MAN has started accepting orders for the eTruck

Both models are based on the same construction kit of the long-distance transport model previously known as the “MAN eTruck”. The differences between the eTGS and eTGX correspond to the familiar diesel models, for example the wider cab of the TGX. In the drive system, however, the modular technology is the same.

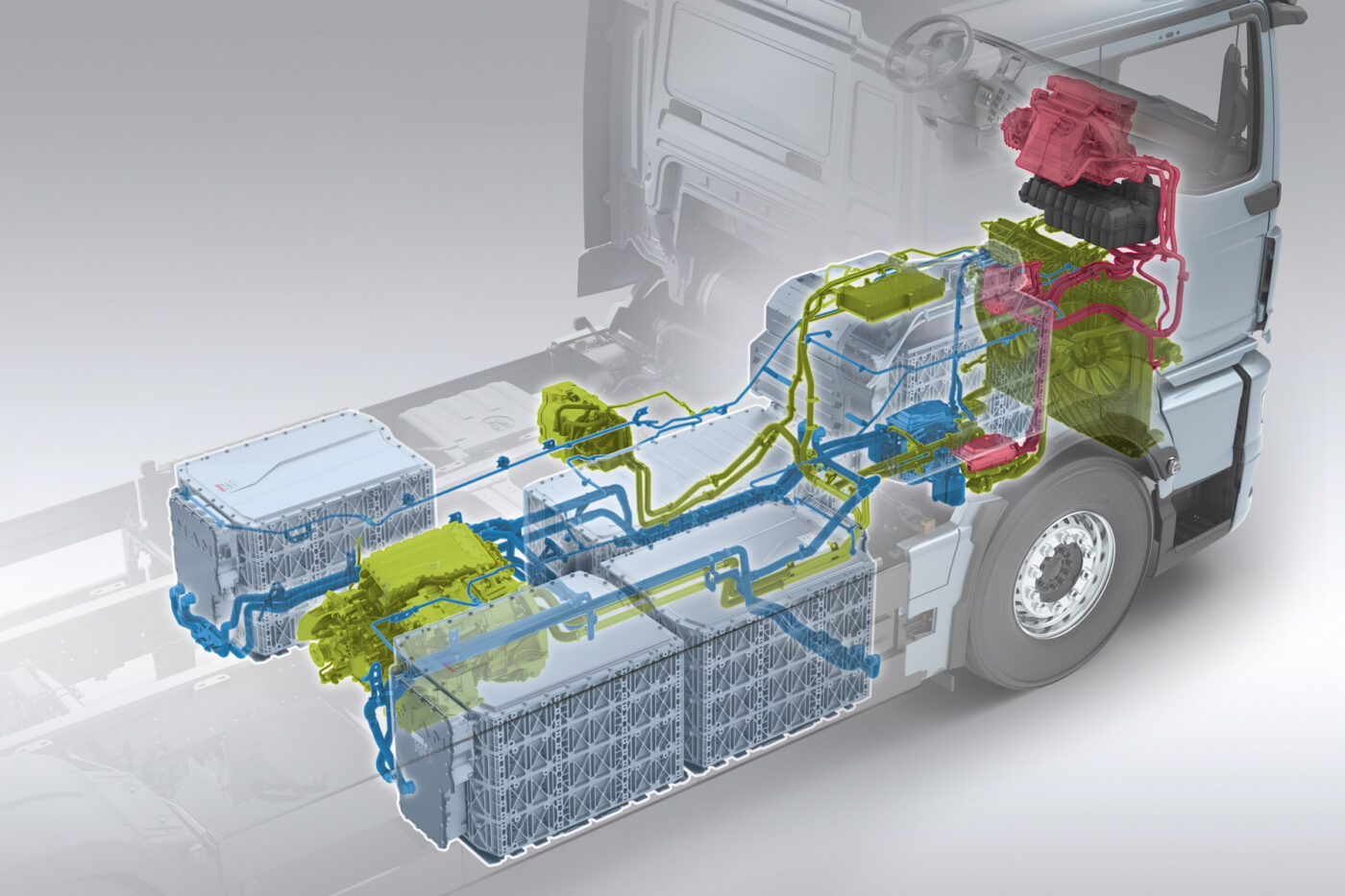

With up to six battery packs, two of which are installed under the cab and up to four more on the side of the vehicle frame, both offer up to 480 kWh of usable battery capacity for daily ranges of up to 800 kilometres. In addition to the CCS standard with up to 375 kW, MAN will offer the even more powerful MCS charging standard for fast intermediate charging during breaks in driving times right from the start of sales, which will initially enable 750 kW, and in a later expansion stage over one megawatt of charging power. With the higher charging power – and thus shorter charging times – daily ranges of up to 1,000 kilometres should also be possible later, according to the manufacturer.

