Fraunhofer IZM presents the ‘Dauerpower’ inverter

According to the Fraunhofer IZM, the inverter has a peak efficiency of 98.7 per cent. It offers a constant output (the literal translation of the German word ‘Dauerpower’) of approximately 600 kW or 815 horsepower, even over longer periods of time. That is, according to Fraunhofer, ‘1.5 times the power handled by today’s Diesel-powered heavy trucks.’

“The Dauerpower inverter can even handle 720 kW or 979 horsepower for short bursts,” the research institution adds. That will, in turn, set a new benchmark for high-end electric sports cars.’

The individual components of the Dauerpower inverter, first introduced last year, are small in size and ‘promises great modularity’, meaning that it can fit all kinds of applications.

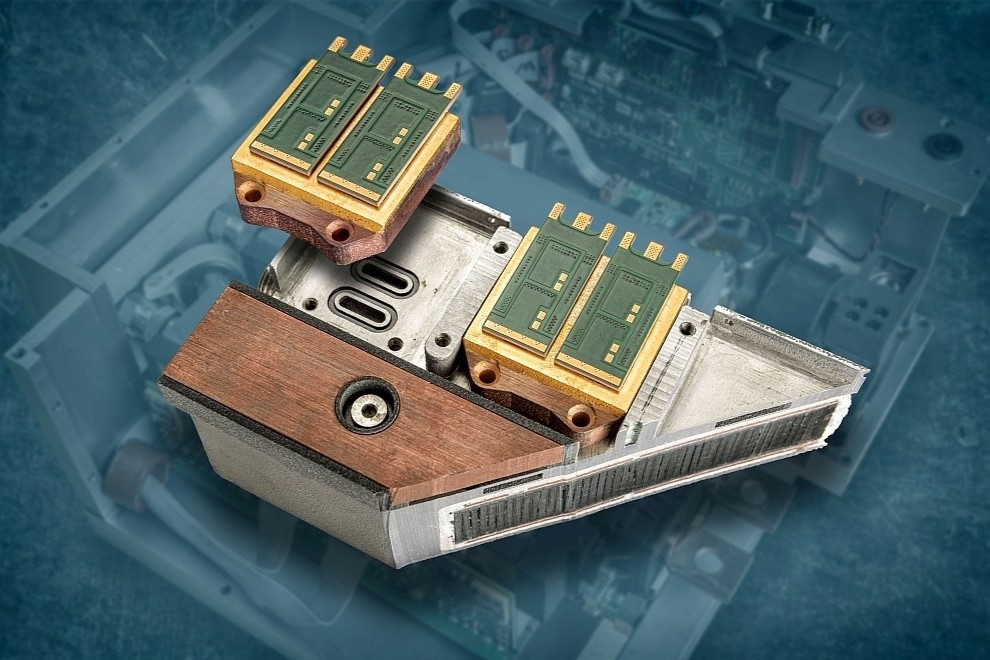

To handle this kind of output, the Dauerpower module relies on silicon carbide transistors. To process these, the Fraunhofer IZM uses an innovative prepackaging process, where two of these SiC transistors are applied directly to a ceramic substrate at the institute.

“Semiconductor embedding allows us to place the supply and return conductors far closer to each other and reduce leak inductance,“ said Dominik Seidenstücker, one of the lead scientists behind the innovation. “The module’s lower leak inductance allows faster switching transition. This, in turn, means even lower losses in the semiconductors.“

Cooling has also been optimised to further increase efficiency. The cooling element, which is made from copper, was 3D printed. It matches ‘the thermal requirements of the modules and ensures even heat dissipation’, the Fraunhofer explains. Critical components are then mounted onto the cooling system by silver sintering, ‘which again ensures their optimum thermal integration.’

The second aspect is made from aluminium, also using a 3D printer. It is where the heat is conducted away using water. The Fraunhofer IZM press release states that the system runs with 10 l of coolant per minute but loses only 150 millibars of pressure. The researchers conclude: “With cooling technology this advanced, the inverter remains in the optimum operating temperature even when under heavy load. One could say that the Dauerpower inverter knows how to keep its cool.”

0 Comments