Daimler considers earlier stop to combustion engines

Statements made by Daimler board member Markus Schäfer are now giving strength to the rumour Daimler could phase out the internal combustion engine well before the planned date of 2039. Schäfer did not, however, name a new “end date”.

Markus Schäfer is in charge of development on the board of Mercedes-Benz and of day-to-day business as COO on the Daimler board. Schäfer told the German publication Handelsblatt that everyone must recognise that the transformation of the vehicle industry towards electric drives may happen much faster than previously assumed. “In any case, we are preparing for an earlier changeover,” he said. He added that “in terms of products, there is no longer any rational reason to opt for a combustion engine in the near future”. Just last month the Daimler Group announced that Daimler’s passenger car and van divisions and the truck & bus businesses are each to form a single “pure play” company. Daimler Truck AG will be spun off and listed on the stock market as an independent company. Until now, the company has set 2039 as the target for a zero-emission new car fleet.

Schäfer says he believes that the speed of this transformation depends on how the stringency of the upcoming Euro 7 emissions standard. The EU Commission wants to present a concrete draft by the end of the year. “Depending on which regulations are applied in the end, the outlook for internal combustion vehicles can change dramatically – up to a scenario that makes it almost impossible to register internal combustion vehicles after 2025,” says Schäfer.

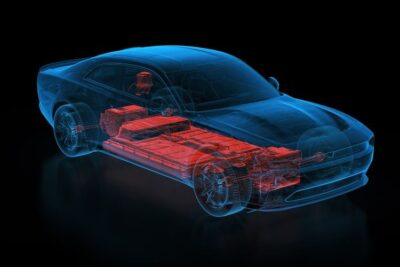

For carmakers, these stipulations obviously influence development and production planning. Daimler gave an indication of what this might look like last Friday: a new e-campus is being built at the main plant in Stuttgart-Untertürkheim, while crankshaft production there is being relocated to Jawor in Poland. Assembly lines for battery systems or components of the electric drivetrain (eATS) will gradually be established in other parts of the plant that previously produced petrol engines, transmissions and axles. From 2024, Daimler wants to produce the eATS itself and no longer buy it from suppliers such as ZF. This capacity is twice as much as the original plans.

When the e-campus was announced, the company left it open as to whether there would new combustion engines would be produced in Stuttgart. The company said last week that it wants to rely on the flexibility of the global production network. Schäfer has now let it be known that the ‘FAME’ engine family that was launched in 2016 will be discontinued in the future and that the latest models are the “final four”. The development expenditure for these units has been completed, the capacities built up. “This means that the bulk of the investments can now really go into electromobility,” says Schäfer.

While not flirting with an immediate end to internal combustion engines, the development director expects the variety of variants to decline significantly “by 40 per cent by 2025 and by 70 per cent by 2030”. “That is the minimum benchmark,” says Schäfer. “The change can also come much faster.”

Despite this view and the pilot production for lithium-ion cells announced on Friday, Schäfer continues to reject the mass production of cells demanded by the Daimler works council (worker’s union), saying that, “For us, it is not an option at the moment to build battery cells on a large scale ourselves, because the race for the best cell chemistry of the future is still completely open.” On its pilot plants for cell production, in Untertürkheim near Stuttgart, Daimler could indeed test the best combination of anode, cathode and electrolytes in the future and further deepen the understanding of the chemistry kit. “But I think it is too early to go into a massive investment for large-scale production now,” Schäfer said.

Schäfer refutes speculations that surfaced in February that the quality of cell samples at the company is poor saying that Farasis produces “innovative and high-performance battery cells”. Nevertheless, Schäfer hinted that the planned construction of a cell factory by Farasis in Bitterfeld-Wolfen in Saxony-Anhalt could be delayed. “As a rather young company, it makes sense for Farasis to focus on an industrialisation project first,” Schäfer said. Farasis currently only produces in China. Either way, Daimler sees its battery cell supply as secure, especially since the group also cooperates with the two South Korean corporations LG Chem and SKI Innovation.

With reporting by Sebastian Schaal, Germany

1 Comment