Eberspächer subsidiary presents steel battery housing

The reason aluminium is usually preferred is obvious: weight. Aluminium is significantly lighter than steel, though not as strong. As a result, aluminium components need to be thicker and more robust to achieve the same strength – yet they remain lighter overall. However, aluminium comes with higher costs and greater energy demand in processing, which also leads to a higher CO2 footprint.

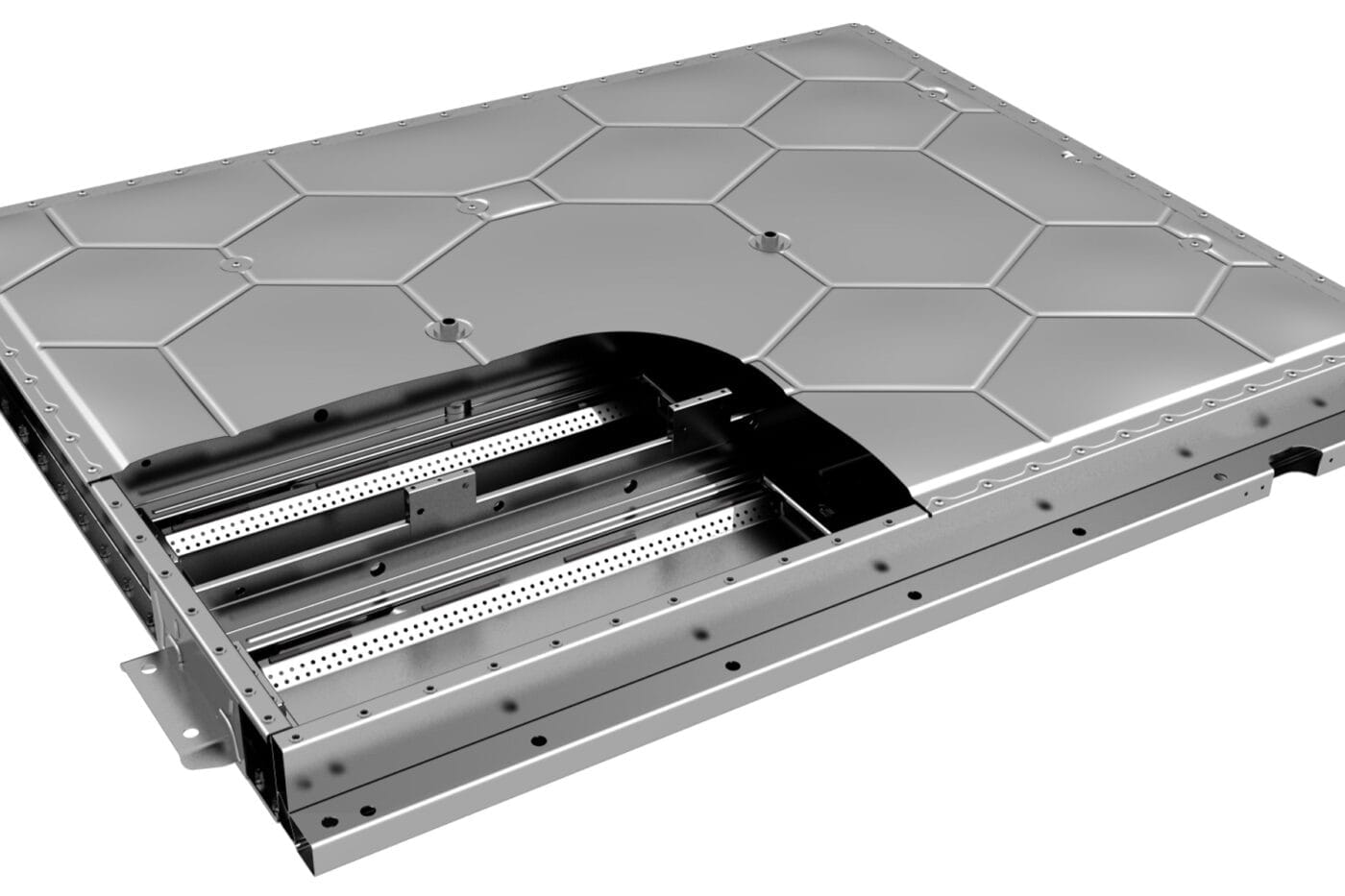

Purem by Eberspächer effectively reverses this argument, highlighting the advantages of steel. “Compared to aluminium, steel offers greater strength and makes lighter battery housings possible thanks to the use of thinner walls. Every gram counts, especially for high-performance batteries with a long operating scope—and is therefore an important competitive factor. In addition, production is not only more cost-effective, but also generates a smaller carbon footprint: The material can be produced using less carbon dioxide and is easier to recycle.”

The company’s statement does not include specific figures comparing steel and aluminium battery housings in terms of weight, cost, or CO2 footprint. Eberspächer does not plan to offer standardised housings but instead to develop them according to customer specifications. “The design is customised to accommodate the necessary ventilation ducts, the cable routing of the high voltage connections, or the arrangement of the individual battery modules,” the Esslingen-based company said.

In one area, however, there should be no compromise: safety. The battery housing must protect both the cells and the vehicle’s occupants in the event of an accident or battery damage. “Thanks to this material’s high strength and the corresponding design, the housing protects the battery in the event of a collision or from being hit by foreign objects.” Additionally, “precisely placed weld seams and special sealing solutions” are designed to ensure insulation of the battery modules.

The approach of using steel for battery housings is not entirely new. Back in 2021, engineering specialist IAV presented a steel-based battery concept with a focus on recycling. The same year, development service provider Bertrandt and Voestalpine introduced a platform for steel battery housings. More recently, TU Graz attracted attention with a hybrid wood-steel battery concept unveiled this summer.

Purem by Eberspächer plans to offer the steel battery housings for both battery-electric vehicles and plug-in hybrids. While the company is less represented in BEVs, it can supply two key components for PHEVs: Purem by Eberspächer specialises in exhaust aftertreatment systems and acoustic solutions and has built up extensive expertise in material processing and welding technologies through its exhaust business.

Around 7,500 people work for Purem by Eberspächer worldwide. In 2024, the division generated sales of approximately 4.7 billion euros within the Eberspächer Group.

This article was first published by Sebastian Schaal for electrive’s German edition.

0 Comments