Milence is one step closer to completing Europe’s first MCS corridor

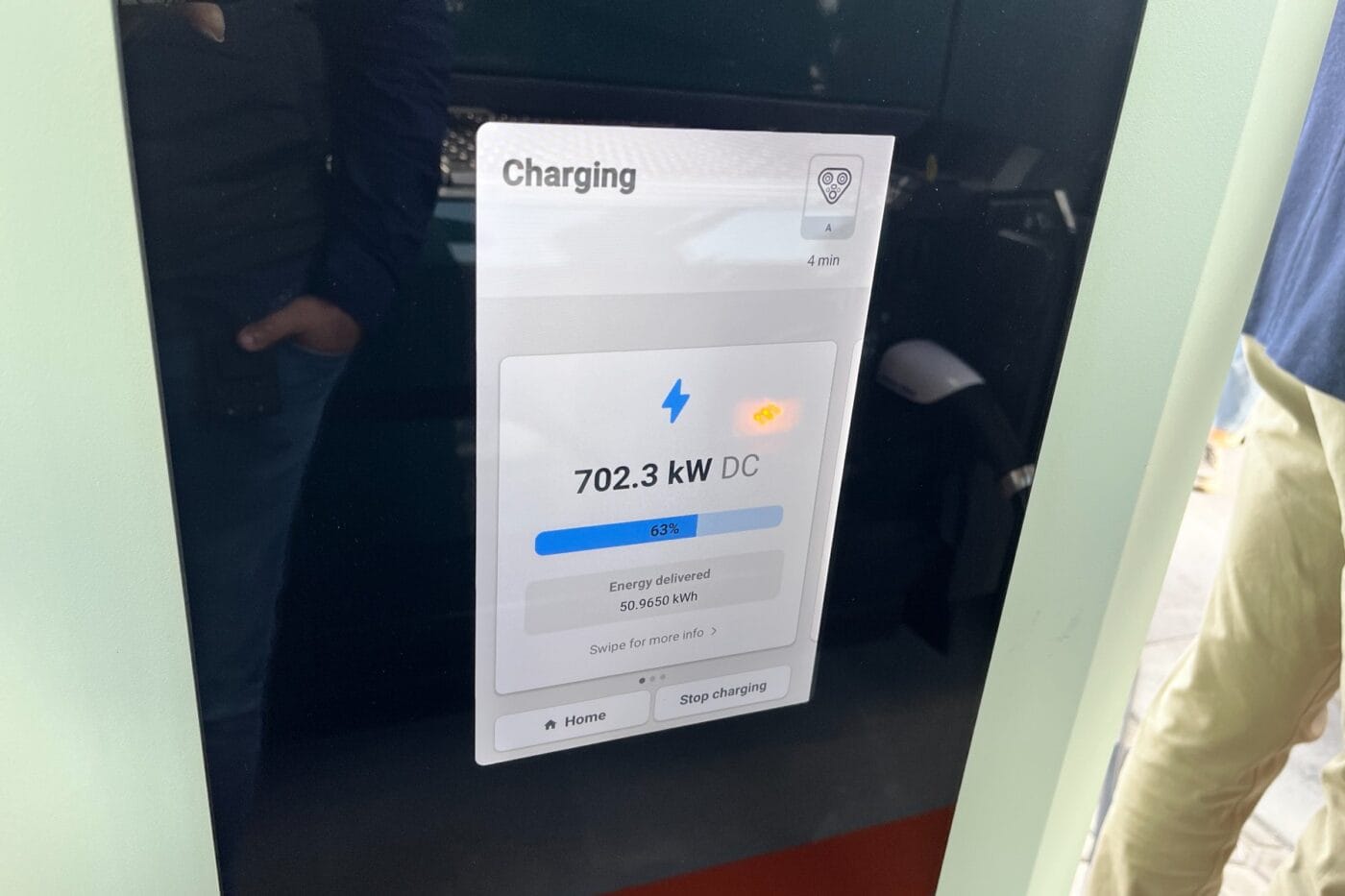

Milence has officially unveiled the first public MCS chargers for electric heavy-duty vehicles in Sweden. The new charging station from Power Electronics is located at its charging hub in Landvetter, near the Gothenburg Airport. The new charger delivers up to 1,440 kW (1,500 A at 1,000 V), enabling charge times of 30 to 45 minutes.

The Landvetter site first came online in December 2024. It has now been upgraded to offer the Megawatt Charging Standard, and thus now includes eight CCS bays and one MCS bay. The site’s CCS capacity has also been doubled, reinforcing Milence’s strategy of building a high-power corridor for electric trucks across the continent.