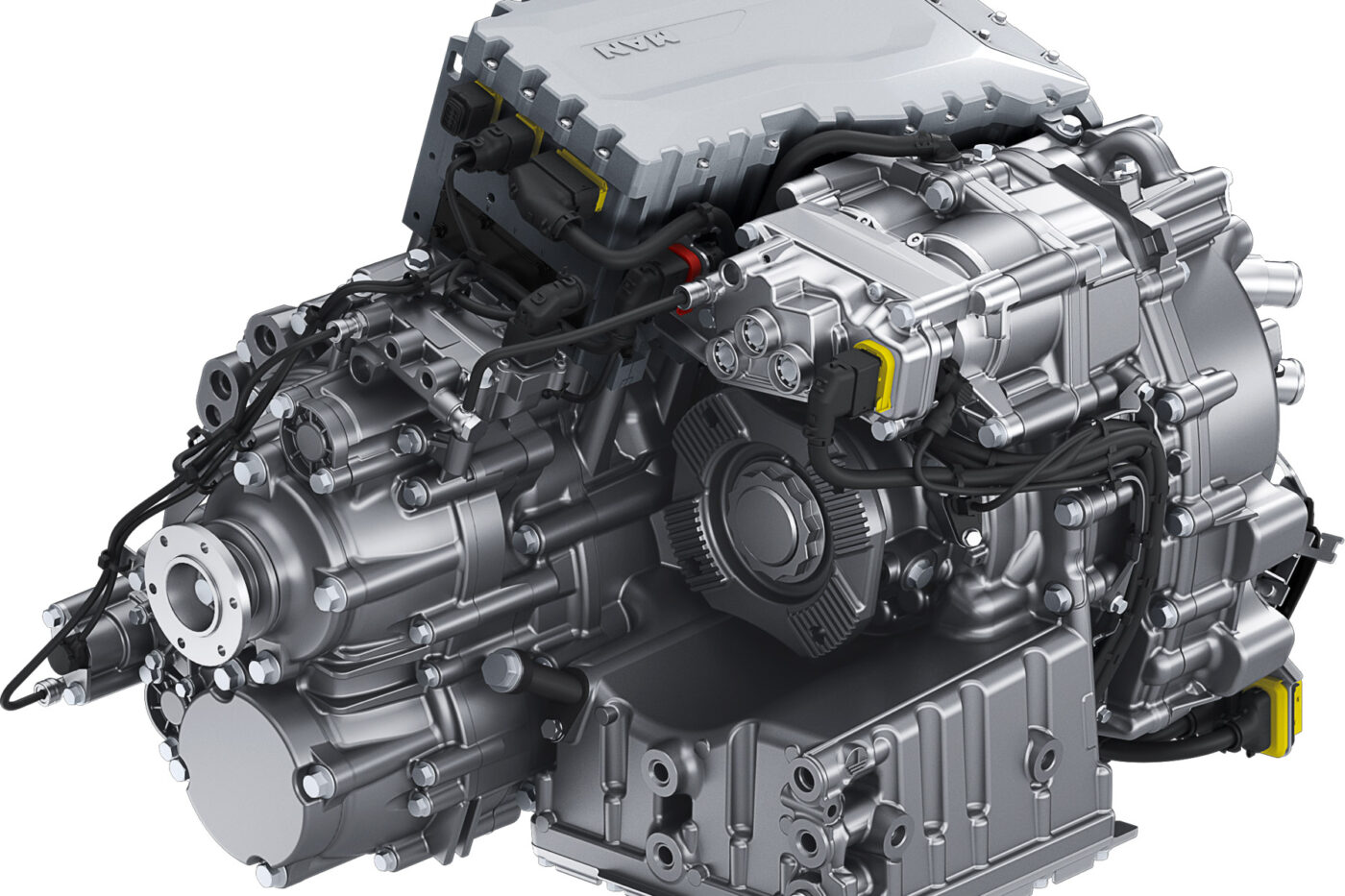

Depending on the application configuration, the electric motor has an output of 254 kW, 330 kW or 400 kW with a corresponding maximum torque of 800, 1,150 or 1,250 Newton metres. The recuperation power during deceleration is said to correspond to the drive power of the respective electric motor. This means that the deceleration is “comparable to that of today’s high-performance diesel engine endurance brakes”.

With the modular battery and body concept, MAN wants to be able to cover the different needs of customers in terms of range, payload and charging time. An MAN eTGS on the road in urban distribution transport usually needs a daily range of around 250 kilometres and is charged overnight in the depot. Here, the MCS option can then be dispensed with and only three instead of six battery packs can be installed – three, four, five or six batteries are possible. According to the press release, the vehicle weight can be reduced by up to 2.4 tonnes – “for more available payload and lower consumption for partial loads or empty runs”.

In order to be able to react to the structural conditions in existing depots, customers have the option of choosing the position of the charging connection. Two CCS connections can be variably combined on the left and right sides behind the front wheel arch or on the right side of the frame at the rear. The MCS connection can also be ordered on the left or right instead of one of the front CCS connections.

According to MAN, the modular battery architecture is intended to make the eTGX and eTGS “particularly body-friendly”. “Free spaces on the left or right of the frame for high-performance pumps, equipment stowage spaces, crane outriggers and similar body components with increased space requirements can be easily realised thanks to the flexible positioning of the batteries,” says the manufacturer. Since not only the batteries but also the drive unit are positioned in a “body-friendly” manner, even very short wheelbases from 3.75 metres become possible, which in turn enables the tractor unit to be combined with all common semi-trailer variants within the permissible overall length specifications. The compact design of the batteries is also the reason why MAN can also offer the new eTruck as a volume variant with a very low frame height for transports with an interior height of three metres – a requirement that is in demand in production logistics, for example.

As with the electric car, heating and cooling the driver’s cab is an important factor in the consumption of the e-truck. To make this as efficient as possible, the vehicle’s overall thermal management system combines the cooling circuits of the cab heating system, drive unit and the temperature management of the high-voltage batteries to efficiently use excess heat generated during operation for the cab heating system and only use additional energy from the batteries for this when necessary. “This guarantees good temperature control even under winter conditions in all cab sizes,” MAN wrote.

“In order to achieve the 1.5-degree target of the Paris climate agreement, we as the commercial vehicle industry must do our part and sustainably reduce CO2 emissions. Electric trucks are the key to achieving this,” says Friedrich Baumann, Executive Board Member for Sales and Customer Solutions at MAN Truck & Bus. “As a commercial vehicle manufacturer, we have repositioned ourselves for this epochal transformation in recent years, making ourselves robust and future-proof to be able to handle the high investments in the new technology. With the sale of our new eTrucks, we are now launching into a new era of climate-neutral transport.”

0 Comments