US testing organisation UL Solutions opens battery testing laboratory in Aachen

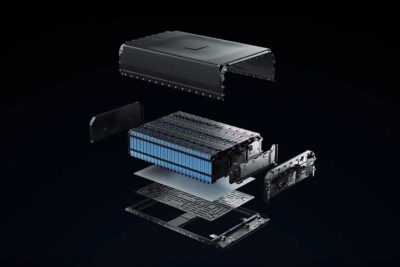

UL Solutions is an applied safety science company from the U.S. state of Illinois that provides testing, inspection and certification services. With the increasing demand for reliable battery testing, the new facility in Aachen is designed to evaluate electric vehicle and industrial batteries in the research and development phase of battery manufacturing. The facility will also offer comprehensive assessments of finished products to determine whether they meet safety and performance requirements.

“Our new location in Germany provides us with access to the region’s deep engineering talent and places us close to many of our key European customers,” said Jennifer Scanlon, President and CEO of UL Solutions. “We are meeting our customers where they are, helping the automotive and power sectors safely innovate in a world increasingly reliant on battery storage.”

Aachen has a significant amount of expertise in the field of batteries: the Chair of Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University is regarded as a leader in battery research and is involved in numerous projects. The battery recycling startup Cylib and the 2nd-life storage startup Voltfang are also based in Aachen.

The new lab replaces a smaller leased facility from UL Solutions, which was part of UL Solutions’ acquisition of Aachen-based battery testing and simulation company BatterieIngenieure in 2024. The acquisition has significantly expanded UL Solutions’ capacity to perform testing, advanced simulations and in-depth failure analyses of battery technologies. One of the key strengths of the new facility, according to UL Solutions, is the ability to estimate battery life – a critical factor for both manufacturers and consumers.

The battery testing laboratory is the first UL Solutions facility in the EU to focus exclusively on comprehensive battery testing. Specialised tests carefully examine resistance to a wide range of potential risks, hazards and adverse conditions, including abuse, degassing and thermal runaway. This is a chemical reaction that leads to a rapid rise in temperature and pressure in a battery and can cause fires and explosions.

0 Comments