Yasa develops axial flux in-wheel motor

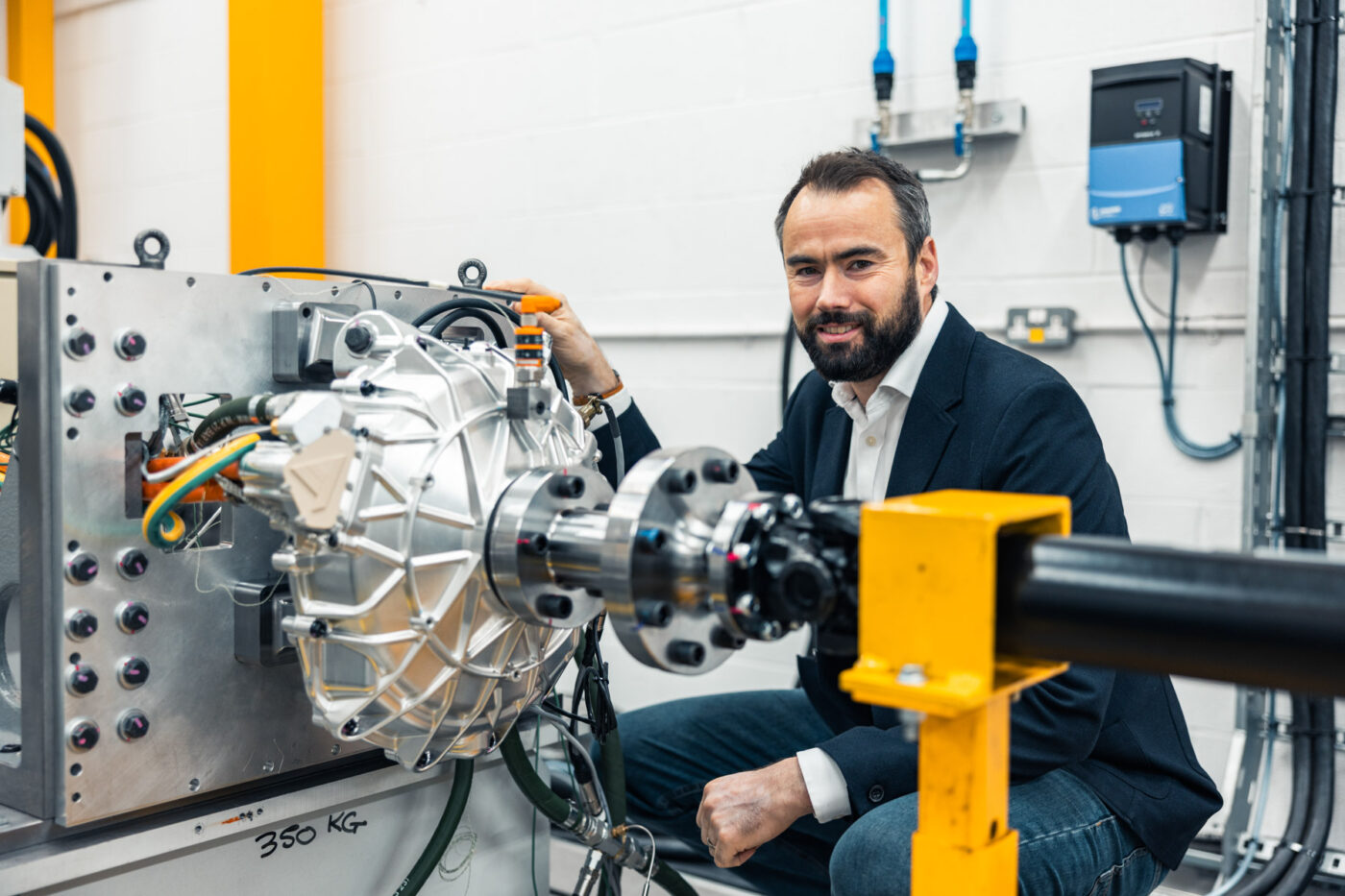

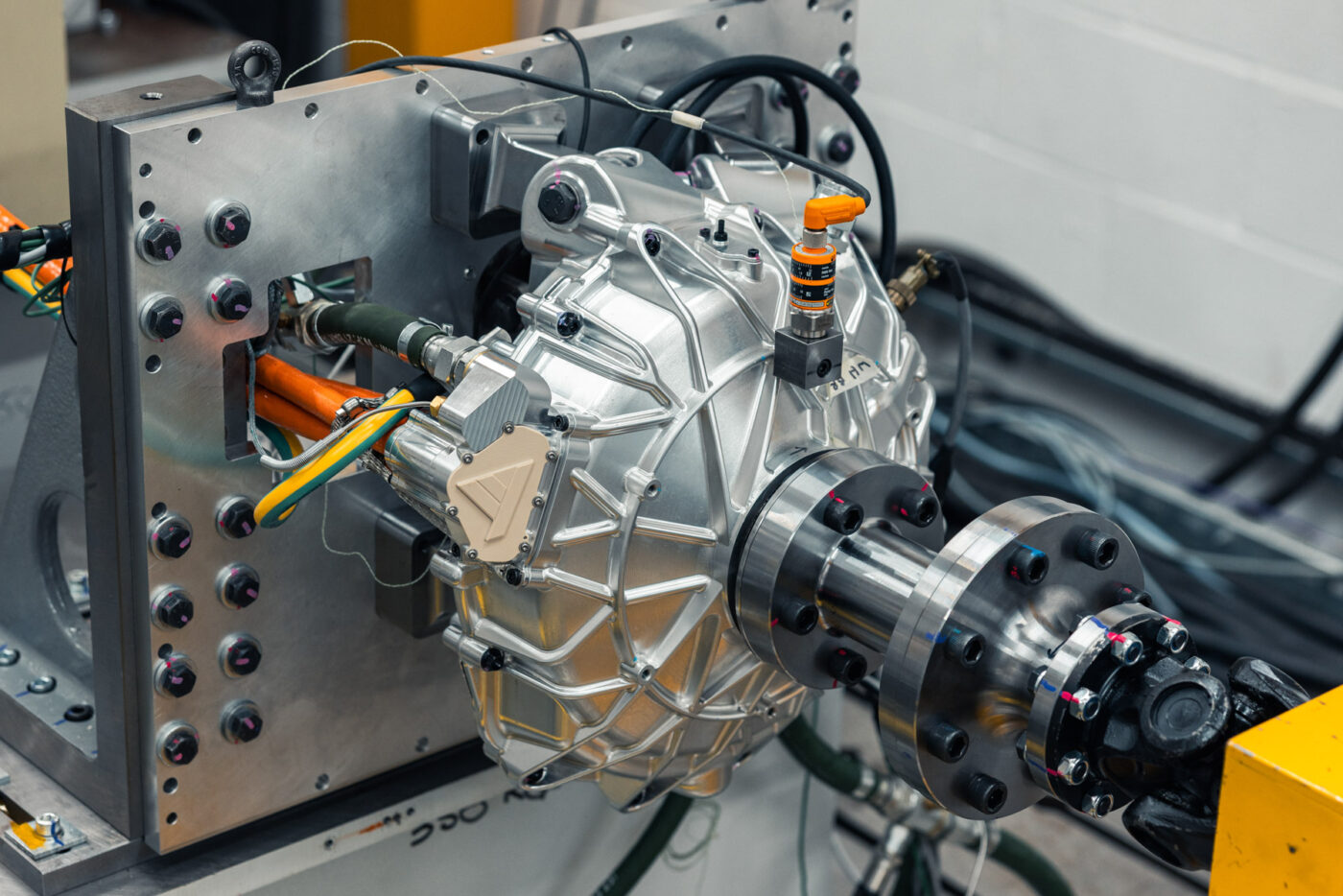

This axial flux motor achieves a short-term peak power output of 750 kW and is designed to deliver a continuous power output of between 350 and 400 kW. With an in-wheel drive, which is always installed in at least a pair, this is likely to provide more than enough power even for demanding applications.

