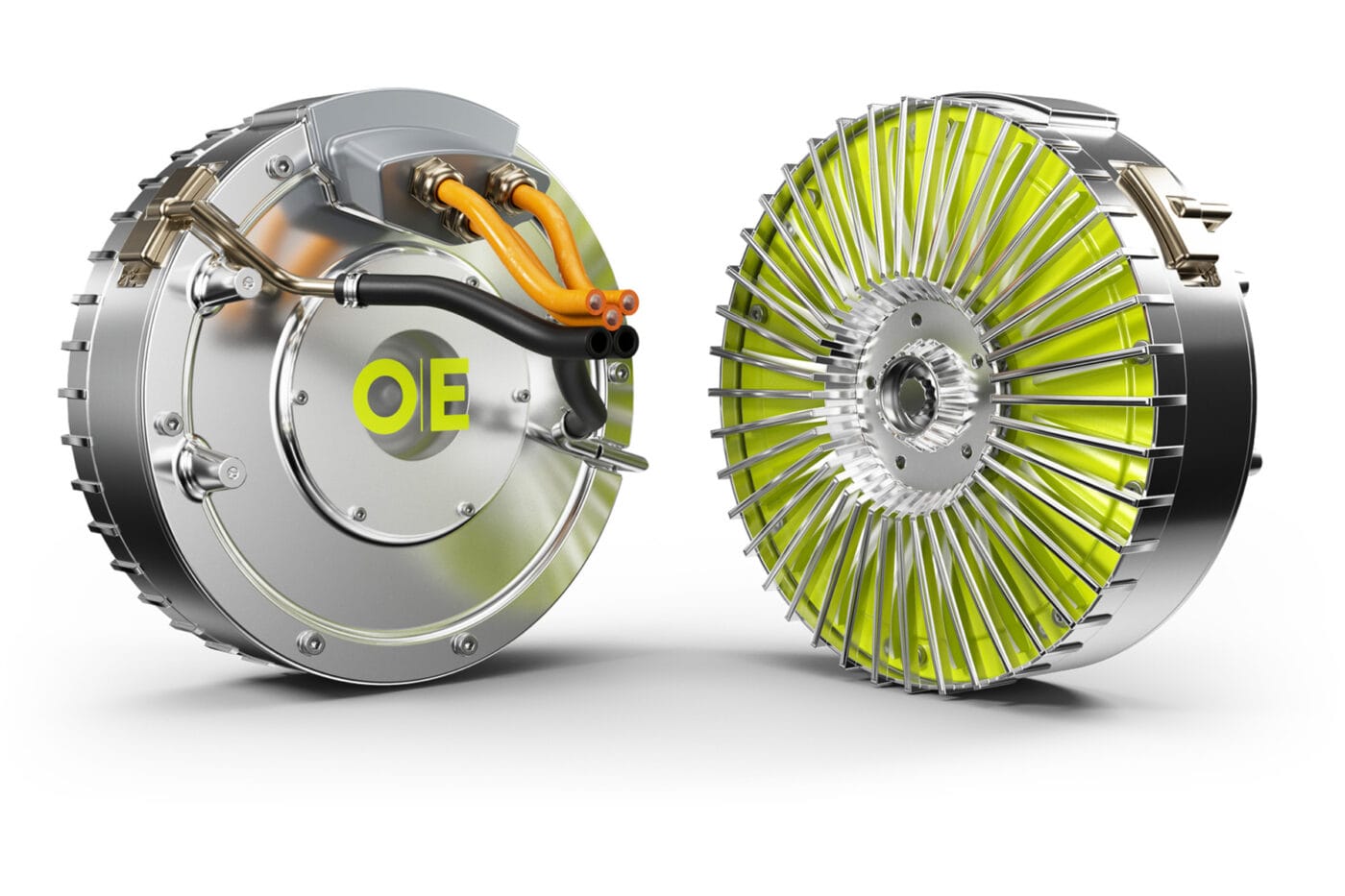

Orbis Electric presents axial flux motor ‘HaloDrive’

According to the announcement, the HaloDrive offers a high level of performance, efficiency and configurability with high torque and power density and improved thermal stability. The California-based company also provided some rudimentary figures: With a torque density of 100 Nm/kg, the HaloDrive is said to outperform conventional radial and axial flux designs and offer the torque of a V8 engine; however, Orbis does not provide specific figures for any particular variant of the HaloDrive.

The company also sees a major cost advantage, as a drive train is said to be up to 35 per cent cheaper than today’s widely used radial flux motors. The motor not only offers the aforementioned torque density, but also an efficiency of 97 per cent.

Axial flux motors differ from the familiar radial flux motors in the orientation of the magnetic field in the stator – once radially to the axis of rotation of the electric motor, once axially. On the one hand, this results in a different design; axial flux motors are often more like a disc with a significantly larger diameter than a comparable radial flux motor, but they are much shorter. Power and torque density are also usually higher, which is why axial flux motors are often lighter and more compact. So far, however, such motors have only been used in a few (hybrid) sports cars.

Orbis Electric also wants to utilise the more compact dimensions and is therefore praising the high level of flexibility when installing its Halo Drive. The unit has already been “piloted by leading passenger vehicle OEMs for in-wheel propulsion systems.” However, it should not only be suitable as a wheel hub motor, but can also be positioned in the drivetrain as P2, P3, P4 or P5. In hybrid drives, this refers to the installation positions of the electric motors, from the transmission input shaft (between the transmission and combustion engine), the transmission output through to the axle split without a mechanical connection between the electric motor and combustion engine.

It could also be used as a generator in stationary power generation, as well as in mobility, for example, in commercial vehicles. Here, the company specifically mentions the use of the drive unit for electric transport refrigeration units. “When replacing diesel-powered units, HaloDrive delivers up to 100% reduction in diesel refrigeration fuel consumption and emissions, and is 90% less expensive to operate. Installed on the driveshaft or an axle, the HaloDrive motor converts the truck’s braking energy into cost-saving electricity to power mobile refrigeration without dependency on plugging into the grid,” wrote Orbis Electric.

According to the press release, the HaloDrive is available immediately. However, Orbis Electric is still actively seeking Tier 1 production partners, as well as OEMs, fleets and industrial customers to accelerate its electrification and sustainability goals.

“Our vision with HaloDrive is to significantly advance how businesses transition to electrification by removing electric motor barriers such as deployment costs, material and manufacturability risks, and performance limitations,” said Chance Claxton, CEO of Orbis Electric. “With HaloDrive, we offer a high-performance axial flux motor that is not only highly efficient and powerful but also environmentally sustainable.”

This article was first published by Sebastian Schaal for electrive’s German edition.

14 Comments