Astemo plans synchronous reluctance motor for 2030

Permanent magnet motors, or permanent magnet synchronous motors (PMSMs), are currently the standard in electric vehicles. This motor design, often abbreviated as PSM, offers high power density, making drivetrains smaller and lighter. Additionally, PMSMs are highly efficient, which reduces energy consumption and increases range. The drawback, however, is that the permanent magnets embedded in the rotor require rare earth elements such as neodymium to ensure temperature stability and strengthen the magnetic field. This makes these motors more expensive and leaves manufacturers dependent on supply chains from just a few countries, particularly China, which dominates the rare earth elements market.

Replacing permanent magnets is therefore a focus for numerous alternative concepts. BMW, for example, uses externally excited synchronous motors (EESMs), which incorporate an additional electromagnet in the rotor alongside the one in the stator, eliminating the need for rare earth elements. Astemo, the electric drivetrain joint venture between Honda and Hitachi, has opted for a different approach to significantly reduce “resource risks.”

Specifically, the Japanese company is developing an entire drivetrain system. The main drive motor, which is used continuously for propulsion, is equipped with magnets free of rare earth elements and delivers a power output of 180 kW. While rare-earth-free magnets, such as the ferrite magnets used by Astemo, are widely available, they possess only about a third, or even less, of the magnetic strength of conventional magnets. To match the performance of a traditional motor, the motor would therefore need to be roughly three times larger. The new 180 kW unit is not quite that large, but its active length is 30% greater than that of a 180 kW PSM using neodymium magnets.

New rotor core compensates for neodymium magnets

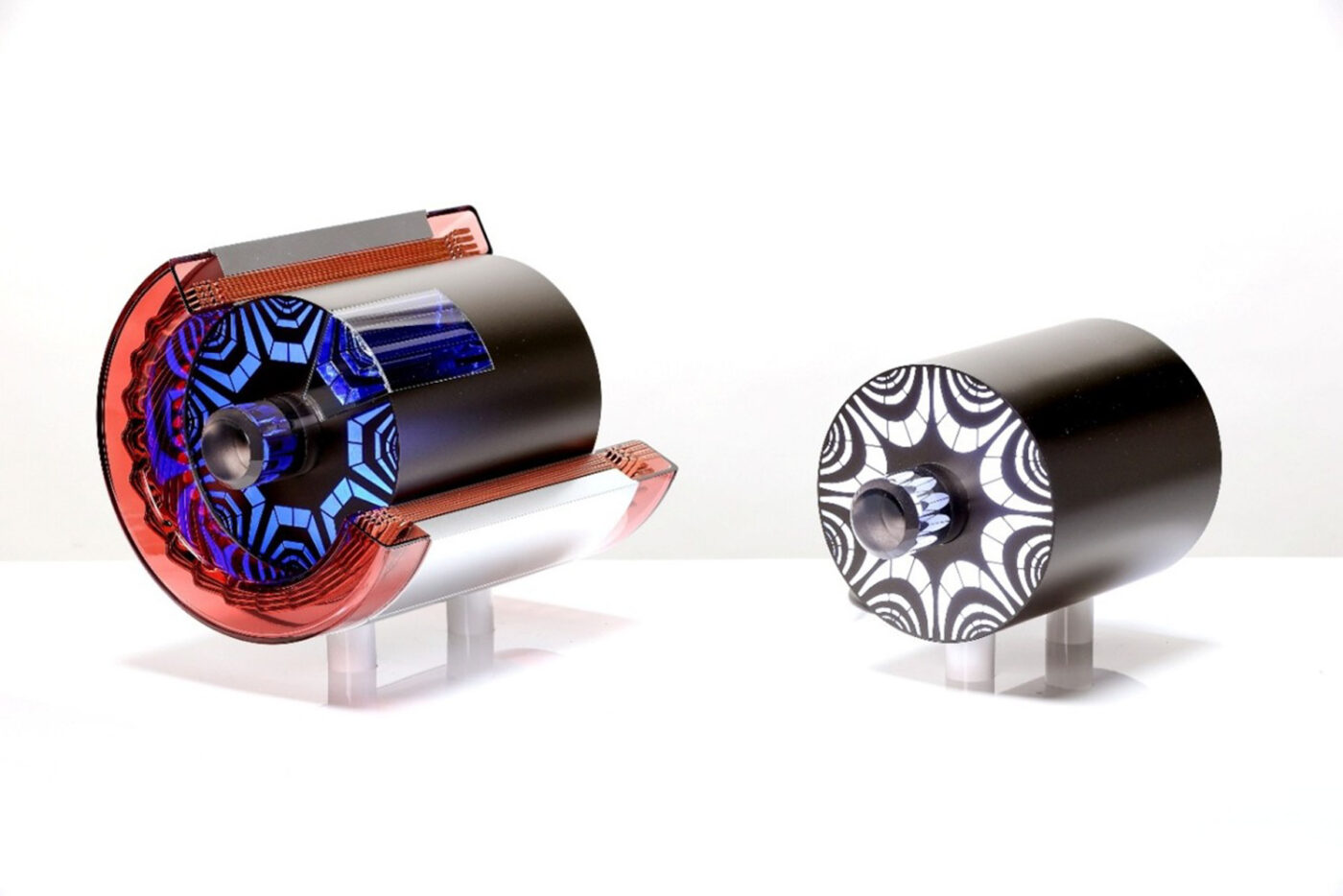

The fact that the new motor is “only” 30% longer—rather than 200%—than an equally powerful PSM is due to its specially developed rotor core. Instead of an iron core with neodymium magnets, Astemo has designed a so-called “multilayer flux structure” to compensate for the perceived disadvantages of ferrite magnets. The motor generates rotational force by utilising differences in magnetic reluctance arising from the shape of the rotor core. The special structure divides the path of magnetic force transmission into multiple layers. Simultaneously, “precisely controlling the current to form magnetic poles within the rotor core section, it can compensate for the powerful magnetic force generated by neodymium magnets,” the company explains.

However, the Japanese company also highlights why it will take time before the motor is ready for series production. “Forming magnetic poles in the rotor core requires a higher current flow through the stator coils (the stationary part of the motor). This presents a challenge, as the coils heat up more as a result,” Astemo states. To address this, the company has developed a structure in which the slots and ends of the coils are immersed in cooling oil. This approach “effectively reduces the additional heat generated in the motor,” according to the company.

Astemo has developed the synchronous reluctance motor in two variants. The first is a “magnet-assisted synchronous reluctance motor” with the aforementioned ferrite magnets and a power output of 180 kW. For the secondary drive in an all-wheel-drive system, a reluctance motor with a magnet-free rotor can be used. This features the same rotor core with a “multilayer flux structure” but without the ferrite magnets. In this configuration, the maximum power output is 135 kW, resulting in a combined system power of 315 kW.

“Since embedded magnets in the auxiliary drive can act as a braking force during coasting rotations of the main drive rotor, this would result in an energy loss,” Astemo explains. “Hence, the auxiliary drive operates only when needed for power assistance up to 135 kW, curbing the overall power consumption of the entire BEV drive system.” The practical application of synchronous reluctance motors is planned for 2030.

Incidentally, Astemo did not consider induction motors or externally excited motors, such as those used by BMW, as alternatives. While these motors do not require neodymium, the Japanese company identifies risks elsewhere in the supply chain. “However, since these use electromagnets to generate the rotor’s magnetic force, they require significant amounts of copper on the rotor. With the expanding adoption of renewable energy and electric vehicles, this presents a possible resource risk for induction and wound field motors with potential copper supply shortages,” Astemo states.

Source: Information via email (press release in German), astemo.com

0 Comments