BAM optimises anode of sodium-ion batteries

This anode is expected to significantly increase efficiency and storage capacity. The first charging process of a battery cell during production, known as formation, is a critical step, as it greatly influences the cell’s subsequent properties. During this initial charging process, boundary layers form on the anode’s surface as a reaction product of the anode material and the electrolyte. These layers are essential for the electrochemical processes during charging and discharging.

“During this process, electrolyte molecules decompose at the hard carbon anode and penetrate its pores,” BAM explains. “They occupy ‘empty spaces’ that are actually intended for the storage of sodium ions. This process only comes to a halt once a stable protective film has formed on the anode.” While this film protects the anode from further decomposition by the electrolyte, it consumes a portion of the storable energy, as it partially consists of sodium ions itself.

In other words, this boundary layer, which acts as a protective film, binds sodium ions, the charge carriers responsible for charge transport within the battery. In today’s widely used lithium-ion batteries, this is not a major issue, as their anodes are made of dense graphite, which allows the protective layer to form more easily. A lithium-ion battery achieves an efficiency of 90% without further intervention. “However, sodium cannot be stored in graphite,” BAM notes. “This type of battery therefore generally requires a different anode material, and so-called hard carbons have proven to be the best choice here – except for the aforementioned disadvantages during the first charging process.”

We realised that large storage capacities and efficient film formation cannot be achieved with sodium-ion batteries using a single material,” explains Tim-Patrick Fellinger, BAM expert for energy materials. “This is due to the fact that materials better suited for storage are more prone to losses during film formation.”

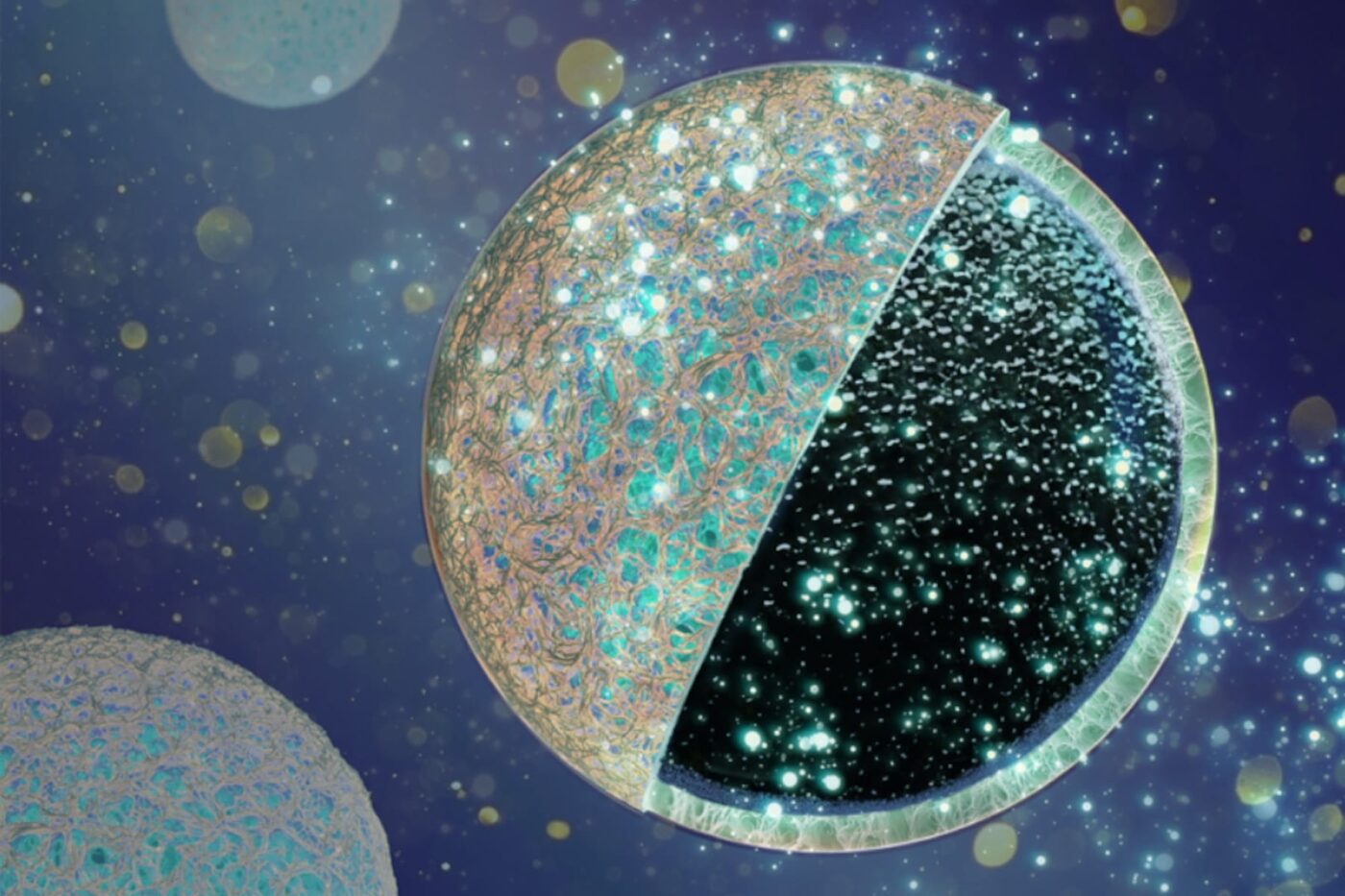

To overcome these disadvantages, the BAM team has ‘developed an innovative core-shell design for the anode.’ In this approach, a porous, sponge-like carbon structure forms the core of the anode, which is then coated with an ultra-thin layer (the shell) that acts as a filter. This layer is designed to allow the desired sodium ions for ion transport to pass through while keeping electrolyte molecules away from the carbon core. “This preserves the storage capacity of the anode and allows the battery to maintain its performance over many charging cycles,” BAM states. An additional advantage: the material is based on activated carbon, a cost-effective and environmentally friendly material, making the technology economically attractive as well.

The laboratory results are already promising: the materials developed in the study have achieved an initial efficiency of 82%, compared to just 18% without the coating. The BAM team expects further progress to be likely. The continued development of the anode material will take place at the Berlin Battery Lab (BBL), a collaboration between BAM, the Helmholtz-Zentrum Berlin, and Humboldt-Universität zu Berlin.

“Until now, advances in batteries have mainly been achieved through material innovations on the cathode side. Here, we are close to the theoretical limits. With anode materials, on the other hand, it is still completely uncertain where these limits lie and which innovations in material development – keyword: Advanced Materials – can be used to achieve further progress,” says Paul Appel from the team.

0 Comments