European project Stellar develops anode production for lithium metal batteries

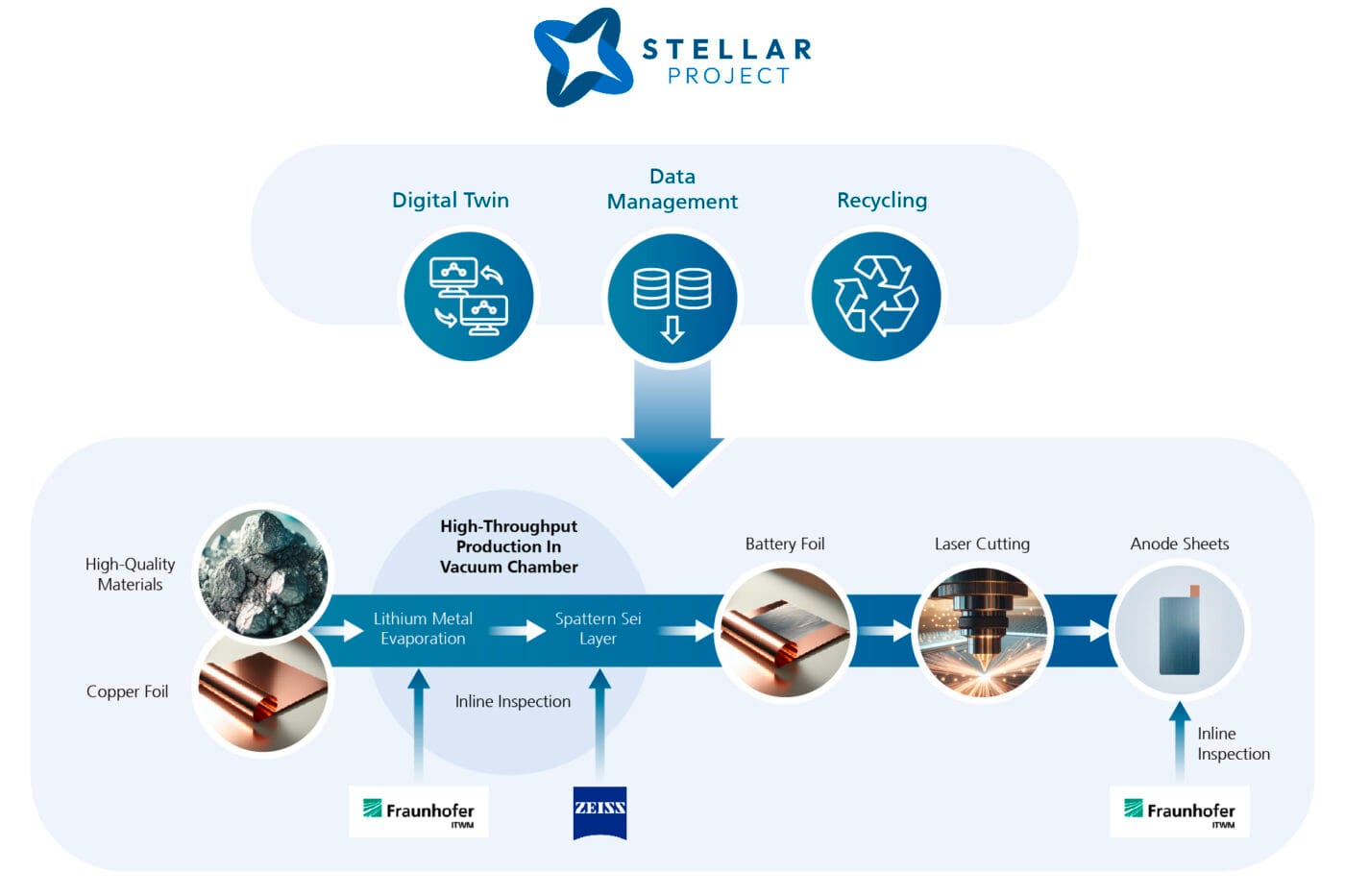

Lithium metal batteries (LiM) have a higher energy density than lithium-ion batteries, but still face challenges before becoming commercially viable. The EU project, Stellar, which carries the full title of ‘Safe, Sustainable, and High-throughput Production of Reliable Lithium Metal Anodes for Gen 4b/4c/5 Batteries,’ aims to enable the manufacture of highly reactive lithium metal anodes in a safe and reproducible way.

Project funding from the European Commission amounts to 7.9 million euros over a four-year period, which began in June 2025 and will run till 31 May 2029. The project will be carried out at a pilot plant at Belgian company Avesta Holding, a developer and manufacturer of lithium batteries, which is coordinating the project. This will be a new roll-to-roll test facility for efficient next-generation lithium metal anodes.

In a vacuum chamber, the thin lithium layer is applied to wafer-thin copper foils. This manufacturing process for lithium metal battery anodes involves a roll-to-roll production plant facility that continuously unwinds the foils from one roll, processes them, and then rewinds them onto another roll. The research will monitor film properties during this process under complex vacuum conditions, with key parameters such as layer thickness, surface texture, electrical conductivity and the quality of cutting and edges.

Fraunhofer ITWM is funded to develop optical measurement technology for the anode rolls. Dr Stefan Duran, project manager at Fraunhofer ITWM explains, “With our broad portfolio of measurement technology, we can individually adapt the most suitable methods to the very specific requirements.”

According to Fraunhofer ITWM, the production technology being developed with the Stellar project is particularly efficient for manufacturing large-area, flexible products. The new plant is expected to achieve an industrial production capacity of around 60 kilometres of anode foil per year, whereby the project partners hope to ensure a precise lithium layer thickness within the range of 5 to 15 micrometres.

According to the European Commission funding website, the Stellar project additionally aims “to ensure future seamless integration in the European market, a data-driven DT with quick response times for integral process optimisation will be developed, as well as the design at module/pack level of the LiM-based batteries.”

0 Comments