Helmholtz researchers look inside lithium-sulphur batteries

Lithium-sulphur batteries are expected to be lighter, cheaper and more sustainable than conventional lithium-ion batteries. Today’s lithium-ion batteries achieve energy densities of around 250 Wh/kg. Lithium-sulphur batteries, on the other hand, could achieve over 700 Wh/kg. This means that for the same amount of energy, the battery would be much lighter, an advantage for electric cars, drones, aircraft and space technology. Sulphur is also abundant as a raw material and replaces critical metals such as cobalt and nickel.

However, there are still hurdles that are slowing down this technology. For example, relatively little is known about the mechanisms that can lead to the failure of such Li-S batteries. A research team at the Helmholtz Centre Berlin (HZB) has now investigated this problem in more detail, focusing on the electrolyte.

For a battery to work, it needs a liquid electrolyte. This spreads between the electrodes and enables the transport of charged particles. If you want to build a particularly light battery, you have to reduce this liquid as much as possible. However, too little electrolyte means that some areas inside remain ‘dry’. This disrupts the chemical processes and can drastically shorten the service life.

‘It is crucial how the electrolyte wets the electrodes, penetrates their pores and distributes itself in the Li-S cells. However, due to the closed design of the batteries, it is extremely difficult to observe this without causing damage,’ says HZB chemist Prof. Dr. Yan Lu, who led the study.

Battery examined using neutron tomography

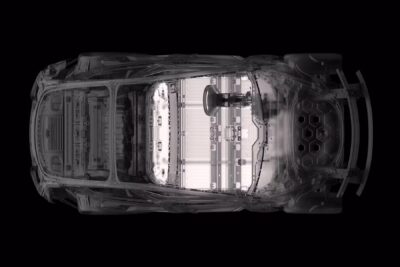

Normally, it is not possible to see how the electrolyte is distributed inside a closed battery – unless you cut it open and destroy it in the process. At best, such a procedure provides a snapshot. The researchers at HZB therefore used a special technique: neutron tomography. This method works similarly to a CT scan in a hospital – only instead of X-rays, neutrons are used. These penetrate materials to varying degrees, depending on the atoms they are composed of. Light elements such as lithium and hydrogen in the electrolyte can be visualised particularly well with this method.

