TU Graz to develop powertrains with AI system

A team from the Institute of Automotive Engineering at Graz University of Technology is combining simulation models of components with evolutionary optimisation algorithms. This AI system automatically optimises the entire drivetrain, from the power electronics to the electric machine to the transmission, in accordance with the technical requirements of the manufacturer. The AI software used for this, OPED (Optimisation of Electric Drives), was developed by TU Graz and is the result of almost ten years of research. According to the university, it is already being used successfully by an Austrian automotive supplier, which is not mentioned by name.

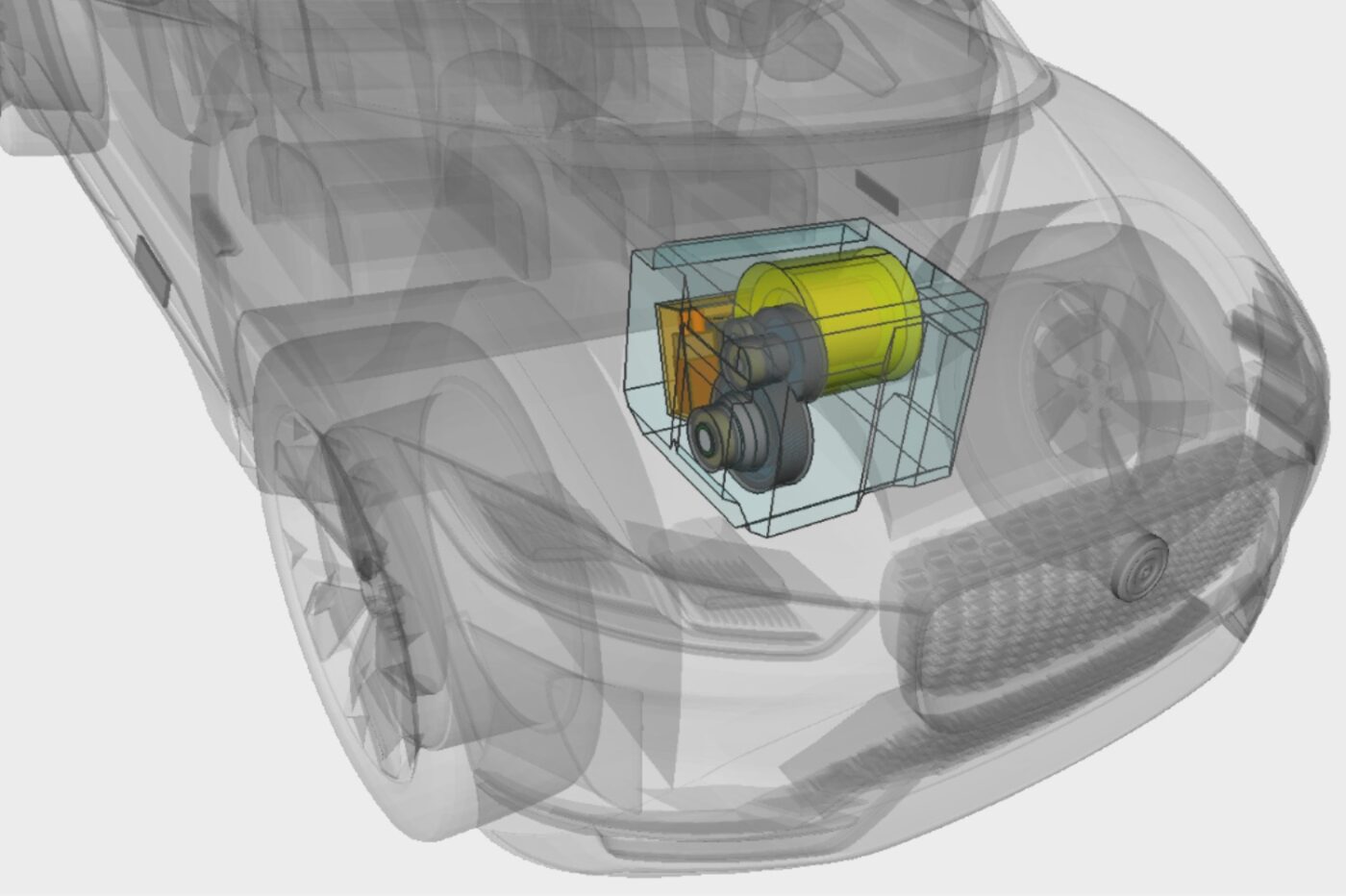

“Electric drives consist of a large number of components that can be designed very differently in order to fulfil the desired requirements,” explains Martin Hofstetter from the Institute of Automotive Engineering at TU Graz. “If I make a small change to the electric machine, it has an effect on the transmission and the power electronics. So it’s extremely complex to make optimal decisions.” An additional difficulty according to Hofstetter is that there is no one perfect solution for a drivetrain, as the manufacturer’s priorities also play a role: These can include production costs, the weight and volume of the drive or energy efficiency.

The starting point for automatic optimisation is the input of the technical requirements that the drivetrain must fulfil: these include the drive power, the minimum service life, the maximum speed to be achieved and the maximum space available in the vehicle. The OPED AI software helps to significantly reduce the complexity of the development process: Based on the technical requirements, the software varies and combines around 50 design parameters simultaneously, comparing the simulated powertrains with the manufacturer’s priorities.

Bad variants are discarded and better ones are further optimised. According to Graz University of Technology, after several hundred thousand calculation and simulation cycles, OPED finds the solutions that come closest to the manufacturers’ priorities. They can then select from a manageable number of variants those that they would like to further develop and implement in detail. “What engineers would need months to do without AI support takes about a day with OPED,” says Martin Hofstetter. “This allows the development teams to focus on top-level decisions instead of investing their limited time in manual calculation and simulation work.”

The OPED system can also be flexibly expanded and can now also take into account CO2 emissions across the entire supply chain, for example. As a recent innovation, Dominik Lechleitner has succeeded in extending OPED for the optimisation of electric drives of an entire vehicle platform as part of his dissertation: the method helps to find optimal components that can be used as identical parts in the drivetrains of different models of a platform in order to save development and production costs.

“The OPED approach can be used for a wide variety of product developments,” explains Martin Hofstetter, “and we are happy to work with new industrial partners to adapt it to their challenges and goals.”

0 Comments