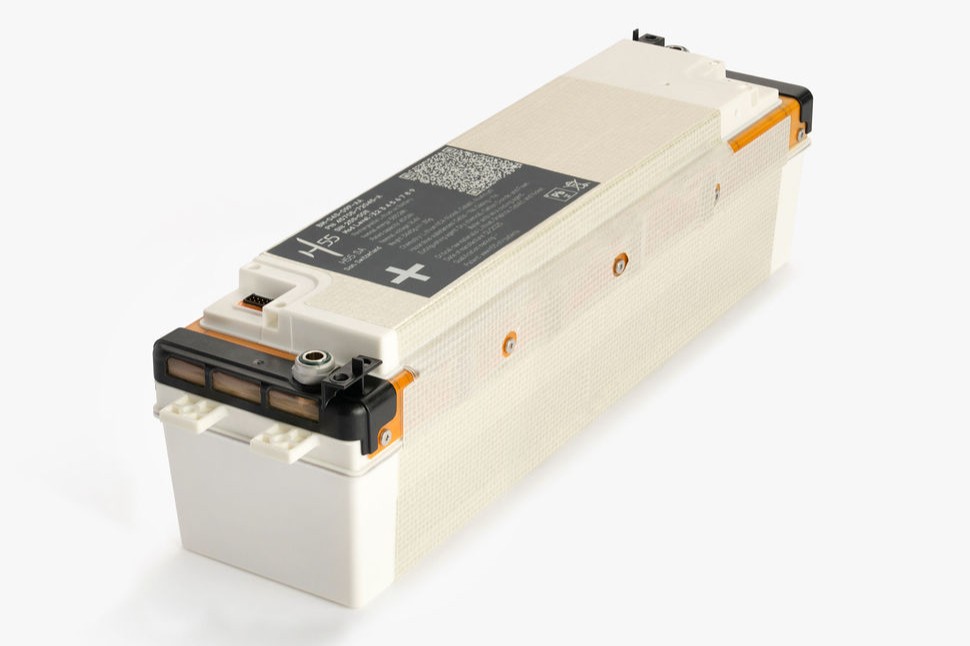

H55 completes certification tests for propulsion battery modules for electric aircraft

Under the oversight of the European Union Aviation Safety Agency (EASA), H55 has provided certification-relevant evidence demonstrating that commercial lithium battery cells can be safely integrated into propulsion battery systems for aviation. These systems operate reliably even in worst-case scenarios, particularly in the event of fire propagation. However, certification is not yet complete: the results are currently being documented in final test reports, which H55 intends to submit to EASA for formal approval in the first quarter of 2026.

“By providing monitoring, active and passive protections of every individual cell, H55 transforms the propulsion battery from a ‘black box’ of latent risk into an actuarially transparent asset, establishing cell-level monitoring as the non-negotiable threshold for both regulatory type certification and fleet insurability. What’s most exciting, is the engine-like business model this enables for H55,” says CEO Rob Solomon.

Damage mitigation at cell level

“By designing protection, monitoring, and mitigation directly at cell level, rather than relying on pack-level assumptions, we have built a fundamentally different Energy Storage System. This cell-level architecture not only enables effective protection at the point of origin, but also allows us to optimise battery efficiency, performance, and long-term reliability — all of which are essential for certifiable electric aviation,” added CTO Sébastien Aymon-Demont.

H55 originated as a technological legacy of André Borschberg and Bertrand Piccard’s Solar Impulse project. The company has accumulated over 2,000 accident-free flight hours with electric systems, for example, with the Bristell Energic, tested from 2019, a two-seater. However, H55 does not aim to manufacture its own electric aircraft but positions itself as a technology supplier, specialising in electric propulsion systems.

The propulsion battery system test campaign was recently conducted in a certified production facility using series-conform hardware (not prototypes), manufactured through validated processes. It confirms H55’s ability to develop and produce propulsion battery systems built to certification standards on regulatory-approved production lines and supply chains.

Repeatable certification pathway

According to the Swiss company, this approach creates a repeatable certification pathway for H55’s battery technology, rather than advancing a single aircraft programme. The certification evidence can be applied to a variety of aircraft platforms. The system foundations established by H55’s propulsion battery system are now set to accelerate the development and regulatory progress for both fully electric and hybrid-electric aircraft, such as the BRM B23 Energic, CAE’s transition to fully electric pilot training platforms, and the Dash 8 hybrid-electric demonstration programme with Pratt & Whitney Canada.

Source: via email, h55.ch

0 Comments