New high-voltage battery sensor from LEM aims to reduce costs

LEM (short for Life Energy Motion) specialises in electrical measurement solutions for energy and mobility applications. The company’s products are also used in electric vehicles and related components.

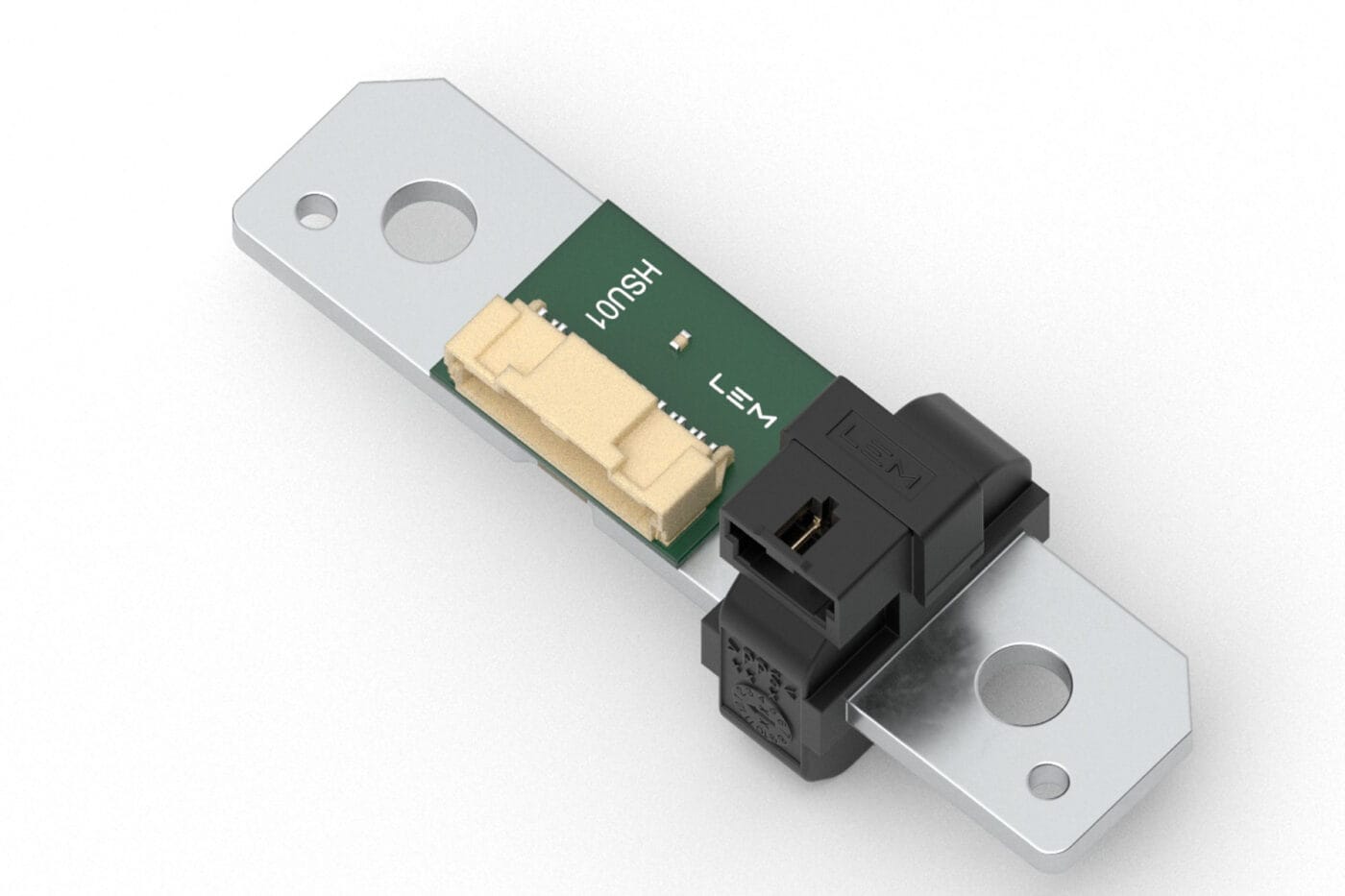

The newly introduced high-voltage battery sensor is designed to expand LEM’s offering in this segment. The component integrates shunt and open-loop Hall effect technologies into what LEM calls a ‘Hybrid Supervising Unit’ (HSU). These technologies are typically housed in separate components, but the HSU is intended to meet the requirements for reduced space, lower costs, and high safety in EV battery management systems, according to the company.

Shunt technology enables current measurement, while the Hall effect is used for precise magnetic field detection. For safety reasons, battery management systems (BMS) in electric vehicles currently use both a shunt for current measurement up to 2,000 A and a fully galvanically isolated current sensor—until now, as two separate parts. LEM’s new development is designed to combine the function and performance of both technologies into a single unit.

Within the battery pack, the HSU is integrated into the Battery Disconnect Unit (BDU). Although it is a single component, the BMS can independently read both signals—shunt and current sensor.

According to LEM, the HSU is “the only component on the market to combine both technologies in a standard shunt footprint.” Initially, two variants are available—HSU00 and HSU01—both designed for compatibility with the most common BDU busbars. The HSU00 measures 84 mm × 36 mm × 3 mm, while the HSU01 (shown above) measures 84 mm × 20 mm × 3 mm. Sample units of both models are available immediately, LEM reports.

The company also plans to expand the range using new technologies, “for example by combining a shunt with a coreless Hall-effect component.” The goal is to further reduce component size and cost while improving performance.

“The HSU represents a significant innovation in sensor technology, being the first to combine shunt and Hall effect sensing into a single component. This integration simplifies system architecture, enhances safety, and allows for seamless upgrades without altering the mechanical layout,” said Jérémie Piro, Product Manager Battery Management Systems and Battery Storage at LEM. “Additionally, it reduces the total bill of materials (BOM) and minimizes cycle time at the customer’s end.”

Source: Information per e-mail (in German)

0 Comments