Polestar 5 to use bonded alumium chassis

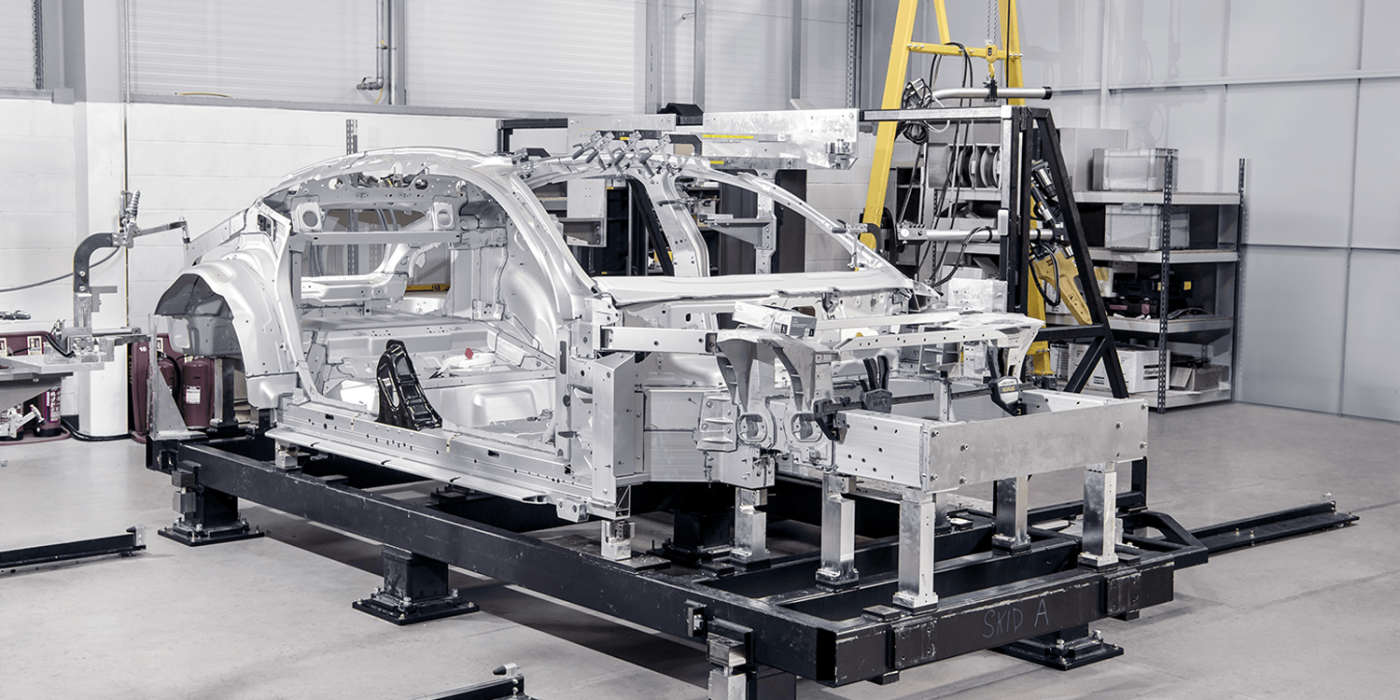

Polestar will use a new chassis made of bonded aluminium in the Polestar 5 announced for 2024. With a specially developed manufacturing process, the Swedish brand aims to avoid the previous disadvantages.

Among the advantages of bonded aluminium, Polestar cites “outstanding” performance and environmental benefits, as it is lightweight yet robust. However, the processing is difficult and time-consuming – and therefore expensive. As a result, other joining methods have been used for aluminium in high-volume production until now.

Polestar’s British research and development team, described by CEO Thomas Ingenlath as “one of Polestar’s greatest assets,” has developed a new, faster manufacturing process for processing bonded aluminium. According to Polestar, the process involves manufacturing both the body and the platform together. Thanks to the new materials and techniques, the body-in-white (complete platform and body) is expected to weigh less than those of smaller model classes, it said.

The lower weight is expected to increase the efficiency and range of the electric cars without lowering Volvo’s typical safety levels. As the stiffness can also be higher, Polestar expects the vehicles to be more dynamically responsive. For the Polestar 5, the brand announces torsional stiffness “superior to that of a conventional two-seater sports or super sports car.” How this will affect ride comfort is an open question.

There are currently 280 people employed at the Polestar development centre in Coventry, with the number set to rise to 500 in the coming months. So far, the team is primarily made up of former Formula 1, small-series and sports car engineers. These have brought their experience from elaborate prototype or low-volume production, where complex joining processes are more common than in high-volume production.

“Their mix of engineering and technological expertise enables us to develop advanced, light-weight sports car technology with a creative mindset and a spirit that embraces innovative engineering,” says Ingenlath. “This will set Polestar apart in the years to come.”

Although the Polestar 5 will not be launched until 2024, the Swedish company had already revealed the production design in November 2021. It is based on the Precept study but has some of the usual changes on the way to series production, such as the absence of doors that open in opposite directions. The goal of bringing as many elements of the Precept as possible into series production is reaffirmed by Polestar in the current announcement.

0 Comments