Altilium secures UK funding for recycled EV battery materials

According to the company, its EcoAnode and EcoCathode processes will be used to show the “commercial potential and environmental benefits of integrating recycled materials into next-generation EVs.” The company’s proprietary EcoCathode process reportedly achieves recovery rates above 95% for critical raw materials such as lithium, nickel and cobalt, and was shown to produce cathode materials with high purity, consistency, and manufacturability.

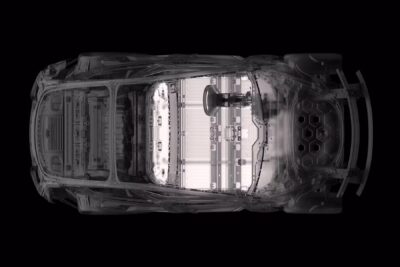

The project builds on a recent technology showcase of automotive-grade multilayer pouch cells and is designed to provide evidence of the carbon-saving potential of circular battery inputs within the UK automotive value chain. Specifically, Altilium and Jaguar Land Rover (JLR) showcased the UK’s first EV battery cells using recycled cathode and anode materials at Cenex Expo 2025. The cells were produced using cathode active material (CAM) recovered from end-of-life electric vehicle batteries at the company’s Devon facility.

Altilium says the programme will also support the UK’s Critical Minerals Strategy by reducing dependence on imported raw materials. The strategy was announced at the beginning of the week and includes plans to produce 10% of national mineral demand domestically and at least 50,000 tonnes of lithium by 2035.

This also comes as new EU Battery Regulations mandate minimum thresholds for recycled content in EV batteries. Altilium is scaling up its operations with its recently opened ACT 2 facility in Plymouth, the UK’s first commercial EV battery recycling site, and the upcoming ACT 3 plant, which will recover battery minerals from up to 24,000 vehicles annually.

0 Comments