AUS: Tritium redesigns DC charger for mining operations

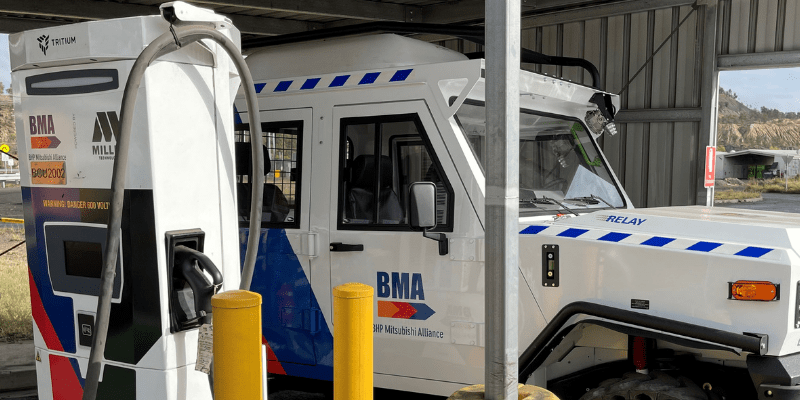

Australia’s high power charging specialist Tritium has teamed up with Miller Technologies to deliver a charging solution for mining operations. Miller just launched the Relay EV ready to operate underground and now runs the first project at Tesla supplier BHP in Queensland.

To comply with Australian mining standards, Tritium made modifications to its liquid-cooled fast charger. The RT175-S column with a 175kW output can provide 171 kilometres (106 miles) of range to an EV in as little as ten minutes, the company claims.

Miller Technologies’ Relay needs twenty minutes of charging to set it up for a ten-hour mining shift with two hours added through regenerative braking. According to Miller, the Relay was designed for light-duty operations after over a decade of R&D. The resulting EV can carry a two-ton payload and provides 1,550 newton-metre of torque. Miller adds it made everything in-house, including the rechargeable energy storage system (‘RESS’), which holds 43 kW in case of the Relay, according to the sell sheet online.

With Tritium on board, the company says the new EV now also features an “industry-first” hybrid charging system allowing for both off-board DC fast charging via CCS and on-board AC opportunity charging.

“As the only liquid-cooled, IP65-rated EV charging technology provider, Tritium is uniquely positioned to support the mining industry’s transition to electric vehicles through innovative charging technology that is sealed to protect against sediment, dust and moisture, and rated to operate in harsh conditions,” added Tritium CEO Jane Hunter.

The mining equipment specialist Miller also uses the Relay drive to electrify the BG 110-M, an underground motor grader. With a height of 1.80 m and an overall length without attachments of less than 7.40 m, Miller claims it can be operated in the world’s smallest mines.

The current project with Tritium is set at the BHP Mitsubishi Alliance mine in Queensland. BHP had recently made the news when Tesla chose to source nickel from the company’s mines in Western Australia as reported.

0 Comments