Nissan begins series production of the new Leaf

With the third generation of its electric pioneer, Nissan has undergone a conceptual transformation—shifting from a compact car oddity to an electric crossover built on mass-production technology, in this case based on the group’s CMF-EV platform. A first test drive around Copenhagen demonstrated how the new Leaf performs, as detailed in our impressions. The battery now offers up to 75 kWh of capacity, and the Leaf supports charging at up to 150 kW. The base version is expected to be priced under €37,000, while the larger-battery variant will cost under €42,000.

Production of the Leaf for Europe—just as with the two previous generations—takes place at Nissan’s plant in Sunderland, UK. For the third generation, the Japanese manufacturer has once again made significant investments in the site, totalling £450 million (currently equivalent to just over €510 million). Until now, the Leaf was produced alongside the internal combustion SUV Qashqai on the same line. For the third generation, Nissan states that it has ‘redesigned the Sunderland plant and now enables the production of electric vehicles on production line 2 for the first time.’

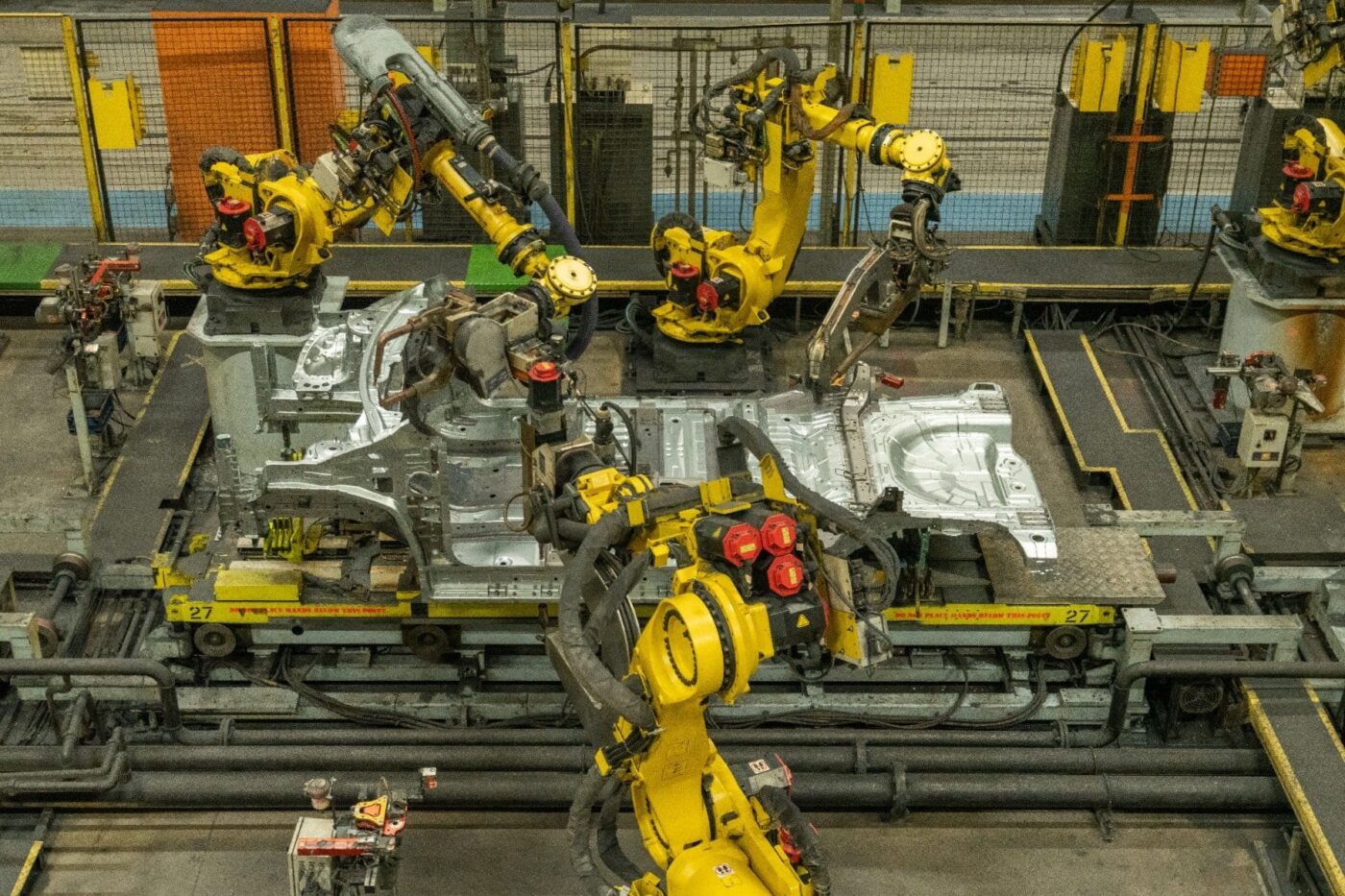

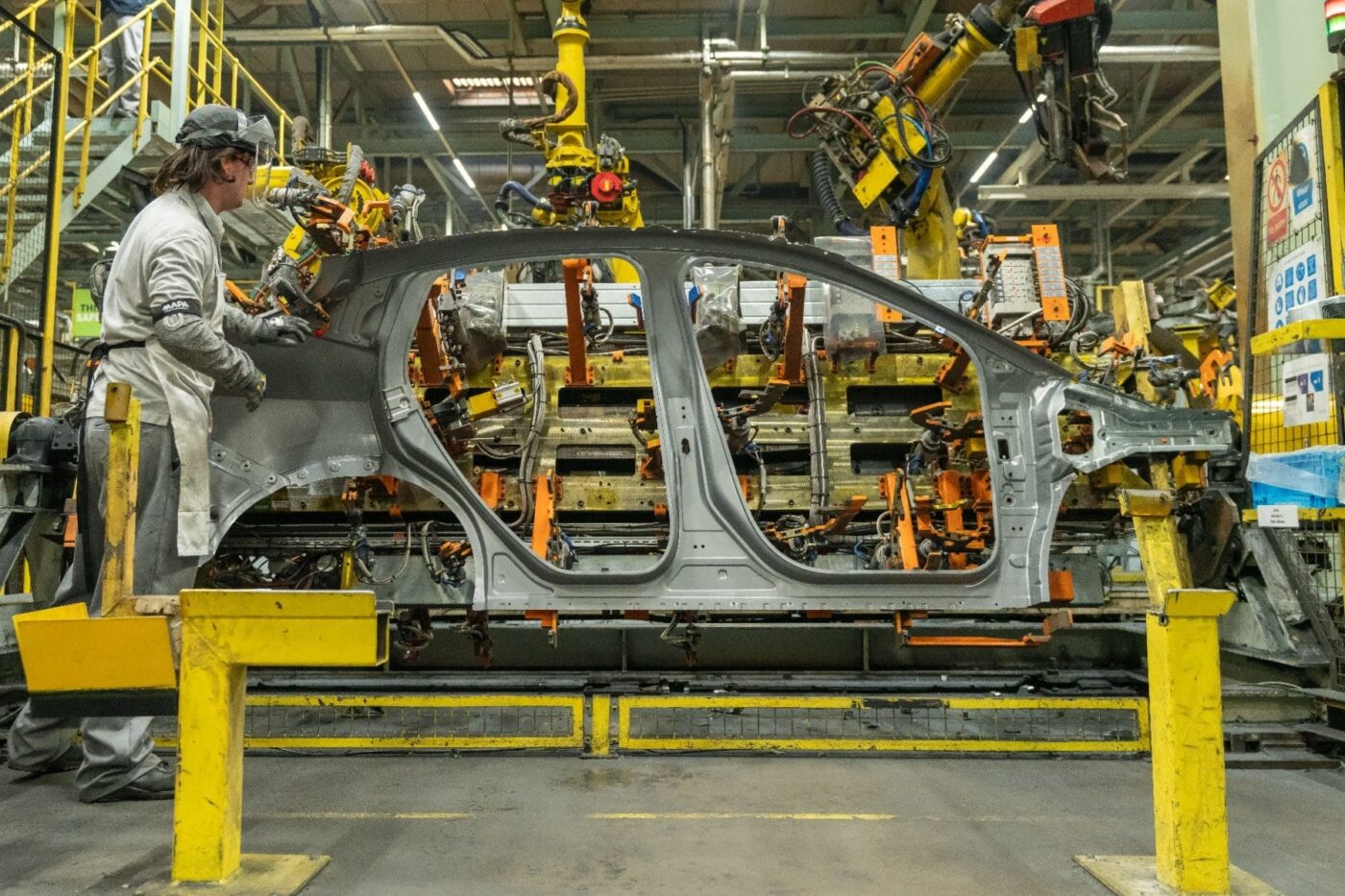

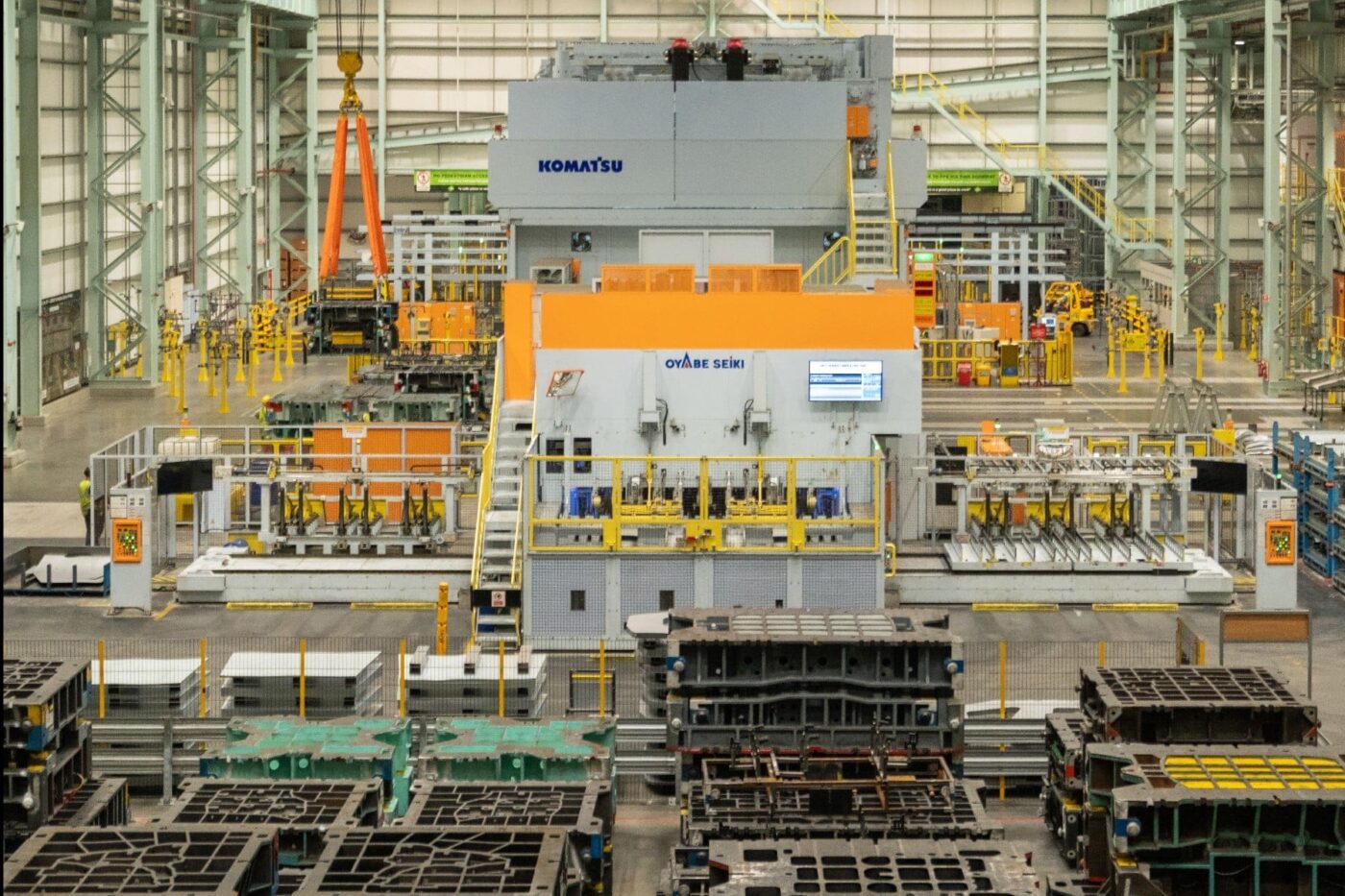

To build the new model in Sunderland, Nissan has procured 137 new pressing tools, which are used to manufacture a total of 42 different body parts for the Leaf. The existing production robots have been supplemented with 78 new high-tech robots in body construction, ‘including a fully automatic laser welding system that ensures precision of 0.3 mm.’ The paint shop has also been upgraded to expand the colour palette with the ‘vibrant new colours Sukumo Blue and Luminous Teal’—Luminous Teal being the turquoise shade seen in most press images. Additionally, 475 new driverless transport systems deliver parts directly to the production line.

The plant has also been expanded to include a new battery assembly line. “This fully automated technology installs the battery into the vehicle and secures it with 26 bolts in 56 seconds,” according to Nissan. A significant portion of the battery’s value chain is now local, though the supply chain also reflects the eventful history of the previous Leaf generations; Nissan initially established its own cell production facility adjacent to the vehicle plant, producing cells in Sunderland for the Leaf manufactured there and the e-NV200 electric van in Barcelona. Later, the Japanese company sold its battery division under the name “Automotive Energy Supply Company” (AESC). That same company, now under new ownership as AESC UK Battery Manufacturing, has since built a new gigafactory in Sunderland to produce battery cells for the new Leaf, among other models.

“Today is a memorable day, as we begin production of the third generation of the Nissan Leaf in the UK—the electric vehicle that started it all,” said Massimiliano Messina, Chairman of Nissan Africa, Middle East, India, Europe, and Oceania (AMIEO). “The Leaf brings our world-first EV36Zero vision to life, uniting electric vehicle manufacturing, battery production, and renewable energy.”

Adam Pennick, Vice President of Manufacturing at Nissan’s Sunderland plant, added: “Nissan has invested in our state-of-the-art plant to build the electric vehicles of the future, and our team is incredibly proud and excited to be manufacturing this fantastic car in Sunderland.”

0 Comments