Schaeffler introduces electric axle drive repair tool

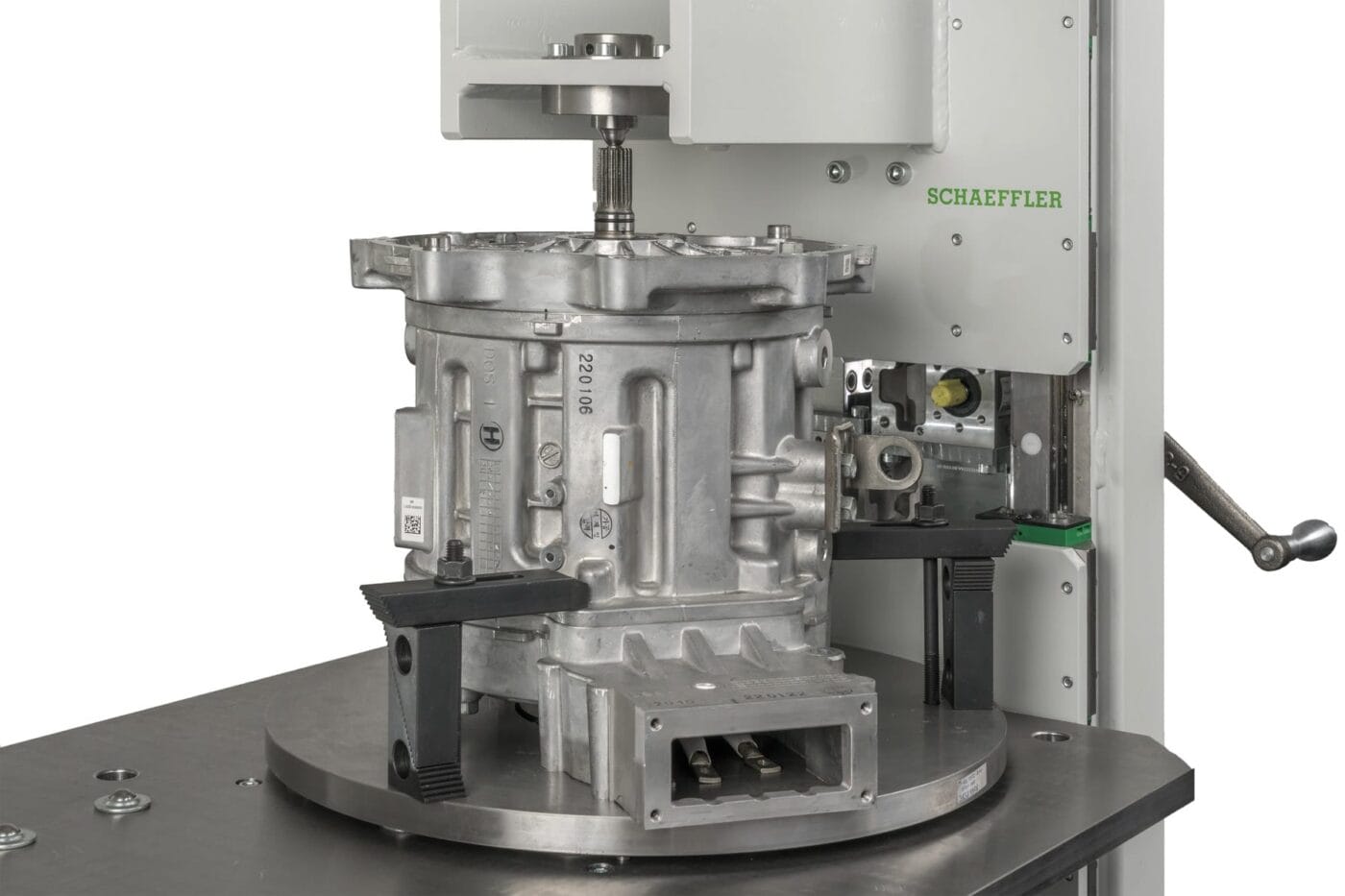

According to Schaeffler Vehicle Lifetime Solutions, the new tool enables “precise, non-contact disassembly and reassembly of rotors and stators.” This step is necessary in order to access the interior of an electric motor and reassemble the motor later on. However, due to the materials used, separating the rotor and stator is not as easy as it sounds.

Permanently excited synchronous motors have strong permanent magnets built into the rotor. The magnetic forces that occur there make it difficult to pull the rotor out of the stator and the metal housing. The construction of the E-Axle Repair Tool is designed to ensure that the radial distance is reliably maintained despite the strong magnetic forces, both when dismantling the motor and when reassembling it after repair. Pressing forces of up to 10,000 newtons enable even strongly adhering seals to be loosened without any problems and new bearings to be pressed in, without causing any damage to the components.

“Precise guidance during rotor removal is essential to prevent contact between components. Any abrasion left inside the motor could lead to damage,” explained Stephan Niese, Director Global Product Management ePowertrain Schaeffler Vehicle Lifetime Solutions. In addition, the E-Axle Repair Tool is designed to enable users to work easily and ergonomically, thanks to unrestricted access via three open working sides.

As the tool is universally designed, it is not only suitable for individual motor models, but can also be used for a wide range of different drive units. The E-Axle Repair Tool, which is available now, is “suitable for all garages focusing on electric motor repair and looking to tap into new business opportunities,” according to Schaeffler.

The idea behind it is clear: repairing rather than replacing an engine is not only cheaper for the end customer but also more sustainable. “Repair instead of replace: that requires the right specialized tools. As a technology pioneer, we are setting the standards,” said Niese. “This new tool opens the door to the world of electric motor repair – and to the future of the e-powertrain. We’re making e-mobility more sustainable, economical, and repairable.”

This article was first published by Sebastian Schaal for electrive’s German edition.

0 Comments