EU can secure rare earth supply by tapping low-risk deposits, study finds

Europe’s ambitious green energy transition relies heavily on Rare Earth Elements (REEs), critical components in permanent magnets for electric vehicles, wind turbines, and other clean technologies. However, the continent faces significant supply chain vulnerabilities, largely due to its heavy dependence on imports.

The global rare earth market is currently dominated by China, which recently restricted exports of these raw materials and still controls prices. This one-sided dependency poses significant risks for European manufacturers—not only economically but also geopolitically. A recent analysis conducted by the EU-funded REEsilience project offers new insight into mitigating these risks by exploring alternative, sustainable sources of REEs outside China.

Just a few deposits could secure EU supply

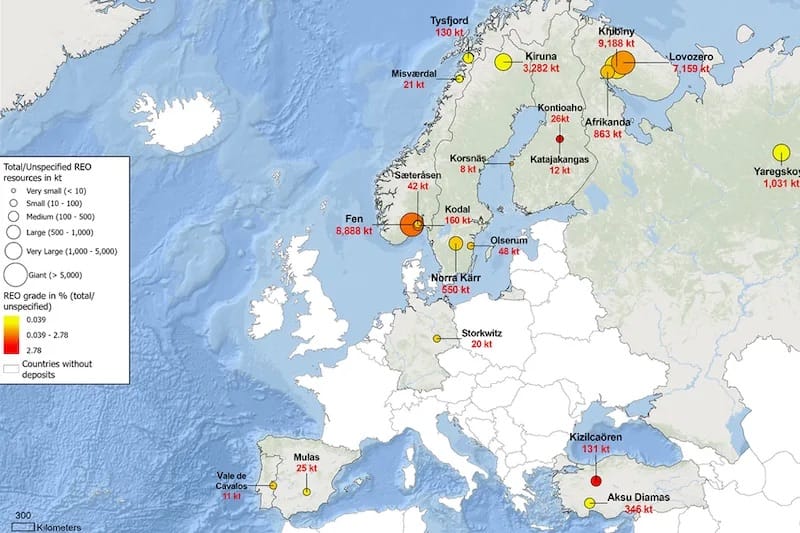

The REEsilience project, launched in 2022 and funded by the EU and UKRI, compiled an extensive inventory of 149 global rare earth deposits, assessing them based on environmental, social and governance (ESG) risk criteria. This holistic approach is aimed at identifying deposits that could be sustainably and securely developed to support Europe’s e-mobility and renewable energy goals.

“A critical mineral supply chain can only be truly resilient if it is also sustainable, in the broadest sense. That’s why it’s important to consider ESG aspects before exploiting new rare earth deposits,” said Maarten Koese from Leiden University.

The study highlights that many REE sources in ecologically sensitive regions, such as parts of Brazil, Central Africa, and Southeast Asia, pose considerable environmental and social risks. Conversely, deposits located in Western countries—such as Norway, Sweden, Finland, Canada, and Australia—present far lower ESG risks while offering favourable geological profiles. Norway’s Fen complex, for instance, was identified as a particularly promising site due to its scale and ore quality combined with a low ESG risk. Greenland also features prominently as a low-risk source with strong political ties to the EU.

Prof. Dr. Carlo Burkhardt, coordinator of REEsilience, emphasised the project’s comprehensive perspective: “For a supply chain that is both resilient and sustainable, it is of vital importance not to focus only on the technical part of magnet production but to see the bigger picture. Our REEsilience partners have done a tremendous job here.”

In addition to source mapping, the project developed a system dynamics model to simulate future supply chain scenarios, including potential disruptions and resilience strategies such as increased recycling and product lifetime extension. Dr.ir. Willem Auping of TU Delft noted, “Simulation modelling of uncertain systems like global metal supply chains can really help with understanding the future challenges of these systems and how to overcome them.” Early results suggest that while supply shocks could trigger price volatility, strategic resilience measures would substantially mitigate these impacts.

Focus on recycling, digitalisation and training

REEsilience’s work extends beyond raw material sourcing, encompassing advanced ICT-enabled production technologies, automation in magnet manufacturing, and enhanced recycling techniques, all aimed at strengthening Europe’s domestic capacity for rare earth magnet production. The project also focuses on training new experts to sustain innovation in this field. With the project’s conclusion slated for June 2026, further results are anticipated to solidify pathways toward a more resilient and sustainable European rare earth magnet supply chain.

This research underscores the potential for Europe to reduce its supply risks and environmental footprint by tapping into carefully selected low-risk rare earth deposits, combined with circular economy strategies and technological advancements. The findings provide critical insights for stakeholders across the e-mobility and renewable energy sectors as the continent pursues its net-zero ambitions.

0 Comments