VW launches new EV architecture CEA for China into series production

Volkswagen recognised some time ago that to reverse its struggling business in China – where sales fell by 8 per cent overall in 2025 and by as much as 44 per cent for electric vehicles – it had to place even greater emphasis on the strategies of ‘local for local’ and, above all, ‘China Speed.’ To significantly accelerate innovation and time to market, VW entered into a close partnership with Xpeng, a Chinese electric vehicle pioneer, as early as 2023. Additionally, Volkswagen established the new VCTC development centre in Hefei, which is designed to independently develop and validate new vehicle projects and technologies for the Chinese market. This means decisions are made quickly on-site, without the need for coordination with Wolfsburg on every detail.

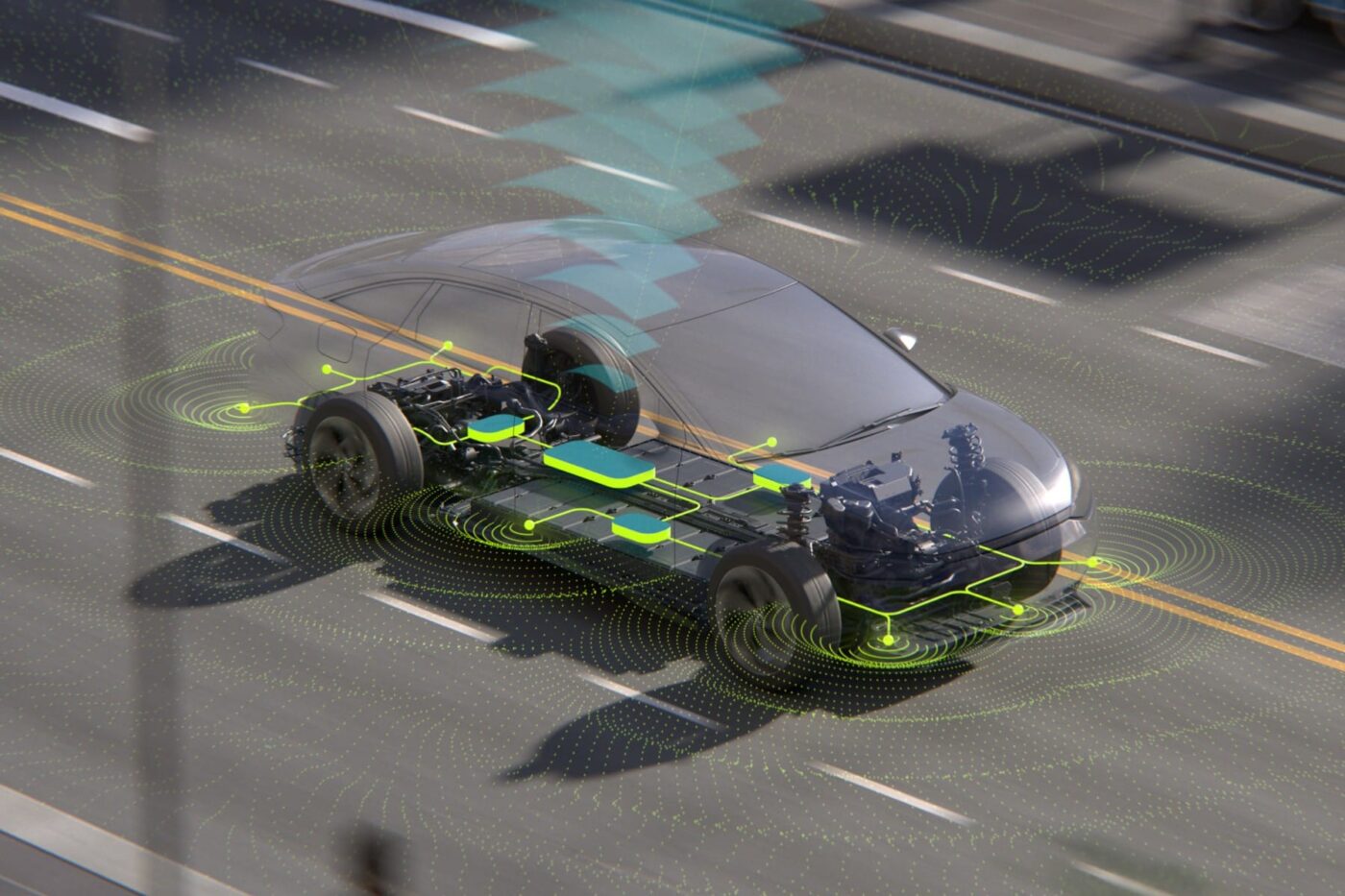

These measures are now paying off: the now series-ready China Electronic Architecture (CEA) is a zonal electronic and electrical (E/E) architecture featuring high-performance central computers. Essentially, it serves as the Chinese counterpart to the E/E architecture that VW is currently developing with Rivian for Western markets. The CEA will first be deployed in the new ID. UNYX 07, a 4.85-metre battery-electric saloon – approximately 11 centimetres shorter than the European ID.7 – powered by a 170 kW motor. After just 13 months of development, production commenced on 31 December 2025, as reported by the German Handelsblatt. An electric SUV, the ID. UNYX 08, based on Xpeng’s G9, is set to follow shortly.

According to the Volkswagen Group, the CEA reduces the number of electronic control units by around 30 per cent, significantly lowering system complexity. This provides a stable foundation for advanced AI cockpit functions, advanced driver-assistance systems (ADAS), and over-the-air updates for the entire software-defined vehicle (SDV). The architecture also enables the much-cited ‘China Speed:’ development cycles for new vehicles are expected to shorten by up to 30 per cent with the CEA. Development costs for new models could even be reduced by up to 50 per cent. Additionally, production costs for new electric vehicles in China are 50 per cent lower than in Germany, according to VCTC CEO Thomas Ulbrich. However, the latter is naturally also due to lower wages and exchange rate effects.

Volkswagen CEO Oliver Blume stated: “The start of production of our first zonal electronic architecture marks another milestone in our ‘In China, for China’ Strategy. The Volkswagen Group delivered – fast and reliably. In just 18 months, we have for the first time built a completely new, scalable electronic architecture from development all the way to series production – maintaining the high quality and safety standards that our customers expect from Volkswagen.”

Blume added that the CEA enables software-driven innovations across all powertrain types, accelerates the expansion of VW’s portfolio of intelligent connected vehicles in China, and is a key component of the Group’s global software strategy on ‘our software strategy towards our ambition of becoming a global automotive tech driver.’

Although the name China Electric Architecture initially suggests a focus on electric vehicles, VW emphasises that it is a platform for various powertrain types, including battery-electric vehicles, hybrids, and internal combustion engine models.

volkswagen-group.com, handelsblatt.com (in German)

0 Comments