Freudenberg: Heat shields improve battery safety

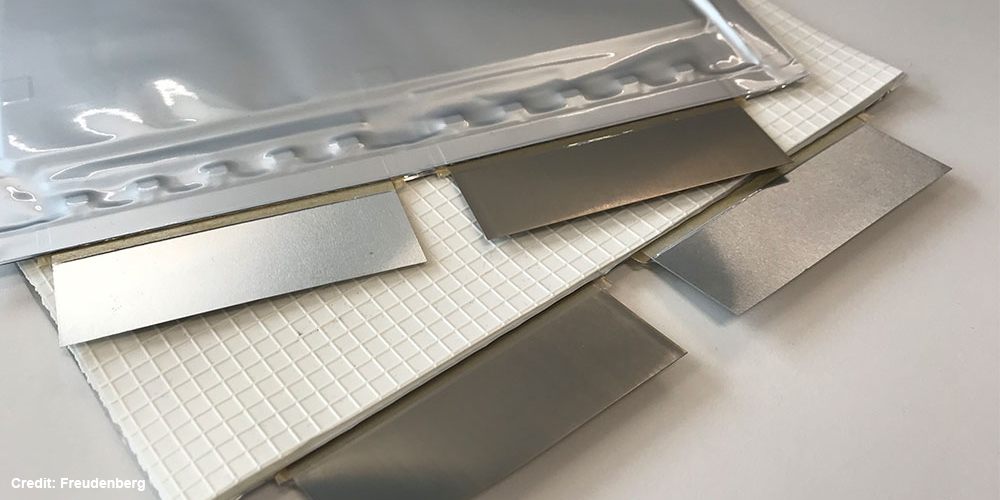

To prevent that a single, damaged battery cell overheating the entire battery module, Freudenberg Sealing Technologies has developed a heat shield that can be used in prismatic and pouch cells with almost no space impact.

It combines the high heat resistance of a silicone-based elastomer with the temperature isolation from the surrounding air. In future, heat shields in individual cells will ensure that the excess heat from a damaged cell can be isolated long enough until it has dissipated.

The heat shield fulfills three basic aspects: first it is constructed of a heat resistant material; a silicone based elastomer. Secondly, it delays the heat transfer between cells through a waffle structure – tiny air bubbles further isolate heat. Finally, the heat shield is very thin, with a maximum width of 1 millimeter. The energy density lost to the installation of the shield is barely notable.

The development of the heat shield required Freudenberg Sealing Technologies to establish a new testing method. It works by placing the heat shields on a 600 degree Celsius surface, and then testing the temperatures on the back side of the shield. Tests showed that even after 30 seconds on the heating surface, temperatures on the back of the heat shield were under 200 degrees. “This will adequately protect a neighboring cell against the destruction of cathode material or the separator,” said Freudenberg expert Peter Kritzer. “The exact boundary values admittedly depend on a multitude of specific parameters such as the chemistry and geometry of the battery cells.”

Testing on battery modules and systems can now begin. There is also some thought as to how the shields could be ideally mounted. At the same time, development teams are also looking at further developing the heat shields capacity.

0 Comments