Rethmann subsidiaries launch battery recycling company

Rhenus Automotive and TSR Automotive – both subsidiary companies of the Rethmann Group – have founded the joint company The Battery Lifecycle Company GmbH (BLC). The declared aim is the reuse and recycling of lithium-ion batteries from the mobility sector.

With the plan to offer holistic battery recycling along the entire value chain, BLC wants to “handle all the processing stages, ranging from the initial inspection to deep discharging and even repairing and dismantling the lithium-ion batteries, most of which will come from the automobile industry”, according to the announcements by Rhenus Automotive and TSR.

The operational management of BLC will lie with TSR Automotive, as the subsidiary of TSR Recycling also holds 65 per cent of the new GmbH. The remaining 35 per cent will be held by Rhenus Automotive.

Initially, BLC will operate from the TSR site in Rheda-Wiedenbrück. Battery packs have already been dismantled here since 2021 and examined for their suitability for reuse. In other words, functional batteries whose performance is no longer sufficient for automotive use will be prepared for second-life use, for example in stationary storage systems. Damaged or defective modules are deep-discharged and disassembled.

Europe’s first fully automated discharging and dismantling facility

In future, the joint venture will also use high-performance components as replacement modules for repairs and in the reconditioning of battery packs. For this purpose, the joint venture is already planning another dismantling line at the TSR site in Magdeburg, which is to go into operation at the end of 2023. This will be the first fully automated facility for discharging and dismantling battery modules in Europe.

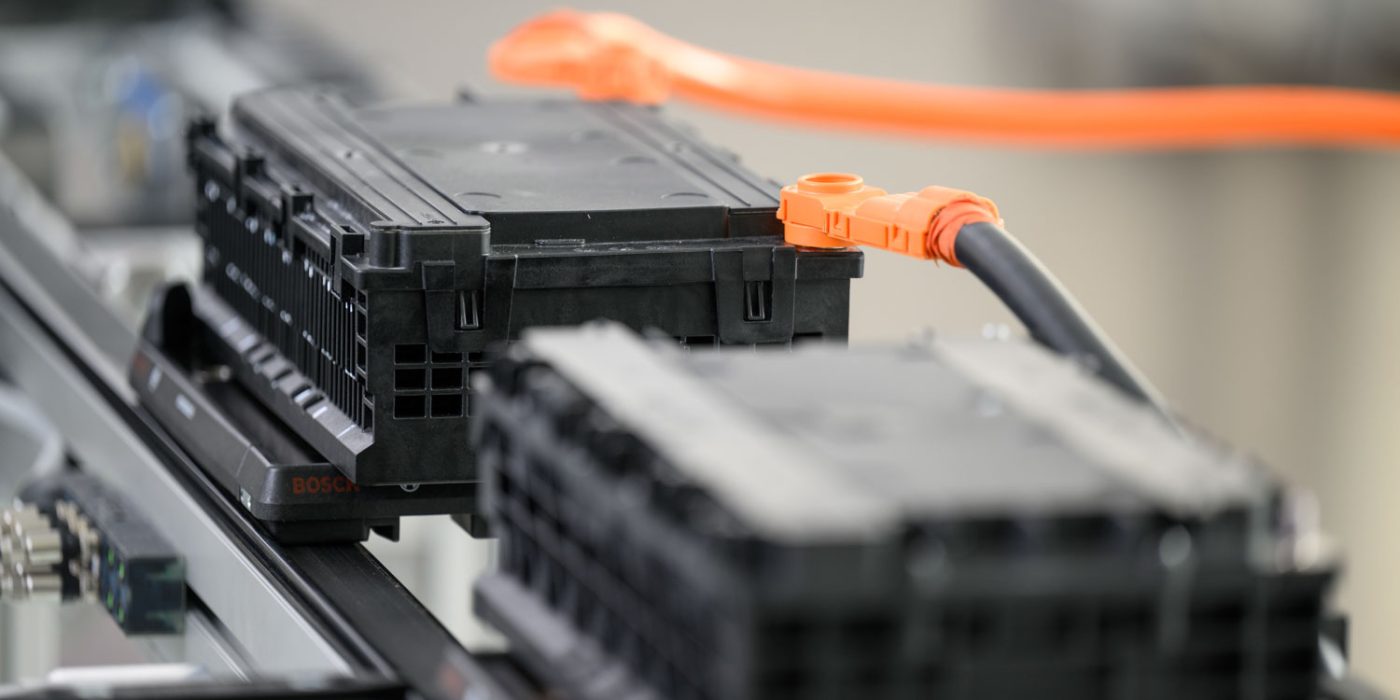

Bosch Rexroth will supply the technology for this dismantling line. According to Bosch, the system will be able to transport battery material of up to 150 kilograms per workpiece carrier at a speed of 18 metres per second. Also worth mentioning is the deep discharge: Within less than 15 minutes, eight lithium-ion batteries of electric cars can be automatically discharged. With the current manual process, it takes up to 24 hours before the batteries are deeply discharged.

In the future, a corresponding facility for black mass production is currently being planned at the Remondis subsidiary Retron, which already operates a European logistics concept for defective and critical lithium-ion batteries. Remondis is also part of the Rethmann Group.

“We’re combining the strengths of the two worlds of logistics and recycling at BLC in order to explore new horizons in battery recycling together,” says BLC Managing Director Florian Karlstedt. “Rhenus Automotive is certified to assemble vehicle parts on the production side and can make use of its expert knowledge in logistics as well as in handling batteries – and its infrastructure meets automobile standards.” Matthias Illing, also a BLC managing director, adds: “As a recycling company, TSR brings with it expertise in the fields of dismantling and refurbishing. TSR not only has the suitable business sites for this, but also the relevant permits for storing and reprocessing lithium-ion batteries.”

“Electromobility can only establish itself in the long term if sufficient raw materials are available for battery production,” says Stefan Hartung, Chairman of the Bosch Board of Management as supplier of the dismantling line. “Recycling plays a key role here, and helps place our output on a sustainable footing: we reuse what we use, and we recover raw materials.” At the Hannover Messe (17-21 April), Bosch will present industrial technology for battery recycling.

0 Comments