Voltabox creates tech for free-form batteries

Battery system manufacturer Voltabox has presented a new technology concept to enable lithium-ion batteries to be produced in almost any conceivable free-form shape. The technology concept, called Flow-Shape-Design (FSD), is based on solidifying plastic materials to enclose the battery.

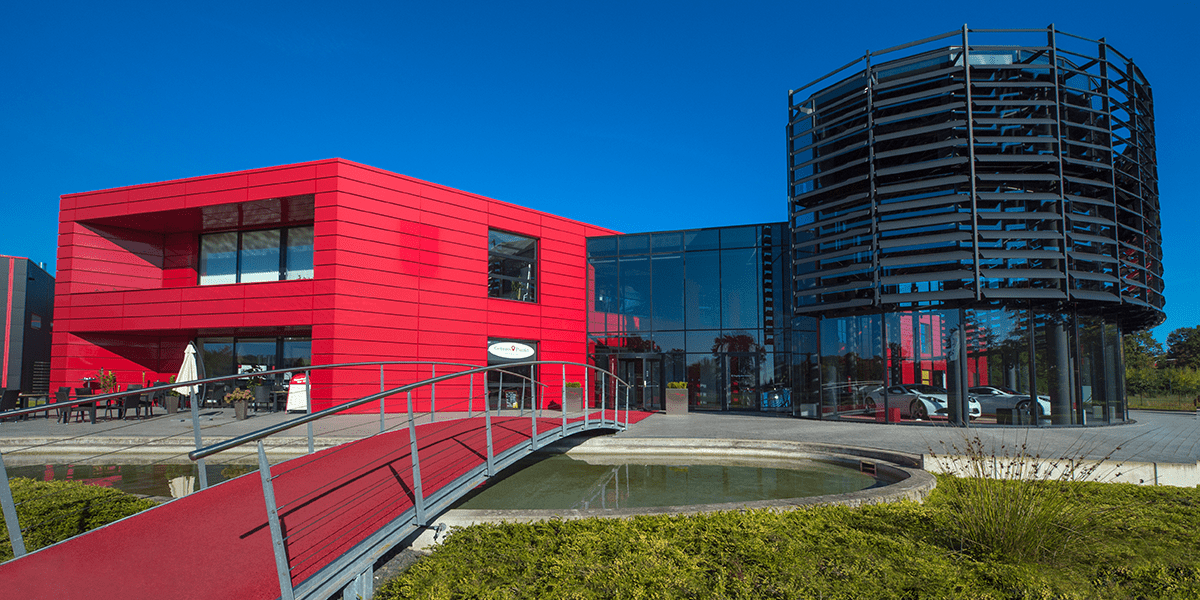

The idea behind this novel approach is to bring flexibility to the shaping of batteries while reducing weight at module and system-level and increasing cost efficiency. The company based in Delbrück, Germany, says that battery housings of the future will no longer have to consist of relatively heavy metal parts that are screwed or welded together. The flow-shape design based on self-solidifying and ultimately dimensionally stable plastic, meaning that the given installation space could be used many times more precisely. According to Voltabox, even completely new integration possibilities are conceivable, for example in defined areas of the body. A cell-to-system approach or, in the broadest sense, a cell-to-vehicle approach is possible.

The market launch of the new technology is scheduled for summer 2021 when Voltabox wants to start delivering its own FSD modules and customer-specific FSD battery systems. In addition, the company aims to spread this technology through licenses in selected markets. For this purpose, they have filed several patents and have already protected utility models and trademarks. Discussions on the use of the technology are now gradually being initiated with customers, according to the manufacturer, who also expects to issue the first licenses to battery manufacturers and OEMs starting next summer.

Voltabox believes that this technology has the potential to have a significant impact on the entire industry. The idea of relying on solidifying materials is borrowed from the aerospace industry, among others. “The method enables the use of all available cell types. Thanks to the special case concept and the material’s strongly energy-absorbing properties, the batteries are actually even more robust in terms of shock and vibration resistance,” says Voltabox. Different materials are always used depending on the specific requirements.

“Our conceptual innovation is extraordinary and disruptive because we have provided an answer to the key limiting factors for the use of lithium-ion battery technology, such as weight, system price and complex production methods,” says CFO Patrick Zabel. In addition, a significant reduction in the number of individual components, the use of low-cost materials and relatively simple manufacturing processes also make it possible to achieve significantly more attractive pricing compared to the current market level.

Company CEO Jürgen Pampel speaks of nothing less than a revolution in the lithium-ion battery industry: “This was only possible because we called into question every one of the current technical assumptions relating to battery design.” He added that the technology not only shows its strengths in the classic fields of application and those previously occupied by Voltabox. “The strengths of this technology will make themselves felt not only in the traditional fields of application which Voltabox has catered for to date. For boats, aircraft and stationary applications in particular, the advantages of Flow-Shape-Design are obvious,” says Pampel.

Voltabox is presenting its new approach to technology just at the end of a difficult year. The battery systems manufacturer already cashed in its growth targets for 2020 at the end of March in the face of the consequences of the Covid 19 pandemic. In May, Voltabox also presented a “comprehensive balance sheet adjustment” retrospectively for the 2019 financial statements. As a result, the Voltabox Group reported sales of 56.6 million euros for 2019 – well below the forecast of 70 to 80 million euros.

With reporting by Cora Werwitzke

1 Comment