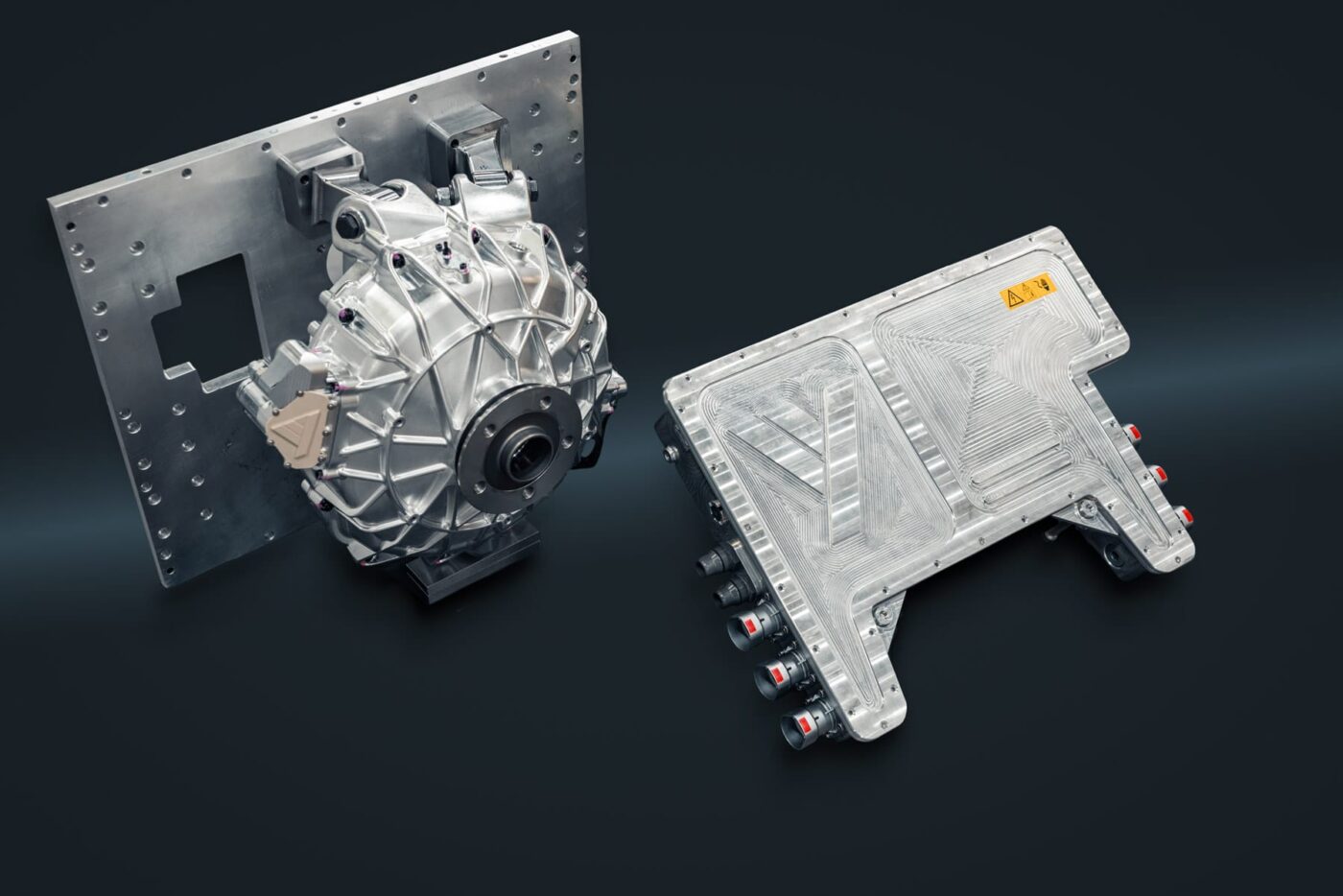

However, the innovation in this new in-wheel drive system is not solely the axial flux motor itself. Combined with a new 100 kW/kg inverter developed by Yasa, the system is expected to address ‘ all existing in-wheel motor issues and is set to unleash lighter, more efficient and higher performance EVs’, according to the company.

The inverter is designed to weigh 15 kilogrammes and deliver a power output of 1,500 kW, resulting in a power density of 100 kilowatts per kilogramme. Currently, the state-of-the-art benchmark for power electronics lies in the range of 50 to 70 kW/kg, Yasa states.

At present, however, the announced in-wheel drive remains a prototype. While Yasa anticipates ‘a whole host of game-changing benefits for future electric vehicles’ from the system, it may still be some time before a potential production model is realised. The company is currently withholding further details about the prototype, with additional information on the development of the in-wheel drive expected to be released in 2026.

So far, the British company has only revealed that the in-wheel drive, ‘thanks to its incredible regenerative performance’, could ‘dramatically downsize, or even potentially negate’ the need for conventional braking systems on the rear axle of an electric car. If components such as disc brakes and drive shafts are omitted, up to 200 kilogrammes of components could be saved, according to Yasa. If the vehicle’s basic structure is also optimised for in-wheel motors, the potential weight savings could reach approximately 500 kilogrammes.

While these figures are not directly comparable, other companies are also working in the same direction. The Munich-based startup DeepDrive has developed its own in-wheel drive using its dual-rotor technology and has even integrated it into test vehicles for demonstration purposes. DeepDrive also recognises the potential to downsize braking systems on the rear axle and uses the drum brake from MEB vehicles in its in-wheel drive, as a more powerful disc brake is not required on the rear axle. A test drive with the DeepDrive prototype demonstrated that preconceptions about in-wheel motors, such as increased noise or poorer handling due to unsprung masses, no longer necessarily apply to modern developments.

“In-wheel motors are the major challenge and opportunity for EVs, but until now, technology has been too heavy, limited in torque and not powerful enough,” said Tim Woolmer, YASA Founder and CTO. “This concept technology breakthrough is compact, powerful and light enough to be positioned inside the wheel of an EV, and it is the world’s first mass-neutral in-wheel motor, enabling up to 750kW (>1000bhp) per wheel. Combined with a new YASA-developed inverter, it results in a fully integrated prototype in-wheel electric vehicle powertrain, which will bring about a step change in weight reduction, performance and efficiency.”

Source: Information via email

This article was first published by Sebastian Schaal for electrive’s German version.

3 Comments