Vitesco adds separately excited synchronous drive option for the EMR4

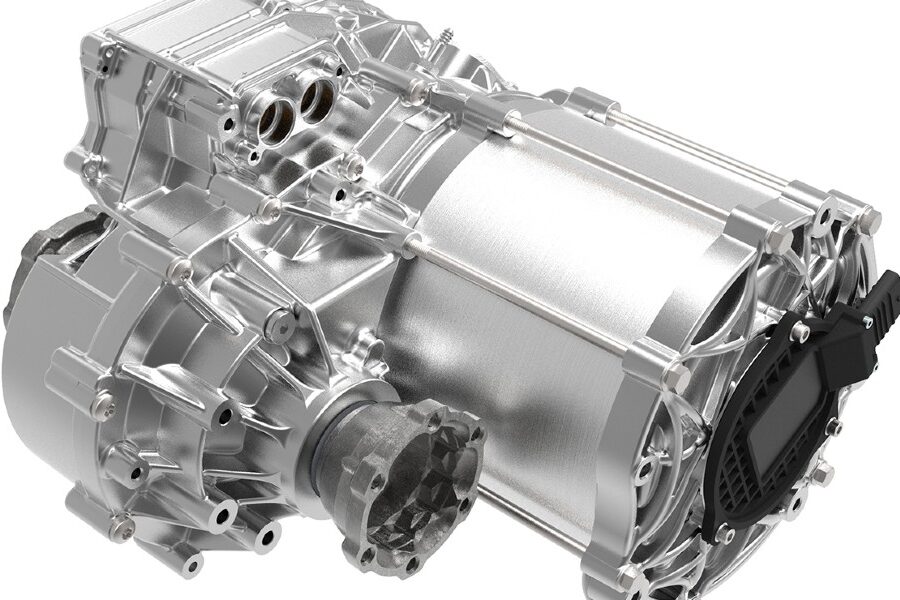

Vitesco Technologies added an additional option to the fourth generation of its fully integrated EMR4 electric axle drive platform: a new rotor without permanent magnets forms the heart of an externally excited synchronous electric machine that does not require rare earth materials.

The EMR4 (Electronics Motor Reducer) was presented by Vitesco in July 2021. Depending on customer requirements, the EMR4 can be designed as a permanently excited synchronous machine and cover the power spectrum from 80 to 230 kW. Compared to the EMR3, it is supposed to be 25 per cent lighter with the same power.

At the Vienna Motor Symposium 2023, the supplier has now showed another variant in which the PSM rotor with permanent magnets is replaced by a new rotor with electromagnets – the EMR4 thus becomes an EESM or externally excited synchronous machine. According to the Vitesco announcement, this reduces the costs for the rotor and also eliminates “the CO2 rucksack for the extraction and processing of the ores.”

The permanently excited electric motors were previously considered easier to manufacture than externally excited machines – since PSMs are also more efficient than asynchronous motors, for example, they are now widely used in electric cars. According to Vitesco, it has now “overcome decisive hurdles in the design of separately excited machines.” On the one hand, they have succeeded in achieving the same power class for both technologies “with targeted design changes,” which is why both options can use the same installation space.

The EESM rotor, whose coils have a “sophisticated winding technology,” should thus become an economical option. It should be able to show its advantages above all with more powerful electric motors, since with higher power requirements more magnets have to be installed in a PSM, which also increases the mass of the rotor and its price, for example. “Of course, the EESM option requires an additional module in the inverter to control the coils. Nevertheless, we are very close to an EESM plug-and-play solution,” says Gerd Rösel, Head of Innovation in the Electrification Solutions Division at Vitesco Technologies.

In addition to the cost savings for permanent magnets, greater security of supply and higher sustainability, this type of machine has other advantages: “When the vehicle is rolling in an energy-saving manner, the externally excited machine saves one watt-hour of electricity per kilometre because there is no permanent magnetic field braking the rotor,” Rösel continues, “thus reducing the power requirement of the drive by up to five per cent and without a mechanical disconnect clutch.”

“Top results in the sustainability and efficiency of electric cars will be achieved if the vehicle drive is optimally adjusted to the specific scenario,” says Thomas Stierle, Head of the Electrification Solutions Division at Vitesco Technologies. “The externally excited rotor without permanent magnets is a particularly sustainable option for our customers. The higher the performance requirements to the drive, the more economically attractive EESM technology becomes.”

0 Comments