ReDriveS: Schaeffler leads new project for recycling electric axle drives

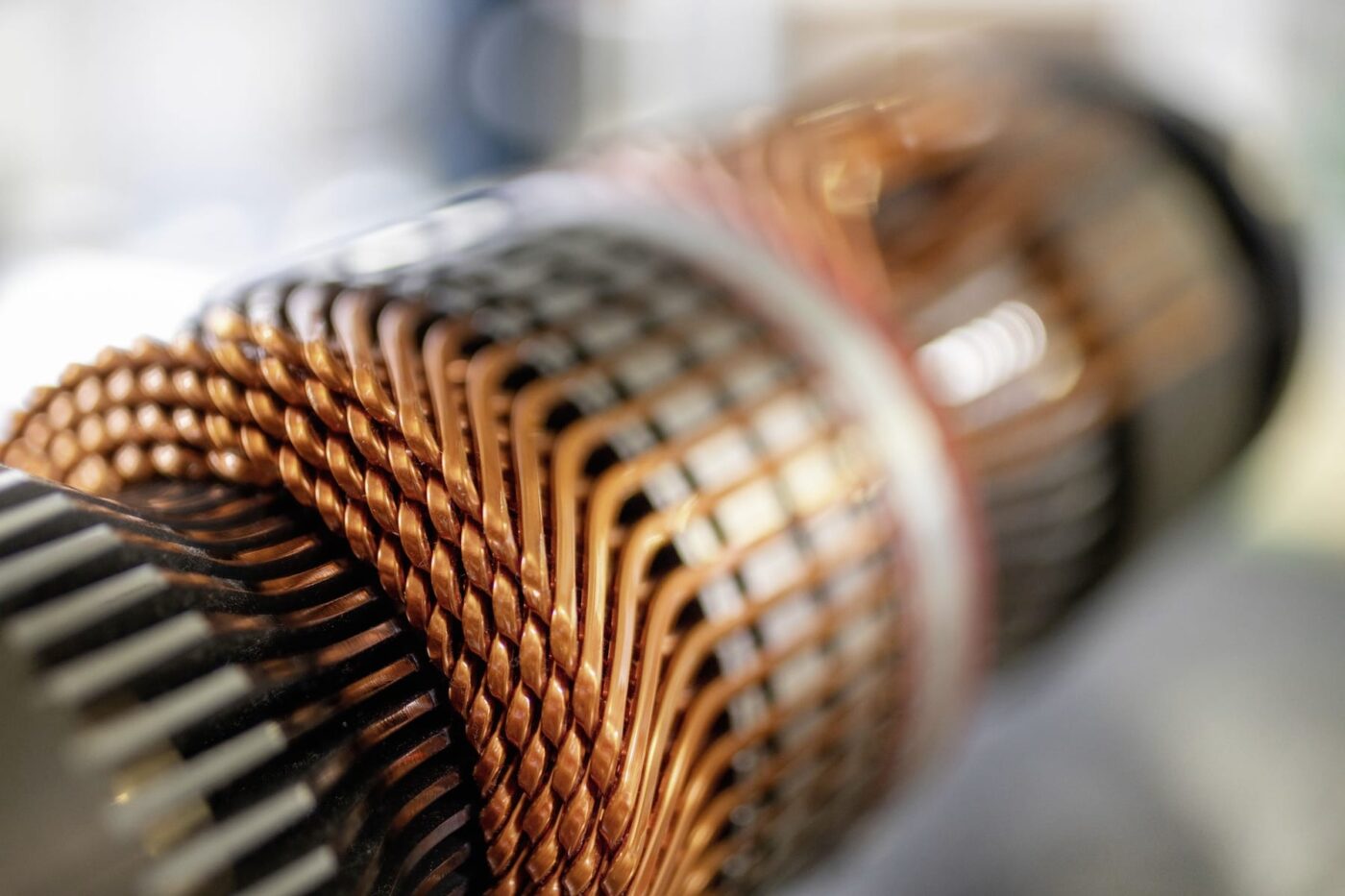

The electric axle drive in electric cars, often referred to as an e-axle, is an integrated unit comprising an electric motor, power electronics and a transmission, all compactly combined. It relies on rare-earth magnets (NdFeB) and other strategic materials—resources that are in scarce supply in Europe. Due to these supply chain challenges, as well as ecological considerations, it is becoming increasingly critical for suppliers and automotive manufacturers to recycle existing electric motors and e-axles at the end of their lifecycle. However, processes and facilities for this purpose remain lacking, although the UK recently opened its first large-scale operation for recycling rare-earth magnets from electric motors.

The new research project ReDriveS (Automated and Digitalised Circular Economy Solutions for Electric Axle Drive Systems), however, focuses not only on electric motors but on the entire e-axle. ReDriveS is supported by a budget of 25 million euros, of which over 16 million euros are provided by the Federal Ministry for Economic Affairs and Energy (BMWK).

The project aims to develop an industrial, automated and scalable recycling concept for electric axle drive systems—from robot-guided, non-destructive dismantling and innovative recycling processes to the use of digital data. This is intended to strengthen the resilience of the electromobility value chain. Additionally, ReDriveS will help meet future recycling quotas and reduce the CO₂ footprint of electric vehicles in Germany and Europe, which is generated along the supply chain.

Prof. Dr. Tim Hosenfeldt, Head of Central Technologies at Schaeffler, states: “With ReDriveS, we are leading a flagship project for the circular economy in electromobility as the consortium leader, together with the BMWK and strong partners. Our goal is to make electric axle drives significantly more resource-efficient through digital twins, automated dismantling and high-quality recycling—thereby securing raw materials and supply chains, reducing CO₂ emissions and strengthening Germany as a business location.”

In total, 25 partners are involved in the project, including AVL, Bosch, Circu Li-Ion, The Battery Lifecycle Company and Volkswagen, as well as various research institutions and universities such as the environmental agency Öko-Institut and the technical university TU Clausthal. The project is set to run for 36 months.

schaeffler.de, oeko.de (both in German)

0 Comments