Continental presents temperature sensor for electric motor rotors

According to the automotive supplier, the electric motor rotor temperature sensor (eRTS) delivers significantly more precise measurement results than the current software-based temperature simulation, with a tolerance range reduced from 15 to just three degrees Celsius, as Continental reports.

However, the possibilities that this opens up for the development of new electric motors are greater than a smaller tolerance range of a few degrees would lead the layman to expect. This is because the eRTS and the data obtained from it can help vehicle manufacturers reduce the amount of rare earths used. These are used, for example, to make the magnets inside the PSM rotors more heat-resistant. With precisely measured rather than calculated temperatures, not only can the rare earths be dosed more accurately during development, but the cooling system can also be controlled more precisely and purposefully during operation. If the limits of the previously generous tolerance range are utilised, performance can also be increased.

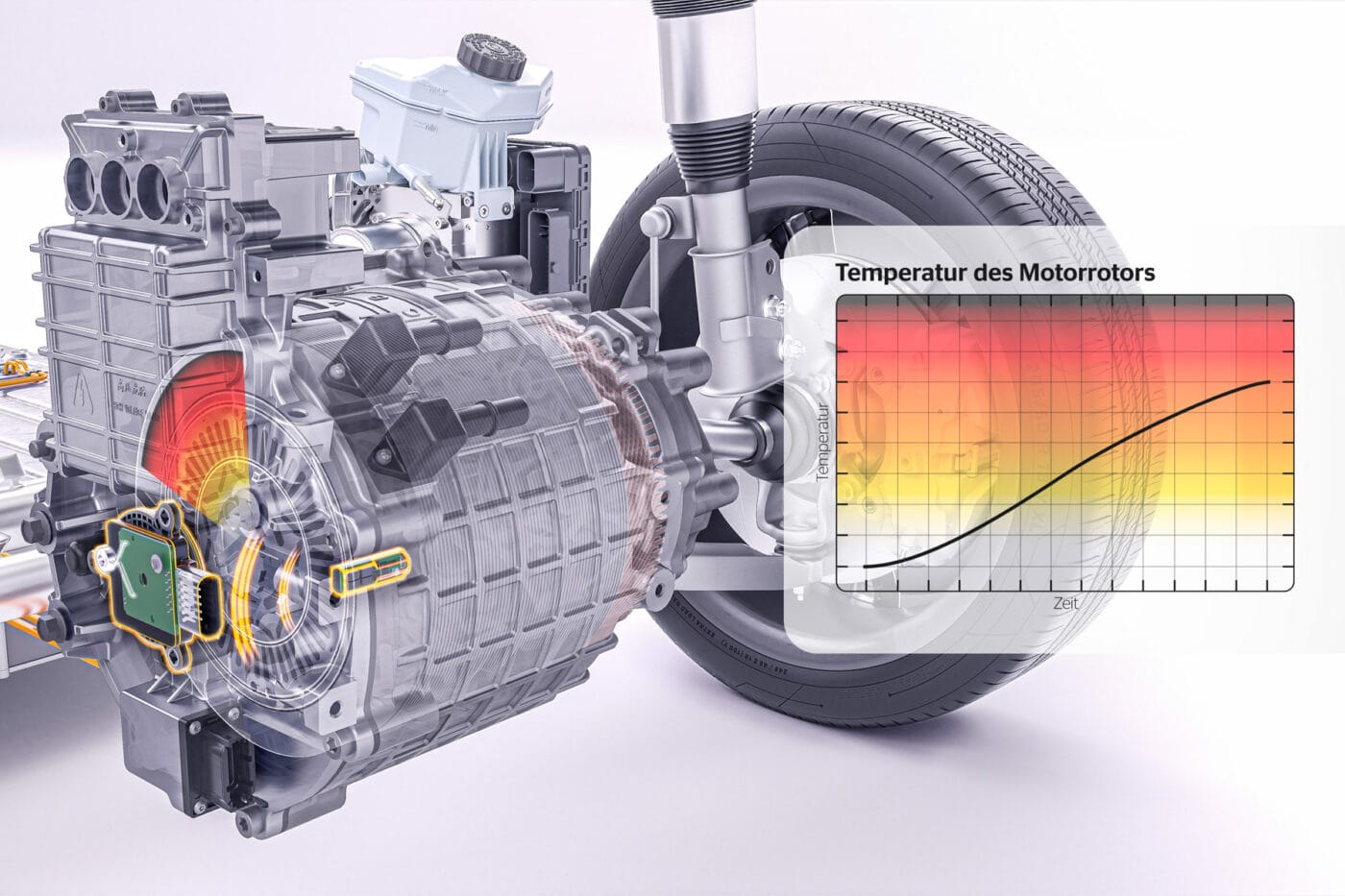

The rotors can reach temperatures of up to 150 degrees Celsius under full load and must therefore be cooled – if the permanent magnets become too hot, they can demagnetise and thus lose their most important property. The solutions currently in use do not measure them directly, but calculate them based on information from the stator temperature sensor, phase current measurements and environmental variables, as Continental explains – but the simulation has a tolerance range of up to 15 degrees. The two-part eRTS – a small sensor called ‘Mote’ is located near the magnets in the rotor, a receiver unit called ‘Transducer’ outside the motor – is intended to provide a significantly more precise temperature value. The transducer is connected to the inverter controller and transmits the temperature measurement data to it via a communication interface.

“With less resource consumption and lower costs, eRTS sensor technology is advantageous to current solutions,” says Bin Huo, Head of the Passive Safety and Sensorics (PSS) segment in Continental’s Automotive division. “This innovation shows that investing resources and focusing expertise in our product center were the right decision. We will continue to successively expand our EV sensor portfolio.”

“Our E-Mobility Sensors product center aims to increase efficiency and sustainability in electric vehicles,” added Christoph Busch, Head of the E-Mobility Sensors Product Centre. “The eRTS technology is a good example of this: reducing the use of rare earths contributes to a more sustainable supply chain, especially given that the number of EVs is expected to greatly increase in the coming years and decades. In combination with other sensor technologies, such as the e-Motor Rotor Position Sensor, it can even act as a system solution to create synergies that can save car manufacturers money and effort.”

0 Comments