Fraunhofer enables real-time EV battery monitoring

The Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM has developed a method for real-time monitoring of lithium-ion batteries in electric vehicles. Using dynamic impedance spectroscopy, the system enables precise analysis of battery condition during live operation, enhancing safety, improving battery lifespan and enabling application in safety-critical sectors.

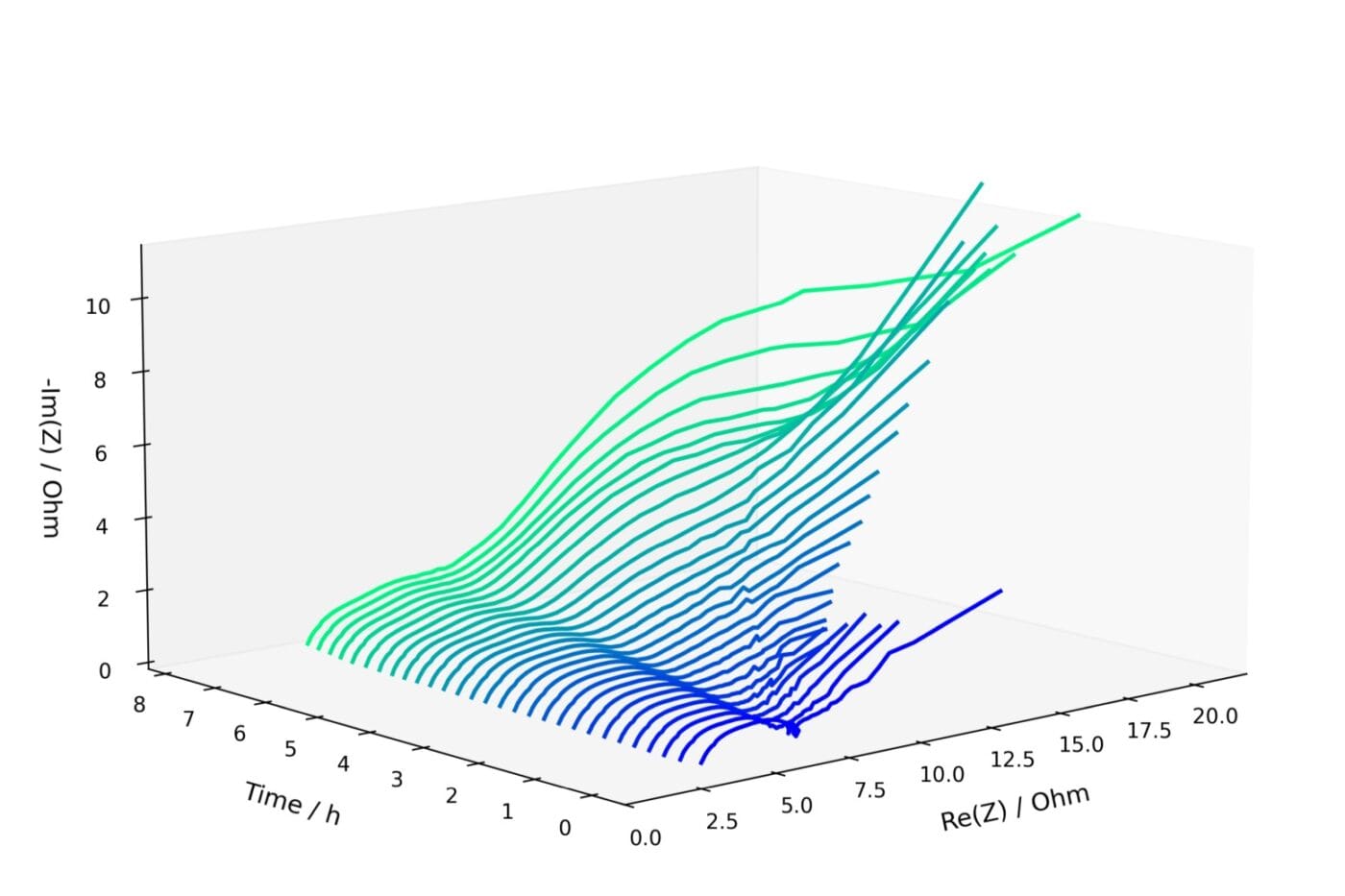

Impedance spectroscopy calculates a battery’s impedance, an indicator of state of charge (SoC), state of health (SoH) and internal safety, by analysing the ratio between current and voltage. Until now, this required the battery to be at rest and involved time-consuming measurement cycles, often taking up to 20 minutes. The new method developed under the leadership of Fabio La Mantia at Fraunhofer IFAM permits the same measurements in real time, even while the battery is in active use.

“First, dynamic impedance spectroscopy opens up new possibilities for optimising battery management, thereby extending the batteries’ lifespan. It also paves the way for these batteries to be used in safety-critical applications,” explains Hermann Pleteit, who heads up the project.

The method overlays the battery’s charging or discharging current with a multi-frequency test signal. Different frequencies probe various internal processes, and the response signals from current and voltage are sampled up to one million times per second. The resulting high-resolution data is processed instantly via integrated algorithms that reduce data volume without compromising key information.

The result is an immediate and detailed profile of the battery’s internal condition. This allows battery management systems to detect localised overheating events and respond in real time—disabling or throttling affected cells before damage occurs. As Pleteit explains, this eliminates reliance on external temperature sensors, which can be too slow to prevent thermal incidents.

Applications extend beyond electric vehicles. EV chargers can use the technology to optimise charging speeds depending on battery stress, allowing ultra-fast charging during short stops or wear-minimised charging over longer durations, the researchers state. The method also supports integration with renewable energy systems, enabling real-time control of battery modules for grid stability.

Fraunhofer IFAM anticipates potential in future aviation and maritime applications. “These kinds of systems could be used in eco-friendly electric aircraft, for example. This market is in its infancy right now. And the shipping industry is also signalling interest in the technology,” Pleteit noted.

The institute confirms that the method is compatible not only with today’s lithium-ion cells, but also with solid-state, sodium-ion, lithium-sulphur, and emerging battery chemistries, making it adaptable for future e-mobility platforms.

0 Comments