BASF subsidiary and Advent Technologies set up European FC supply chain

BASF Environmental Catalyst and Metal Solutions have signed an agreement with Advent Technologies to establish a full-loop supply chain for fuel cell components in Europe. They will also work together on their latest developments.

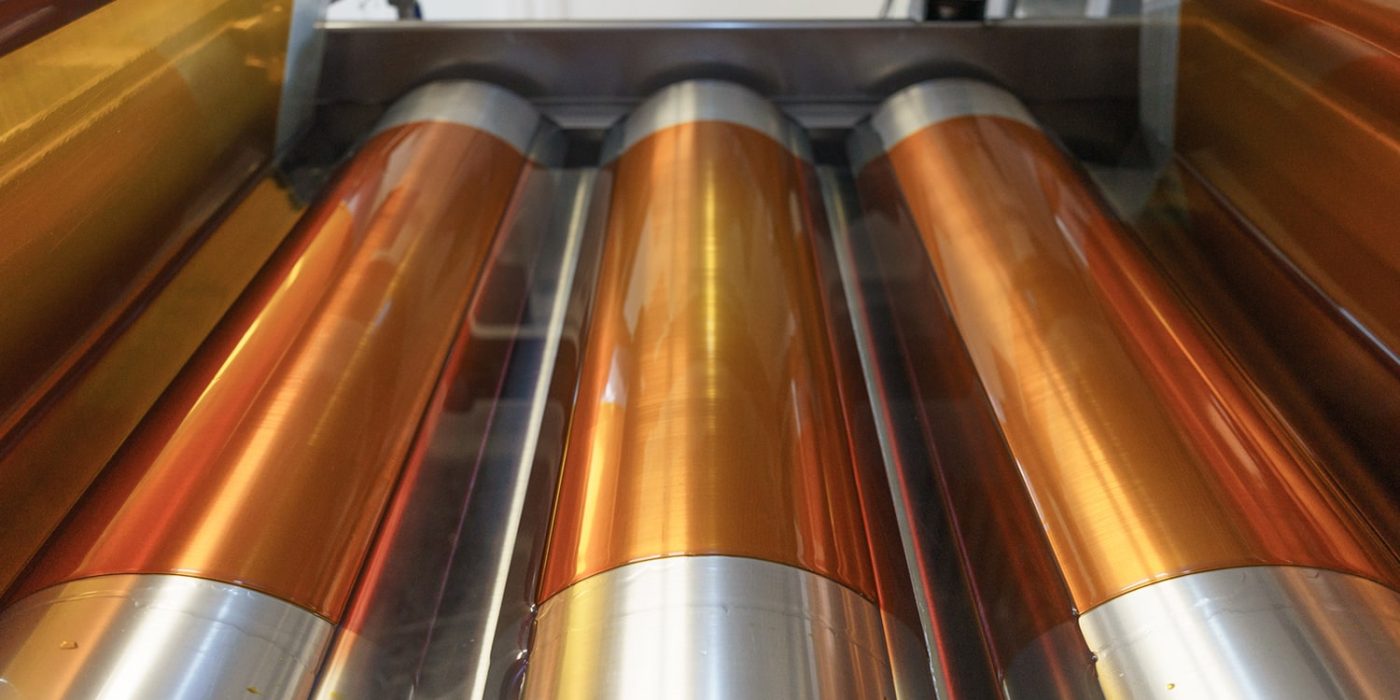

The agreement also defines BASF’s role in expanding MEA production at Advent’s planned state-of-the-art manufacturing facility in Western Macedonia, Greece. It secures Advent access to the entire product and service portfolio to establish a circular economy for critical materials.

BASF unit supplies membrane and MEA technology for high-temperature proton exchange membrane (HT-PEM) fuel cells. Advent is the largest manufacturer of HT-PEM fuel cell systems, which will also be made available for heavy-duty transport and the marine industry. The partnership aims to combine Advent’s expertise in fuel cell stacks and systems with BASF’s know-how in developing catalysts and membranes.

To that end, the companies will collaborate on BASF’s new membrane development Celtec-Z and Advent’s new membrane concept Ion Pair MEA. The goal is to improve aspects such as performance, durability and competitiveness in terms of cost.

“We are committed to building a full loop supply chain for green hydrogen technologies, including precious metal services, catalysts, components and recycling. Expanding our longstanding cooperation with Advent enables us both to grow in the HT-PEM fuel cell market and helps position Europe as a leading region for the hydrogen industrial transformation,” says Tim Ingle, Senior Vice President, BASF Environmental Catalyst and Metal Solutions.

The HT-PEM fuel cells operate at a cell temperature of 120 to 180°C. According to BASF, they enable the utilization of impure hydrogen, allow simplified cooling and do not need to be humidified. Therefore, these fuel cells do not need high-purity hydrogen but can also use a lower degree of purity, which can be produced on board the vehicle by reforming methanol, eMethanol, natural gas and various other renewable fuels. Advent currently offers such fuel cells for stationary and portable applications but plans to sell them for heavy-duty transport and the marine industry.

These HT-PEM fuel cells will also be manufactured in a new plant in Greece, specifically in Western Macedonia – with the help of BASF technology. “This partnership will enable the combination of Advent’s expertise in fuel cell stacks and systems with BASF’s expertise in catalyst and membrane development, creating a powerful synergy that will drive innovation in the fuel cell industry”, says Vasilis Gregoriou, Advent’s Chairman and CEO.

Moreover, Advent Technologies has signed a contract with an unnamed manufacturer to deploy HT PEMs and MEAs in fuel cell trucks in Asia. The deal is said to have a combined value of $1.1 million. Deliveries of the HT-PEM MEAs will begin this quarter and, according to Advent, have a “projected continuation of deliveries in accordance with the customer’s specified timeframe”.

advent.energy, basf.com (agreement BASF), advent.energy (Asia)

0 Comments