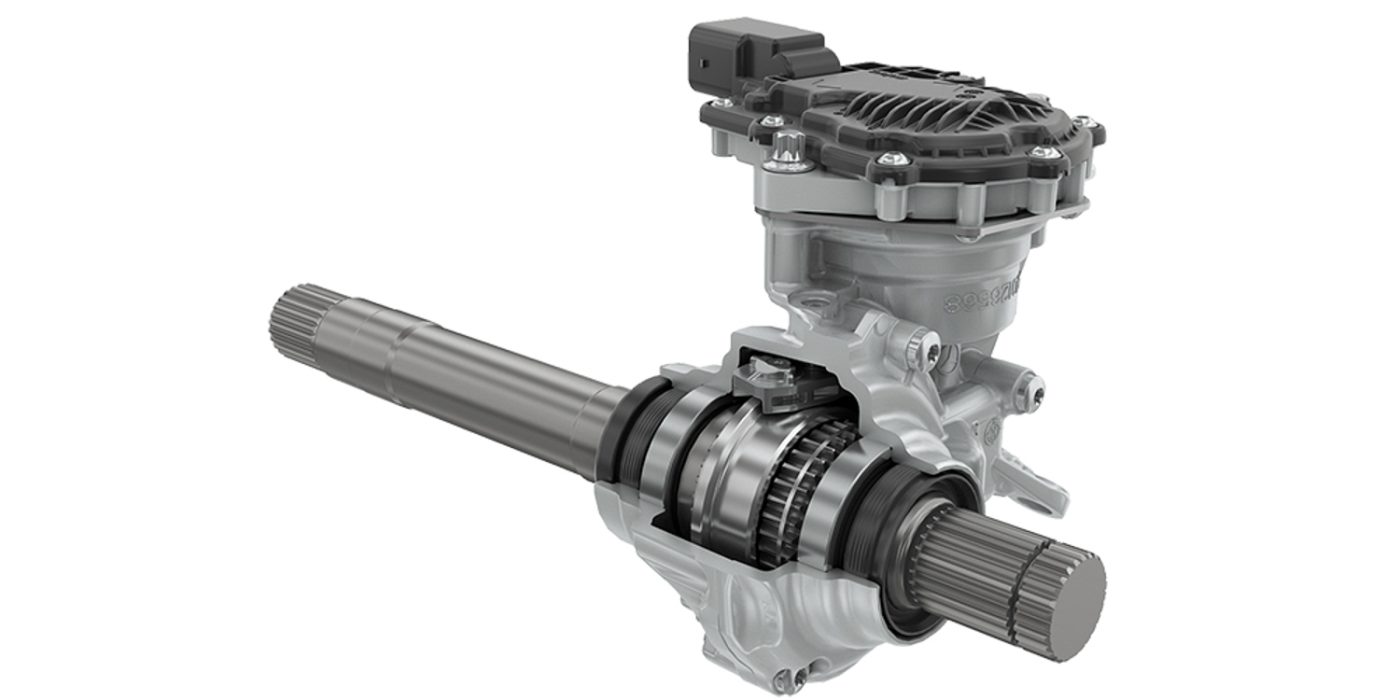

Magna’s electromagnetic eDecoupling is integrated into BEVs as a complete module and disconnects the e-motor from the drive shaft when no motive power is needed. This reduces energy consumption and thus increases efficiency. According to Magna, the unit helps to increase the electric range by up to nine per cent.

In the announcement of the Canadian supplier, the name of the customer is not mentioned – as is usual for the majority of suppliers. In terms of the concept alone, two customers would come into question, the VW Group for the PPE of Audi and Porsche or Mercedes-Benz: Such a decoupling unit is needed above all in permanently excited synchronous motors (PSM), since the permanent magnets placed in the rotor generate a rotating magnetic field, which leads to a voltage in the magnetic coils of the stator – in this way, energy is recovered during deceleration by means of recuperation. Especially in all-wheel drive electric cars with a second electric motor on the front axle, however, recuperation is not desirable if the vehicle is only driven by the electric motor on the rear axle at that time – then the PSM on the front axle would work against the rear drive unit.

In the Taycan, Porsche therefore relies on a so-called “zero torque control” for the front PSM, in which the front PSM is energised to such an extent that its recuperation effect is neutralised. Hyundai also uses a mechanical clutch on the front PSM in its E-GMP models. With other motor concepts, such as an asynchronous machine or a separately excited synchronous machine, this effect does not occur at all, so an eDecoupling unit is not necessary.

Theoretically, a PSM on the rear axle could also be mechanically decoupled if the vehicle is to sail – but the savings effect is higher on all-wheel-drive models on the front axle.

For this reason, BMW is also ruled out as a potential customer; the Munich-based company relies on externally excited synchronous machines for its current generation of drives. Mercedes is already producing the EQS and EQE with PSM on the front axle, so the start of production at Magna would be too late. However, Magna would be very early for the production start-ups of the upcoming MMA platform in 2024 – the MMA Stromers are to have rear-wheel drive as standard, but will also be offered with a second drive unit at the front as an all-wheel drive option. However, a Mercedes star on the side of the body hints that the eDecoupling unit will be supplied to the Stuttgart-based company. The production start-ups of the first two PPE models Porsche e-Macan (Leipzig) and Audi Q6 e-tron (Ingolstadt) could theoretically also be considered, but the component bears the wrong logo for this.

The new eDecoupling unit is produced at the Magna plant in Lannach, Austria. In future, this will not only be done for premium vehicles: “Our new and innovative modular eDecoupling unit aligns perfectly with OEMs’ in-house manufacturing strategies for electric drive systems,” said Diba Ilunga, President Magna Powertrain. “Due to the compact design of the unit, we’ve successfully minimized added package space and weight in both axial and radial direction, which has helped ensure that it can be scalable for use across electric and hybrid vehicles from B segment up to SUVs and light commercial vehicles.”

0 Comments