JLR invests in Cyclic Materials

JLR is providing USD 2 million to Cyclic Materials through its investment company InMotion Ventures, extending the Series B financing round to USD 55 million. At the end of September 2024, Cyclic Materials had reported proceeds of USD 53 million from the financing round.

BMW – or more precisely the investment company BMW i Ventures – is one of the early shareholders and partners of Cyclic Materials and has been invested since 2023. With the current financing round, BDC Capital’s Climate Tech Fund, Hitachi Ventures, Zero Infinity Partners, Climate Investment and Microsoft’s Climate Innovation Fund have also invested in the Canadian recycling specialist. The latest cash injection from JLR brings the total capital raised in all financing rounds to USD 85 million.

Cyclic Materials says it will use the money to accelerate the expansion of its business in North America and Europe, improve its processing capabilities and refine its state-of-the-art recycling technologies.

“We are thrilled to welcome InMotion Ventures as a key investor, extending our Series B with an additional $2 million,” said Ahmad Ghahreman, CEO of Cyclic Materials. “Their investment highlights the surging importance of sustainable solutions in the automotive industry. We are honored to have one of the UK’s most active corporate funds as partners as we deploy our rare earth recycling infrastructure across North America and Europe.”

“Cyclic Materials is leading the way in creating a sustainable supply chain for rare earth elements and critical materials,” added Mike Smeed, Managing Director at InMotion Ventures. “Their innovative technologies address a vital need for rare earth magnets recycling, supporting the automotive industry’s transition toward a cleaner and more resilient future.”

Rare earths are currently among the least recycled metals, as it is difficult to separate the various magnetic materials in end-of-life products. Since its foundation in 2021, Cyclic Materials says it has already developed plants to prepare for commercial operation. Since 2023, the company has been able to recover rare earth magnets from scrap materials in a first demonstration plant using the proprietary ‘MagCycle’ process. This was followed last year by a demonstration plant (‘Hub100’) in Kingston, Canada, for the second process step to produce mixed rare earth oxides from the material.

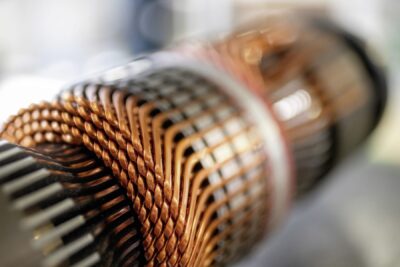

In the case of electromobility, the rare earth magnets to be recycled come from old motors, more precisely from the rotor of permanently excited synchronous machines. Permanent magnets, which usually contain rare earths, are installed there. However, Cyclic Materials is not limited to this one source of raw materials: Other material streams for rare earth magnets include wind turbines, MRI devices and electronic scrap, for example from data centres.

0 Comments