CATL considers salt content in lithium-metal batteries to be elementary

The lithium metal batteries developed by CATL are said to have an energy density of 500 Wh/kg and a service life of 483 cycles – the latter is twice as much as previous prototypes, according to the company, which sees this as a “significant step toward commercial viability for applications like electric vehicles and electric aviation.” The researchers particularly focused on the electrolyte of the lithium metal battery and, more specifically, the concentration of LiFSI salt over the service life of the battery. More on this in a moment.

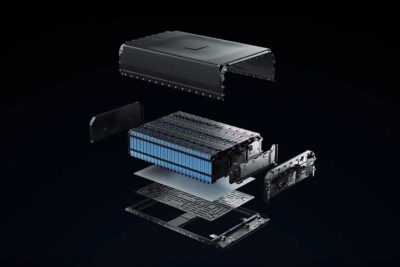

First of all, to put things in context: in lithium-metal batteries, the graphite-based anode material is replaced by lithium metal, which reduces the weight and volume of the anode and improves charging and discharging efficiency. Lithium-metal batteries offer a higher energy density and greater safety than lithium-ion batteries, but their commercialisation has so far failed due to their tendency to form dendrites, among other things. Corrosion within the battery and the scaling of production are also considered problems.

CATL has now published its findings in the specialist journal ‘Nature Nanotechnology’ under the long title ‘Application-driven design of non-aqueous electrolyte solutions through quantification of interfacial reactions in lithium metal batteries’. In it, the manufacturer explains that previous research work in this area has primarily focused on optimising the solvation structures or the solid-state electrolyte. “However, these batteries have long faced a trade-off between energy density and cycle life,” summarised CATL. So far, research has failed to precisely quantify the consumption of active lithium and electrolyte components during the cycle, which is why the reason for the rapid wear of lithium-metal batteries has so far remained unclear.

CATL claims to have developed and refined a number of analytical methods, which have now revealed that “contrary to previous assumptions, the dominant cause of cell failure is not solvent breakdown, dead lithium accumulation, or solvation environment disruption, but the continuous consumption of the electrolyte salt LiFSI.” This is 71 per cent depleted at the end of the battery’s service life. According to CATL, these results emphasise the need to “consider the durability of the electrolyte as a critical factor for long-lasting performance.”

The research took place at CATL’s 21C Lab – an in-house facility that focuses on the development of next-generation battery technologies. “We saw a valuable opportunity to bridge the gap between academic research and its practical application in commercial battery cells,” said Ouyang Chuying, co-president of research and development at CATL and deputy director of the 21C Lab. “Our findings underscore that LiFSI salt consumption and, importantly, overall salt concentration is a fundamental determinant of battery longevity.”

CATL claims to have invested a total of around 18.6 billion yuan (around 2.28 billion euros) in research and development in 2024. According to the battery company, it has more than 43,000 patents that have been granted or applied for worldwide.

However, there is strong competition in the research of lithium metal batteries. A team of researchers from the South Korean battery manufacturer LG Energy Solution and the Korea Advanced Institute of Science and Technology (KAIST) recently reported new progress in the development of such batteries, using a borate-pyran-based liquid electrolyte.

0 Comments