Bosch wants to build European supply chain for semiconductors

A new project called ‘Transform’ is dedicated to building a resilient European supply chain for silicon carbide semiconductor technology. Under the leadership of Bosch, 34 companies, universities and research institutions from seven European countries are working together on this project.

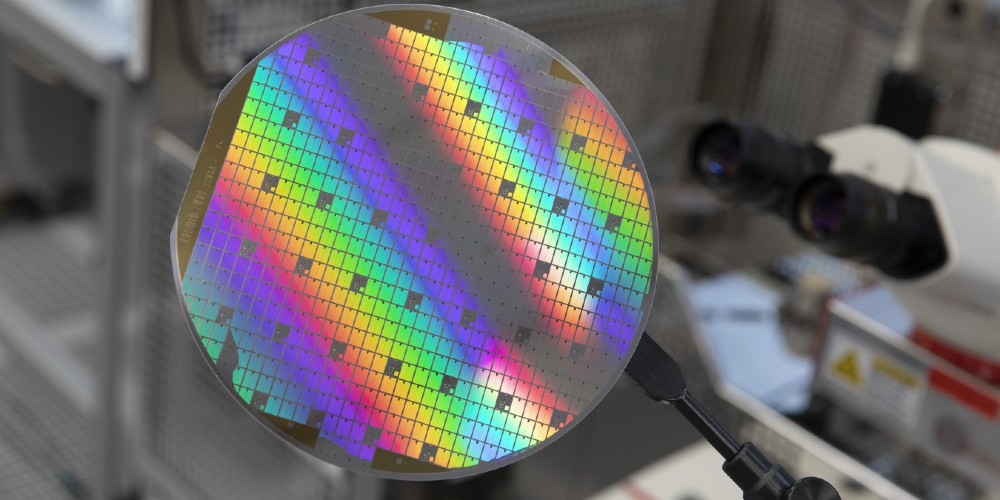

‘Transform’ stands for ‘Trusted European SiC Value Chain for a greener Economy’. Under the consortium leadership of Bosch, the project participants are dedicated to building a supply chain that extends from the starting materials and wafers to the SiC power semiconductors and complete power electronics. Their demand will grow strongly, especially in energy-intensive applications – from electric vehicle drives to charging stations and power supply.

In its statement, Bosch cites market research statistics from Yole, according to which the entire SiC market is expected to grow by an average of 30 percent each year to more than 2.5 billion US dollars by 2025. The funding project will therefore develop new SiC technologies as well as processes and methods for their production. In addition, the project participants want to ensure the availability of machinery and equipment for the production of substrates and wafers up to the power electronics of European suppliers.

Silicon carbide (SiC)-based technologies and the corresponding electronic components are considered a guarantee for efficient use of the available electrical energy. “The Transform project is intended to help Europe take a leading position in new technologies based on silicon carbide,” says Jens Fabrowsky, member of the Automotive Electronics Division Board of Management at Bosch. The funding project, which runs until 2024, focuses on a total of five applications in the automotive, industrial, renewable energy and agricultural sectors.

The following excursus on the importance of SiC technology: In many cases, the power electronics in electronic systems control the switching processes of the available energy and ensure that it is used as efficiently as possible. So-called power semiconductors ensure that the power electronics work in a particularly energy-efficient manner. While these chips are traditionally made of high-purity silicon, chips made of silicon carbide are now increasingly being used. These offer numerous advantages over silicon semiconductors: for example, they have better electrical conductivity. In addition, SiC enables faster switching processes and ensures that significantly less energy is lost in the form of heat.

Furthermore, power electronics with SiC components can be operated at significantly higher temperatures. As a result, the usually costly cooling can be reduced, which directly saves energy. Due to the higher electric field strength of silicon carbide, the components can also be dimensioned smaller – despite a higher efficiency in power conversion. Depending on the area of application, experts expect energy savings of up to 30 per cent compared to conventional silicon chips.

The Transform project was given a project budget of more than 89 million euros by the European Union. It brings together key players in the SiC value chain from Germany, France, Italy, Austria, Sweden, Spain and the Czech Republic, according to Bosch headquarters. The partner companies include Aixtron, Danfoss, EV Group, Premo, Saint-Gobain, Semikron, Soitec, STMicroelectronics and Valeo-Siemens Automotive. Participating scientific organisations are, for example, the Brno University of Technology, CEA Leti, Fraunhofer IISB and the University of Seville.

0 Comments