RWTH announces progress researching construction of hairpin stators

The Production Engineering of E-Mobility Components (PEM) chair at RWTH Aachen University has completed the ‘anfaHair’ research project after two years. The aim of the project was to make the production of new types of electric drives more efficient on an industrial scale.

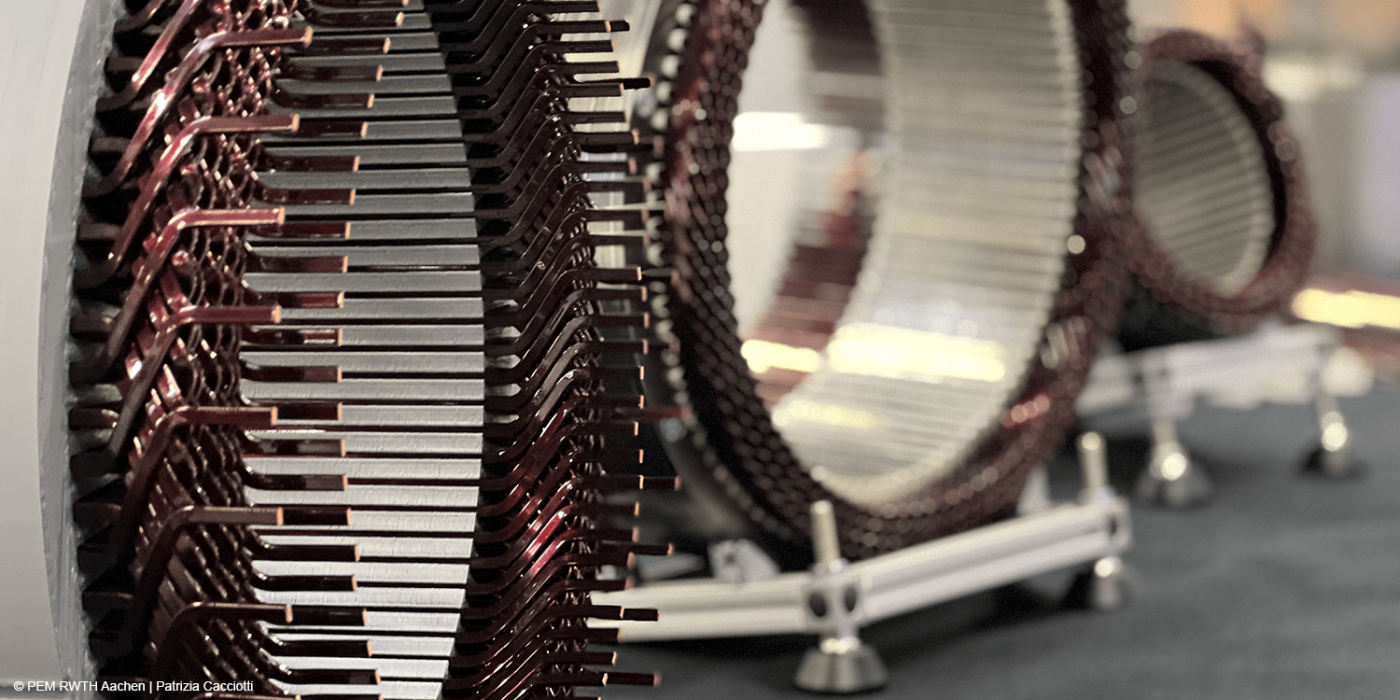

To this end, the PEM team, together with the Berlin-based mechanical engineering company Röscher, developed four potentially marketable joining technologies for the manufacturing process of hairpin stators as the component of electric motors that is crucial for their performance and efficiency. The ‘anfaHair’ project, short for “Initial Strength Joining in Hairpin Technology” or “Anfangsfestes Fügen in der Hairpin-Technologie” in German, ran from the beginning of February 2021 to the end of January 2023 and was funded by the German government.

“We have extensively tested the new joining processes and concretely demonstrated their applicability in hairpin stator production,” summarises PEM Chair Professor Achim Kampker. “In the process, we have identified technologically and economically viable use cases for all processes.” The hairpin design with its plug-in coil structure made of solid copper wires is increasingly replacing conventional wire winding techniques.

In the corresponding process chain, the focus is currently on laser contacting of the numerous copper ends, but according to PEM, welding defects in series production have so far led to high reject rates and low system efficiency. The research project should decouple the two processes of geometric weld preparation and subsequent contacting and produce an exact joining procedure. “Subsequently, the procedure should be integrated into the hairpin process chain, where it should enable a reproducible and dimensionally stable alignment of the copper wires prior to welding and thus increase both the quality and the stability of the overall process chain,” the PEM states in a statement.

The results from the ‘anfaHair’ project are now to be further utilised in the form of scientific and industrial projects. Project partner Röscher is specifically planning to further develop the prototype station set up in the course of the project for industrial and serial applications. Initial enquiries from other companies have already been received, they say. In parallel, the applicability of the system is being tested in related areas.

RWTH Aachen University is involved with stators on various levels. For example, the PEM team is also involved in the HaPiPro² project, which aims to flexibly manufacture stator variants with hairpin windings on a production system.

1 Comment