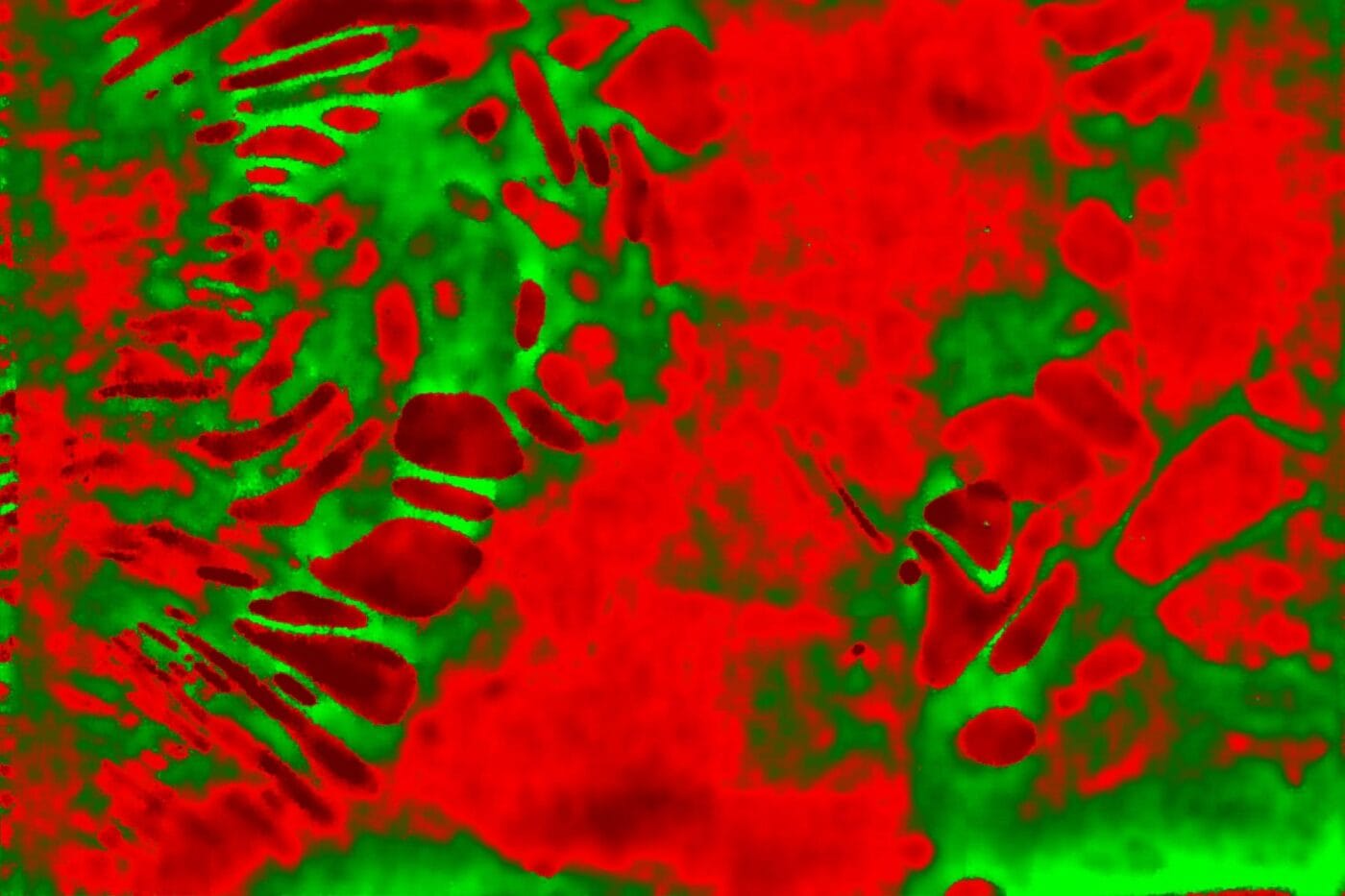

The team built special lithium-sulphur pouch cells with little electrolyte and examined them at the Laue-Langevin Institute in Grenoble. This allowed the researchers to observe in real time how the liquid distributes itself during charging and discharging. The recordings showed that at the beginning, there are often poorly wetted areas – comparable to dry spots in a sponge. If the battery is left to rest for a while, the electrolyte distributes itself more evenly. However, a very long rest period brings little improvement. Only when the battery is in operation, being charged or discharged, does the liquid distribute itself much better. This leads to more active use of the sulphur and an increase in capacity.

The process “enabled us to observe for the first time, how the liquid electrolyte behaves in real time and how the wetting changes locally in the different layers of a pouch cell over time. We gained some interesting insights from this,” said Yan Lu. Particularly exciting: the researchers discovered a periodic rhythm in wetting that is related to the formation and dissolution of sulphur compounds. This behaviour differs significantly from that of today’s lithium-ion batteries.

Targeted improvement of Li-S batteries

With these findings, the technology can now be improved in a more targeted manner. The aim is to build lithium-sulphur batteries that are lightweight, high-energy and durable. This could not only make electric vehicles more efficient but also open up new possibilities in aerospace. The project was supported by the German Federal Ministry of Education and Research and the EU.

There is already a lot of movement in the field of lithium-sulphur batteries: for example, the EU research project TALISSMAN has recently begun working on the development of innovative lithium-sulphur batteries for electric vehicles. And US battery developer Lyten, which is currently acquiring Swedish cell manufacturer Northvolt, already operates an automated pilot line for Li-S batteries in San Jose, California, which opened in May 2023. There, Lyten also produced its A-samples of its 6.5 Ah pouch cells, which were delivered to Stellantis and other car manufacturers in May 2024.

0 Comments