“This is an important milestone for the entire sector as we’re demonstrating that electric, sustainable road transport is no longer a future ambition, but a reality,” said Anja van Niersen, CEO of Milence. “The expansion of our Landvetter hub with Megawatt Charging brings us one step closer to establishing Europe’s first MCS-enabled corridor.”

Milence was founded as a joint venture in 2022 by Daimler Truck, Traton and the Volvo Group, and aims to have up to at least 1,700 high-performance charging points across Europe by 2027. Following MCS installations in Antwerp and Zwolle, the Landvetter site is now Milence’s third hub to feature MCS chargers. The above-mentioned MCS corridor will connect Antwerp and Stockholm along two major TEN-T routes, spanning over 1,500 km. Milence plans to install 284 MCS points across 71 sites in ten EU member states.

Transformation could happen overnight, but challenges remain

“With three sites up and running, we know by now what works,” said van Niersen. “It’s not that different anymore, but it’s always in the testing – the communication between truck and charger – where there is some fine-tuning. Interoperability remains a key challenge because there are still very few trucks out there that can use MCS. We’re working with all OEMs to change that.”

Despite limited real-world usage today, MCS-enabled trucks are expected to begin entering series production from 2026. “We expect as of the first, second quarter of 2026 that we see the first one really coming to the market,” van Niersen told electrive.

While grid constraints pose a major hurdle across Europe, Milence is developing solutions that adapt to local limitations. “We prioritise sites with minimal grid challenges,” van Niersen explained. “Some locations start at lower power and ramp up as capacity becomes available.” Milence also tries to co-locate with renewable energy producers where possible and share grid access, which as van Niersen explains, helps both the grid and the CPO. Asked about the cost of grid connections, van Niersen highlighted the variability: “It can be €30,000 per megawatt or €3 million, even within the same country. It depends on the Distribution Network Operator (DNO), the distance to the substation, and the need for reinforcement. You can’t generalise it as a percentage of project costs.”

As for 2030, she foresees a rapid acceleration: “This transformation won’t be linear. It may flip overnight. Some fleets are already phasing out diesel. The question is: can infrastructure scale fast enough? Financing is now the biggest hurdle. Once that’s solved, I see no reason why 50% of new trucks by 2030 couldn’t be electric.”

Volvo Trucks upcoming FH Aero Electric plugs in

According to Milence, Sweden is a leader in truck electrification and has over 1,000 electric long-haul trucks on the road and more than 150 public charging stations – Europe’s highest density. The public demonstration of the first charging session of a Volvo Trucks FH Aero Electric took place during EVS38. The electric truck supports up to eight battery packs with a total capacity of 780 kWh. With an estimated range of up to 600 kilometres, it is designed to to electrify long-haul freight operations. Using MCS, charging from 20% to 80% takes roughly 40 minutes, which aligns with EU-mandated driver rest times.

As at its other sites, Milence offers flexible payment options, including support for multiple e-Mobility Service Providers, direct on-site payments, and the Milence Charge Card. Charging is priced at €0.399 per kWh (excl. VAT) for both CCS and MCS. Looking ahead, Milence is preparing for dynamic pricing models but will roll them out gradually. “We need to give confidence to the market first. Over time, we’ll see pricing mechanisms based on time of day, energy source, or usage volume,” said van Niersen.

Nevertheless, regarding pricing and total cost of ownership (TCO), van Niersen emphasised that charging costs are already competitive in some regions: “Driving an electric truck is already a very good idea in places like Germany or the Netherlands with tax incentives. It’s more the vehicle purchase cost – which is still 2.5 times higher than diesel – that’s the issue.”

The electric truck CPO first tested megawatt charging in July 2024, also using hardware from Power Electronics. It is that very same hardware that has been installed at the site in Sweden, as well as in Belgium and the Netherlands.

The Megawatt Charging System (MCS) will be the standard for high-performance charging, tailored to the requirements of the growing market for electric trucks. It is designed for a charging voltage of up to 1,250 volts and a current of 3,000 amps, which theoretically corresponds to a charging capacity of up to 3.75 megawatts. By comparison, today’s charging stations with the CCS standard (Combined Charging System) can be used by cars and commercial vehicles and offer a maximum charging capacity of 400 kW at 500 amps. Unlike with electric cars, the position of the charging port on the vehicles is standardised for the MCS.

The charging port will be on the left-hand side of the vehicle, in an area between two and 4.80 metres behind the bumper. It should be located there at approximately hip height. This standardised position is intended to simplify the installation of the charging parks. CharIN has already shown the first charging system layouts.

0 Comments