Umicore establishes joint venture for the industrialisation of silicon anode material

The Belgian materials technology and recycling group Umicore has been developing silicon-carbon-based composite anode materials for electric car batteries for some time. After more than a decade of research and development, the company says the time has now come for commercialisation. Umicore’s anode technology centre in Olen, Belgium, is ready to transition to industrial-scale production, the group announced. HS Hyosung Advanced Materials, a materials specialist based in Seoul, is coming on board to support and co-finance this process.

Together, the two sides want to establish a joint venture called The Extra Mile, which will further develop the technology and expand Umicore’s existing production line in Olen into an industrial demonstration plant by the end of 2026. While HS Hyosung Advanced Materials will have an 80 per cent stake in the joint venture, Umicore says it will hold a minority stake of 20 per cent. Furthermore, “All of Umicore’s employees working for the anode materials activity will transfer to Extra Mile Materials and retain their employment terms and conditions,” Umicore announced. The transaction will therefore involve a significant restructuring. However, the deal still requires the usual regulatory approvals.

According to Umicore CEO Bart Sap, the joint venture is in line with the company’s strategy of entering into partnerships along the battery materials value chain. “Scaling and valorizing the anode material technology created by our teams in Belgium demonstrates our commitment to innovation.”

Geert Olbrechts, EVP & CTO of Umicore, added: “Umicore’s partnership with HS Hyosung Advanced Materials underscores the value of our extensive know-how and commitment to innovation in next-generation anode battery technologies in this fast-evolving market.”

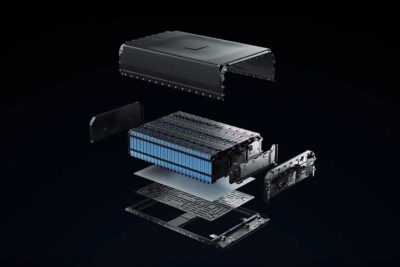

Umicore’s proprietary anode materials are currently in “qualification at multiple globally leading battery cell makers,” according to the company. Its proprietary silicon anode technology is protected by more than 30 patent families and is said to offer the electric vehicle industry “key benefits,” including higher energy density, greater range and faster charging, according to the company.

The fact that Umicore is only commercialising its proprietary technology as a minority shareholder speaks to the pressure the company is under. Just over a year ago, the Belgian company put plans for a cathode material factory in Loyalist, Canada, on hold. At the time, Umicore cited the need to adapt its investment plans to the ‘new market reality’ as the reason for this decision. The company went on to explain that the demand forecast for its battery materials had fallen sharply recently and that it now intended to utilise its existing production capacities before investing in new ones.

Based on this, the Belgian company announced a ‘thorough review’ of their battery materials business. The results of this review are likely to have been the deciding factor in the Belgian-Korean partnership in the field of anode materials.

umicore.com, hshyosungadvancedmaterials.com

This article was first published by Cora Werwitzke for electrive’s German edition.

0 Comments