Metis Engineering presents new battery safety system

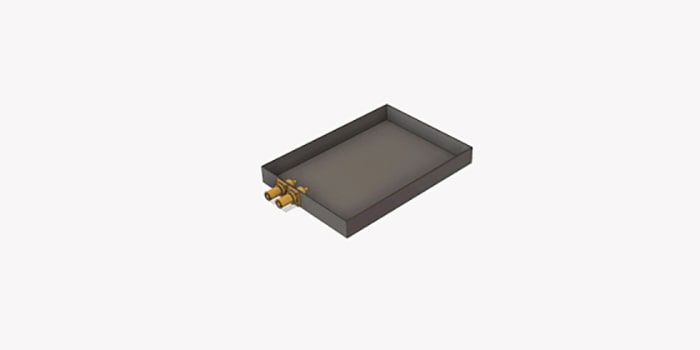

The UK-based firm Metis Engineering presented ‘Cell Guard’, a new battery safety sensor that aims to revolutionise battery health monitoring for electric vehicles (EVs) and Energy Storage Systems (ESS).

According to Metis, the Cell Guard sensor provides “unrivalled accurate and detailed information on the health of a lithium-ion battery pack to improve longevity”, as well as being capable of detecting cell venting, which is an early sign of battery failure vastly reducing the risk of thermal runaway. Furthermore, next to the traditionally monitored temperature and voltage sensors, “Cell Guard monitors a range of environmental parameters required to ensure that the battery continues to operate in optimum conditions, including VOCs, Pressure change, Humidity, Dew point and has an optional Accelerometer to record shock loads.”

If an issue is then detected with the battery, the system will raise a warning to alert the driver that cell venting has occurred. The sensor can also trigger the process to cut the circuit to the battery pack, giving it the opportunity to cool down with the objective of preventing thermal runaway.

“As cells age the chance of one in a pack of hundreds or thousands having a fault increases significantly. The early detection of cell venting is vital to the safety of the vehicle’s passengers and everything in the immediate proximity,” said Joe Holdsworth, Managing Director at Metis Engineering. “Our sensor offers far greater accuracy and data than current battery cell monitoring equivalents, and at a much lower cost, up to ten times cheaper than alternatives.”

Source: Info via email

1 Comment