Eurocell to build battery ‘gigafactory’ in Europe

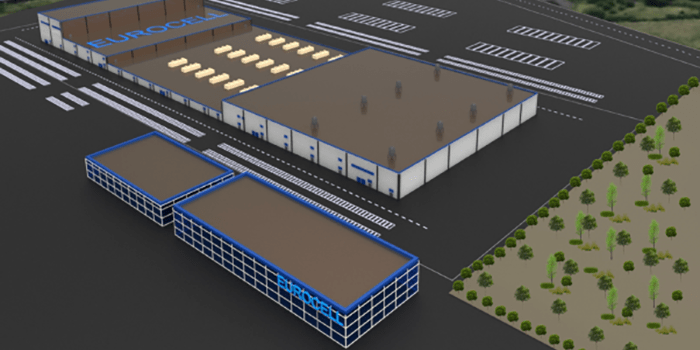

A British-Korean company called Eurocell has announced plans to build a ‘gigafactory’ for battery cells in Western Europe. This will also produce cells for electric cars and will be built in two phases with an initial investment of 600 million pounds.

The investment is equivalent to around 715 million euros. Eurocell highlights the promise that production should be possible in just 12 months thanks to the phased strategy and the “proven, production-ready technology.” In Europe, the production of battery cells that have been developed in Korea for existing customers is to begin as early as the beginning of 2023 with a plant capable of producing more than 40 million cells per year by 2025.

The company has not yet determined the location of its new European plant. Eurocell says it is in talks with sites in the United Kingdom, the Netherlands and Spain. The final choice would depend “heavily on getting the right level of support and investment from central government.”

Eurocell says the company’s new European home will benefit from the creation of hundreds of direct and indirect jobs, transferring vital skills from Korean battery experts and boosting the economy in a strategic sector crucial to achieving Europe’s net-zero ambitions.

“Eurocell in the UK is a new company, led by a highly experienced UK team and backed by our South Korean partner with decades of experience in electro-chemistry, making batteries at mass-scale and building the Gigafactories to produce them,” says Recardo Bruins, CEO of Eurocell EMEA. “Now we are planning to rapidly expand in Europe, supplying the energy storage and automotive industries with our market-leading technologies that last longer, perform better and are 100% safe. These products can be on the market in months, not years.”

Initially founded in South Korea in 2018, Eurocell self-designates its batteries as “UFC High Power” and “UFC High Energy,” with UFC standing for “Ultra-Fast Charging” respectively. Eurocell says it uses a nickel-manganese cathode and an LTO anode, which is made of lithium titanate. This material is known to enable high charge and discharge rates of up to 10C, as Eurocell also promises. One weakness of this technology so far has been its comparatively low energy density, which is why LTO batteries are used in electromobility, for example in buses, where the installation space of the batteries is less important than in passenger cars. Eurocell does not provide information on energy density.

It remains to be seen to what extent these cells are suitable for use in electric cars. Eurocell also raises the prospect of their use in stationary energy storage systems, where the energy density would presumably not be as much of an issue, but the long shelf life of the cells would be an advantage. “Their wide range of operating temperatures also makes them ideally suited to areas with extreme weather and without an existing grid network,” the company wrote.

European boss Bruins does not specify in the statement by when the location decision will be made. However, given the planned start of production in early 2023 and the lead time of twelve months, this should be soon.

With reporting by Sebastian Schaal, Germany.

Source: factory info via email, eurocell.co.kr (company), eurocell.co.kr (battery cell)

1 Comment