TU Graz to protect EV batteries with wood-steel construction

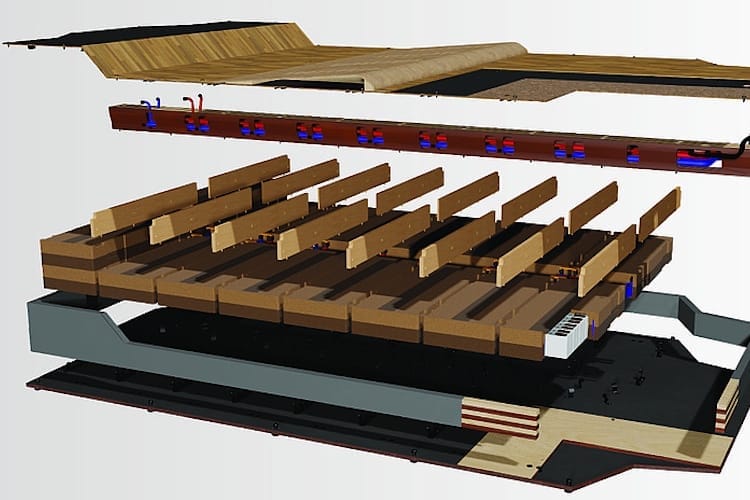

As part of the Bio!Lib project, a research team from the Institute of Vehicle Safety at TU Graz has achieved a remarkable step forward in sustainable vehicle construction. They developed a novel battery housing for electric cars made mainly of wood, thin sheet steel, and cork – materials with a significantly lower ecological footprint than conventional aluminium.

Battery housings are critical safety components. They must protect the battery from deformation in a crash and withstand high temperatures in the event of a fire. Until now, aluminium extrusion profiles have been the standard solution, though their production is extremely energy-intensive.

The new Bio!Lib housing completely eliminates aluminium, instead using a thin steel shell combined with a wood filling. In crash tests, this design delivered comparable performance to the aluminium battery housing of the Tesla Model S – particularly in the demanding pole impact test, where the vehicle hits a steel post head-on.

The use of wood is unexpected, given the particular fire risks associated with EV batteries. They can reach extremely high temperatures, with the danger of an uncontrolled thermal runaway. Wood, commonly associated with combustibility, initially appears unsuitable for such applications.

Charred cork provides protection

Yet the Bio!Lib team deliberately exploited the cellular structure of wood. Under pressure, the cells collapse and absorb energy, enhancing protection during collisions. Cork further improved fire resistance. “When cork is exposed to very high temperatures, it chars,” explains Florian Feist. “Carbonisation leads to a sharp drop in the already relatively low thermal conductivity, which protects the structures behind it.”

This effect goes beyond the protective capabilities of conventional materials. In a test at temperatures exceeding 1,300 degrees Celsius, the cork-insulated lid even outperformed the Tesla standard. On the side facing away from the fire, temperatures were about 100 degrees Celsius lower.

Positive environmental balance

An analysis conducted with the Wegener Centre at the University of Graz showed that the Bio!Lib housing outperforms conventional aluminium solutions in nearly all environmental categories – including primary energy demand, water consumption, and pollutant emissions. Only land use showed a disadvantage for wood.

In a follow-up project, the researchers plan to investigate whether lower-grade wood from thinning or recycling can be used. They also aim to further optimise the reuse of cork and the recyclability of the entire housing.

Using wood and cork in a battery housing may seem counterintuitive, given their association with flammability. However, through targeted material selection, structural design, and protective layers, the research team demonstrated that such a housing can be not only more sustainable but also safer than conventional solutions – a potential milestone for environmentally friendly e-mobility.

0 Comments