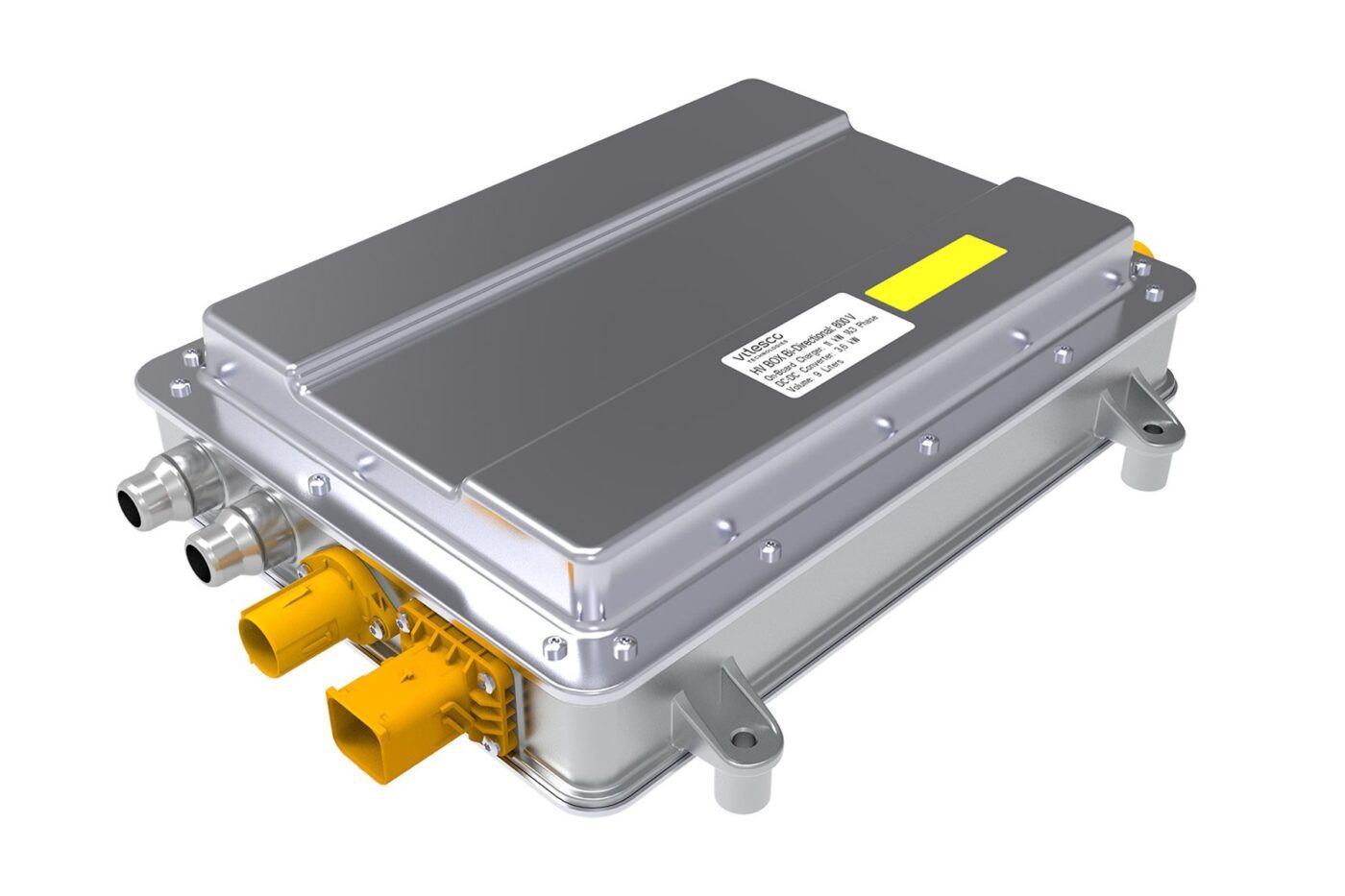

Vitesco prepares ‘high-voltage box’ for series production

According to Vitesco, the modular system is designed to make “charging, converting and distributing electricity in electric vehicles more cost-effective” by integrating several functions into one unit, depending on the design: The charger for AC charging on the mains with up to 22 kW of power, a DC converter that supplies power for the 12-volt mains in the car, power electronics that distribute high-voltage energy in the car and allow DC charging with up to 800 volts.

When developing the vehicle, car manufacturers no longer have to integrate several components into their overall system, but just one. Particularly in the case of standard components such as the onboard charger for AC charging or the rectifier for the 12-volt vehicle electrical system, the car manufacturer can’t really stand out if they decide in favour of supplier component A or B – as long as the efficiency is similar.

As Vitesco pre-integrates the individual components, the space requirement in the vehicle should also be reduced. The onboard charger, the DC/DC converter and the power electronics can also use a common cooling system in one housing – previously, each component required its own cooling units at a different location in the vehicle. The cabling between the components can now also be simpler if they are housed in a common housing. Vitesco does not specify how much the space requirement will be reduced – the modular system can cover different functions depending on customer requirements and therefore also requires different amounts of space.

The supplier also relies on silicon carbide semiconductors for its high-voltage box, which should give the charging system “an efficiency of more than 95 per cent”. “The sophisticated power electronics ensure that this system not only offers efficiency but also electrical safety,” says Vitesco. According to the company, the unit will cover “all relevant European and global grid topologies”.

For one of the two series orders, the high-voltage box already supports bidirectional charging, meaning it can also supply alternating current of up to 230 volts to connected consumers or the power grid if required. The company is driving forward the necessary standards with its experts in key committees and is thus helping to decide where development is heading. As is customary in the supply industry, Vitesco does not specify which customers are involved in the high-voltage box.

However, as Renault is also talking about a new onboard charger for the recently unveiled Renault 5, which is capable of bidirectional charging, this could be an indication that the French company is one of the first customers for the Vitesco development. “The direct current to alternating current converter, which converts the 400 volts from the traction battery into 12 volts, and the control box for power distribution are integrated into the charger to save space,” Renault wrote regarding the technology in its new small electric car.

“On a day-to-day level, charging, energy conversion and power distribution are just as relevant for a driver’s satisfaction with a vehicle as driving itself is,” says Thomas Stierle, Member of the Board and Head of the Electrification Solutions Division at Vitesco Technologies. “With our High Voltage Box, we integrate these core tasks of energy management into one efficient and compact unit. This integration makes electrification on a large scale and at low cost easier.”

0 Comments